Fast 3D printing

What if 3D printing was faster ?

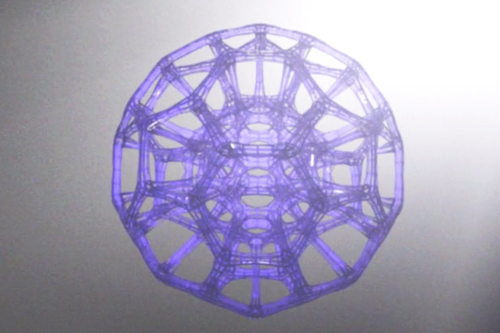

3D printing the 50 mm diameter object on the left with regular techniques, such as Filament Fused Fusion (FFF) or Stereolithography (SLA), takes between three to eleven hours. Bigger objects can take several days to print, even with a 3D printer working day and night.

Thus, fast 3D printers have a huge competitive advantage. Several companies have introduced new technologies for speeding up the 3D printing process. Those innovations work with plastic-based materials and rely on continuous printing technologies.

Fast 3D printing technologies

DLS (Digital Light Synthesis) by Carbon3D

Carbon3D’s technology is a chemical process that balances light and oxygen to selectively photo cure liquid resin.

It works by projecting light through an oxygen-permeable window into a reservoir of UV curable resin. The build platform lifts continuously as the object is grown without requiring more time-consuming steps. By controlling the oxygen flow, it creates a thin layer of uncured resin between the window and the object.

Carbon3D calls this thin layer the “Dead Zone”. The video below illustrates the technology:

This technology makes it possible to grow the object without stopping; a continuous sequence of UV images is projected and the object is drawn from the resin tank without interruption.

Carbon3D’s technology is 25 to 100 times faster than other 3D printing techniques. An additional advantage of this resin 3D printing technology is the resistance of the 3D printed objects, which have no weaknesses between layers.

Animated printing at super speed by Gizmo 3D

Gizmo3D is an Australia-based company directed by Kobus du Toit. Their products use top-down Digital Light Processing (DLP) 3D printing.

In their line of 3D printers, the projector that cures the resin is located above the resin tank. This position avoids suction issues which usually happen with bottom-up 3D printing processes. The build plate continuously moves downward during this fast 3D printing process, with no interruption.

Multi Jet Fusion (MJF) by HP

The computer and printer giant Hewlett-Packard revealed in 2014 their first 3D printer. This machine uses their patented Multi Jet Fusion (MJF) technology to open new possibilities.

The 3D printed objects are resistant, detailed, and fast to print. The company claims a dramatic decrease in production time. MJF is 10 times faster than Selective Laser Sintering (SLS).

Multi Jet Fusion technology by HP is up to 25 times faster than other 3D printing technologies such as filament extrusion. HP manufactures both metal 3D printers and full-color 3D printers.

Continuous Additive 3D Printing Technology by Carima

Carima is a South-Korea-based 3D printer manufacturer. Their 3D printers use innovative technology C-CAT, based on Digital Light Processing (DLP) 3D printing technology.

The C-CAT (Carima-Continuous Additive 3D Printing Technology) is a super-fast 3D printing technology. Like Carbon3D’s CLIP process, C-CAT is a continuous DLP technology that can produce objects at amazing speeds.

According to Carima, C-CAT technology can print 60cm3 per hour with a layer thickness of only 0.001 mm. C-CAT offers incredibly fast 3D printing compared to existing speeds of DLP 3D printing (which are around 2-3cm³/hour @ a layer thickness of 0.1mm).

The 3D printing process C-CAT is up to 400 times faster than regular DLP 3D printers.

Intelligent Liquid Interface (ILI) by NewPro3D

NewPro3D is a company based in Vancouver, Canada. In late 2015, the company introduced its super-fast 3D printing technology, ILI (Intelligent Liquid Interface).

The NewPro3D team explains that their innovation relies on a “transparent, wettable membrane between the photo-curing resin and the light source”. They claim that they can achieve a 3D printing speed up to 150 times faster than SLA (Stereolithography) technologies and 40 times faster than PolyJet 3D printing technologies.

English

English  Français

Français