Test and review of the Creaform Go!SCAN 50, a professional-grade portable 3D scanner

Introduction

Creaform headquarters are based near Québec City, Canada. The 3D scanner company launched its first hardware product, the HandySCAN, in 2005, with software which was then called VXscan.

Creaform’s mission is to develop, manufacture and market cutting-edge portable 3D measurement systems which increase productivity. Through its expertise, Creaform helps companies from the manufacturing industry to create, simulate, verify, and collaborate in 3D. In 2013, Creaform reported annual sales of around $52 million.

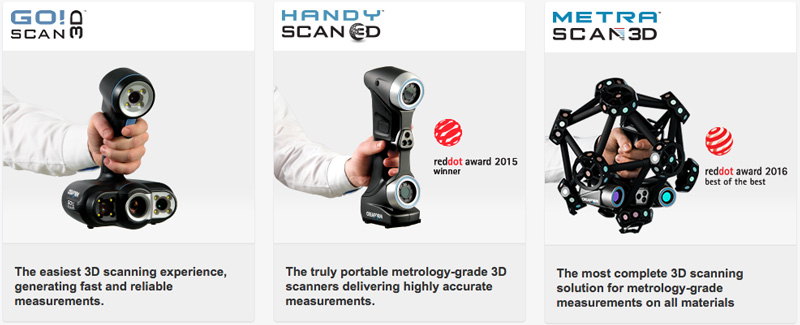

Creaform lineup of portable industrial 3D scanners includes 5 different products. The Go!SCAN 3D, HandySCAN 3D, the HandyPROBE, the MetraSCAN 3D and the MaxSHOT.

The most affordable portable 3D scanners offered by Creaform belong to the Go!SCAN 3D product line: the Go!SCAN 50 and the Go!Scan 20.

- The Go!SCAN 20 is suited for scanning small parts with intricate details, with a resolution of 0.100 mm (0.004 inches) within a 3D scanning area of 143 x 108 mm (5.6 x 4.3 inches). Hence the recommended part size is 0.05 – 0.5 m (2 – 20 inches). The Go!SCAN 20 has a slightly different design and color compared to the Go!SCAN 50.

- With its larger field of view, the Go!SCAN 50 is a good match for 3D scanning medium to large objects, with a recommended part size of 0.3 – 3.0 m (1 – 10 feet). The Go!SCAN 50 offers a 3D scanning area of 380 x 380 mm (15 in x 15 in), with a maximum resolution of 0.5 mm (0.020 inches).

In addition to the standard industrial use cases – including product design, manufacturing, and quality control – the Go!SCAN 3D products are also popular in education, museology, heritage preservation, and virtual reality.

Today, we are doing a hands-on review of the fast and flexible Go!SCAN 50.

Discovering the Creaform Go!SCAN 50

We have been invited by the Creaform team in Tokyo to visit their office and perform a hands-on review of three of their portable 3D scanners, the MetraSCAN 750, the HandySCAN 700, and the Go!SCAN 50. This hands-on review focuses on the Creaform Go!SCAN 50.

The Creaform Go!SCAN 50 is a portable solution for flexible 3D scanning. This portable 3D scanner uses structured light 3D scanning technology. When switched on, the Go!SCAN 50 flashes a light that embeds a specific pattern. This pattern looks like some sort of a giant QR code cast on the object by a video projector.

| Technology | Structured light |

| Max resolution | 0.5 mm |

| Weight | 0.95 kg |

| Price | upon request |

The topology of the part or object being captured causes the casted light to be deformed. The two cameras of the Go!SCAN 50 registers this deformation and the software is then able to compute the 3D properties of the object.

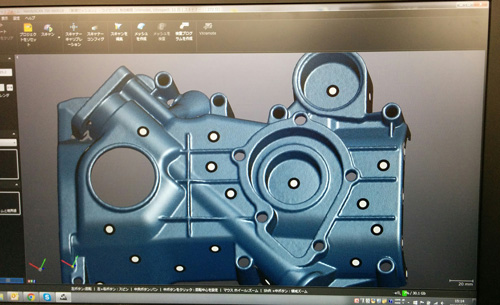

The data is captured as a colored dots cloud which is used to generate an accurate 3D mesh – basically, several thousands of polygons in a 3-dimensional space, on which a texture mapping (the color) can be applied.

Getting started with the Creaform Go!SCAN 50

Packaging

The Creaform Go!SCAN 50 is packaged in a rugged protective hard case, build with very strong plastic, and fitted with thick protective foam.

Included in the transport case is the connectivity cable of the device, which splits up as a connectivity cable to the computer and an alimentation cable. The connectivity cable plugs to USB 2.0 plug on a computer while the alimentation cable requires an AC plug.

Calibration process

This professional metrology equipment requires a specific calibration process in order to function properly.

The calibration plate is a nice finished plain flat wooden box. It contains some warnings and a white area covered with several specifically placed targets. In total, the calibration process takes less than 2 minutes and simply requires the user to follow simple steps in the Creaform VXElements software (VXElements is the data acquisition platform for all Creaform scanners).

Testing the Creaform Go!SCAN 50

The sensor itself weighs 950g and is quite compact: 150 x 171 x 251 mm (5.9 x 6.7 x 9.9 inches). The distribution of weight is ergonomic, with most of the heavy parts (color module, projector, and one camera) positioned towards the bottom of the Go!SCAN 50.

The handle of the device is very comfortable and has a very ergonomic feel. However, if you intend on using the 3D scanner for a long capture time, it is better if you have big hands since the handle itself is quite big.

The trigger-like button is activated by a soft touch with the index finger, to start and stop the 3D scanning process. The Go!SCAN 50 itself is connected to a computer via a USB 2.0 port.

There is only one cable coming out of the 3D scanner. This cable splits in two after a few meters, into a USB connection for the computer and an alimentation cable to be connected to a standard AC wall socket. Compared to some competitors which rely on two cables, the single cable is a big advantage for mobility and flexibility while 3D scanning.

The laptop we used in this demonstration is the recommended computer, provided in this test by Creaform. It’s a powerful HP laptop with a Windows 7 OS 64 bits, 32 Gb of RAM, an Intel Core i7, and an Nvidia Quadro K1100M GPU.

We do not recommend a less powerful configuration, as 3D scanning requires a lot of computing power. Windows 10 is not officially supported yet but we heard that some Creaform customers use it successfully.

Reverse engineering use case

The part we used to perform this test is a small plastic part, very similar to a random mechanical part. It is quite complex with a lot of features and small intricate details. Note that this specific material is ideal for structured light 3D scanners because it does not reflect the light.

The 3D scanning process with the Go!SCAN can work two different ways: with or without targets.

- Without targets: the Go!SCAN 50 uses the distinctive geometrical properties of the part to 3D localize the data it gradually generates. For tracking reasons, the 3D scanning process without targets has one restriction: the object must offer a distinctive feature or texture every 380 x 380 mm scanning area (like a hole, a bump, a groove, etc…). If that’s not the case, VXElements is not capable of knowing the distinction between the different parts of the objects and where to spatially position them. A typical example of such a challenging part would be a long uniform pipe. For the same reason, issues may arise if a similar pattern is repeated several times on a larger scale.

- With the optional targets: it is possible to use targets to compensate for an object’s lack of distinctive features. The targets are small round stickers that can be placed on the surface of the object to be captured. The targets compatible with the Creaform Go!Scan 50 has a limited number of uses and does not come cheap (around $0.1 each). Note that the more accurate Go!SCAN 20, with its smaller field of view, works with smaller targets. It is recommended to position these targets every 20 – 100 mm (0.75 – 4 inches) to allow good tracking for the Go!SCAN 50.

For this test, we scanned the part without using targets. In less than 5 minutes, we obtained a very detailed 3D scan of the complex surface of the part.

The Creaform Software called VXElements performs real-time fusion: the 3D scans are automatically fused to generate one unique mesh.

Thanks to VXElements advanced tracking algorithm, it is possible to locate a part that has been moved and to directly add data to the existing dots cloud.

The 3D scanner captures the part using the resolution specified in the software scanning panel. When the user chooses a specific capture resolution (let’s say 1 mm), it is possible to change it afterward in the software (like with a RAW file of a photo). Therefore, the output resolution can also be edited according to the user’s needs.

The Go!SCAN 50 is limited to a 0.5 mm maximum resolution. In any case, there is no interest in input in the software a lower value than this because it is its physical limit. Other Creaform 3D scanners can go lower, however, as the Go!SCAN 20 which can reach 0.1 mm.

At any given step of the 3D scanning process, it is possible to remove or add data to obtain a more accurate and defined mesh. It is also possible to select and delete erroneous data and targets, and even some missed frames, thanks to the very useful 3D scanning tree inside VXElements, a feature very similar to most CAD tools’ design tree.

VXelements is the basic capture package included with all Creaform 3D scanners. VXmodel, VXtrack, VXinspect, and VXremote are software modules bringing in additional features (beyond data capture) and are sold separately.

- VXinspect allows users to compare a CAD model to the scanned data, which is very useful for reverse engineering and metrology applications.

- VXmodel is a post-processing software that directly integrates into VXelements. VXmodel allows the finalization of 3D scan data to export it as a readable 3D file for 3D printing and CAD software (CATIA, SolidWorks, Inventor…)..

- The VXtrack tracking module has numerous applications such as calibration and capture guidance, monitoring of complex assembly processes, real-time compensation of machining tool-generated errors, and monitoring of deformations during testing and can be useful in various industries such as aerospace, automotive, robotics, biomechanics, and non-destructive testing. We have not tested it as it was mainly designed to be used with the Creaform MetraSCAN 3D scanners.

- VXremote enables users to visualize real-time scanned data and change parameters, even when they are far from the connected laptop. VXremote is particularly useful when scanning large objects or when the scanning operation has to be performed in constrained or remote areas. VXremote is compatible with Creaform-certified rugged tablets (available in 7″ or 10″ size).

3D face scanning

After the reverse engineering use case, the Ametek team offered to 3D scan my face. The face 3D scan was conducted very quickly and the result is impressive, with a great level of detail. The Go!SCAN 50 is regularly used for 3D body scanning and forensics applications (crime scene 3D scanning).

The texture of the 3D generated file is well-detailed thanks to the Go!SCAN 50 sensor, which delivers a texture resolution between 50 and 150 dpi, coded in 24 Bits. Like all 3D scanners based on structured light, the Go!SCAN 50 does not work very well on hair, especially when they are dark and/or curly.

Tip: to deal with the challenging yet common use case of 3D scanning hair, it is recommended to apply water on them to make them appear as a “solid” block.

Conclusion

The Go!SCAN 50 is a flexible and rapid 3D scanning system, designed to address a wide range of professional needs, from industrial use cases to more specific applications such as cultural heritage conservation, education, virtual reality, arts, and even architecture.

The 3D scanning process is fast and flexible thanks to the unique cable connecting the 3D scanner. The great features and user experience of VXElements play a huge part in the overall performance of the Go!SCAN 50. In our opinion, the software component is a key competitive advantage for the Go!SCAN 50 when compared to its competitors.

Our experience is however limited with this product and our review only reflects the hands-on experience we add with the Go!SCAN 50, under the Ametek team supervision.

The Go!SCAN 50 has very few competitors and for professionals able to afford it this is one of the best options on the market. For people looking for a higher resolution on smaller objects the Go!SCAN 20 is also an interesting solution. When more performance is required, we recommend the HandySCAN 700 or the MetraSCAN 3D scanners, but these are more expensive.