Outsourcing vs in-house manufacturing: Should you choose a service or buy your own equipment?

What’s a manufacturing service?

A manufacturing service provider like Xometry enables companies to outsource their part production, an increasingly popular business model also known as Manufacturing as a Service or MaaS for short.

On-demand services can also be used for rapid prototyping, a process in which businesses can quickly create functional prototypes, use iterative design methods, and reduce their time to market.

Several types of fabrication methods exist, including subtractive (e.g. CNC machining) and additive (e.g. 3D printing) manufacturing technologies.

The process is simple: you upload your 3D file, receive a quote – instantly, in the case of Xometry–, place your order, and have your part(s) delivered to your office.

Here’s an example showing how smooth the outsourcing workflow can be:

Is it best to use a service or produce in-house?

The typical answer will be “it depends”. It does, and on a variety of factors. Here are a few important questions you should ask yourself before making a decision.

Do you need to have various technologies and materials at your disposal?

Some parts are better off 3D printed if they’re complex, while other, basic parts have a much lower unit cost if they are made by injection molding. Having a machine for each manufacturing method is unrealistic in most situations, both in terms of investment and logistics.

Plus, there is no universal machine that can use all types of materials (metal, high-performance plastics, composites, …).

With a manufacturing service, you can pick and choose your method, material, and surface finishing depending on your needs, no strings attached.

You can also try out new techniques. If you’ve traditionally been manufacturing your products or tools with injection molding and would like to see if 3D printing can open new doors, a 3D printing service is the ideal way to see if it’s worth a shot.

Are you manufacturing in quantities that would justify investing in an expensive machine?

If you’re manufacturing hundreds of parts per week, then you’ll probably want to estimate your cost-per-part in both scenarios. It can be a tricky calculation, though, because it doesn’t just come down to amortization and material costs.

Ramping up your team’s technical knowledge or hiring an expert technician to oversee your operations also come into play, as well as everyday maintenance and failure rates.

The latter is especially true with 3D printing. Obtaining high-quality 3D printed parts requires quite a bit of experience and fine-tuning. 3D printing service providers have their machines operated and maintained by experts and engineers that know exactly what a specific design will need (part orientation, print speed, temperature settings, etc.).

Hence, if you are looking to run small production series, or if you’re going to do some rapid prototyping on a non-frequent basis, going through a service is likely the better option.

If you are indeed ready to implement a new manufacturing method in your business, you can also use a service to weigh your options in terms of materials, specific machines and technologies, finishing techniques and coatings, … Mix and match until you find the perfect combination.

Why should I choose a service provider like Xometry?

Xometry is one of the industry’s most trusted providers, a worldwide reputation based on years of reliable service, an intuitive interface, and expert guidance.

Multiple technologies centralized in one place

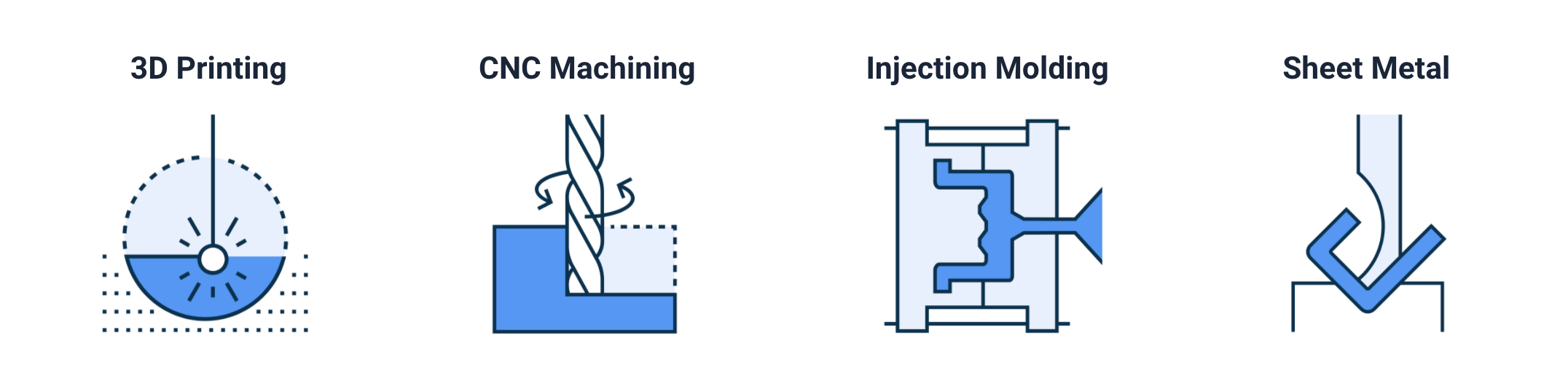

Their 5,000+ partner network and their fleets of industrial, high-throughput machines cover the four main manufacturing methods that exist today: CNC machining, injection molding, sheet metal fabrication, and 3D printing.

3D printing alone englobes another range of technologies such as Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and much more.

Part inspection and certified quality

Xometry is fully geared to guarantee your part quality thanks to a host of machine and material certifications as well as inspection services that can be tailored to your requirements.

The 2-minute video below illustrates how NASA, for example, used Xometry’s CNC machining service to manufacture large, critical parts while resting assured that these parts would meet their strict, life-dependent standards (tolerances, mechanical properties, …).

If you’re not sure whether you should use an on-demand manufacturing service for your project, you can try Xometry’s instant quote engine or book a demo with their team.

English

English  Français

Français