Dramatic increase in productivity—HBD 350 Empowers Shoe Mold to Successfully Reduce Weight by 1.6KG

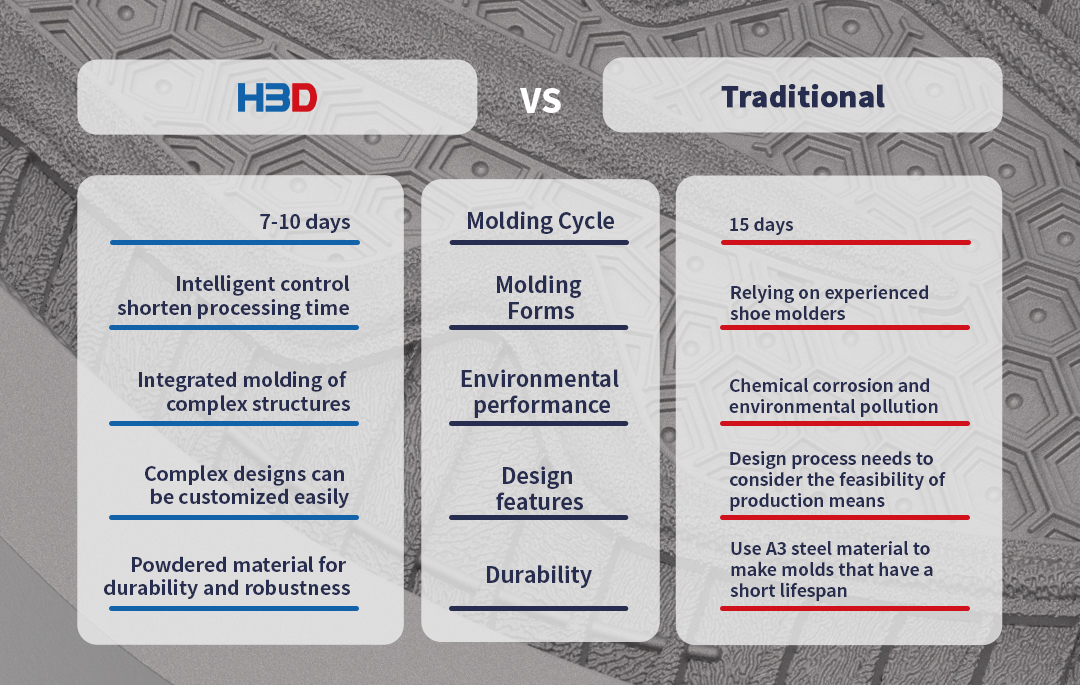

In the ever-evolving landscape of shoe mold manufacturing, a groundbreaking trend is taking center stage. 3D metal printing technology (LBPF) is emerging as the game-changer, outshining the traditional CNC machining methods. This innovative approach offers unmatched precision, unparalleled efficiency, and rapid production capabilities, elevating the industry to new heights. As shoe manufacturers worldwide embrace this transformative shift, they unlock a world of possibilities, enabling them to deliver superior products with reduced lead times and increased customization options.

VS

Solution

Improved production efficiency

.

Design Flexibility

Gives designers a high degree of freedom to realize product innovation

Cost Reduction

High intelligence saves labor and material costs.

Energy-saving production

.

Utilizes lightweight 3D printing material

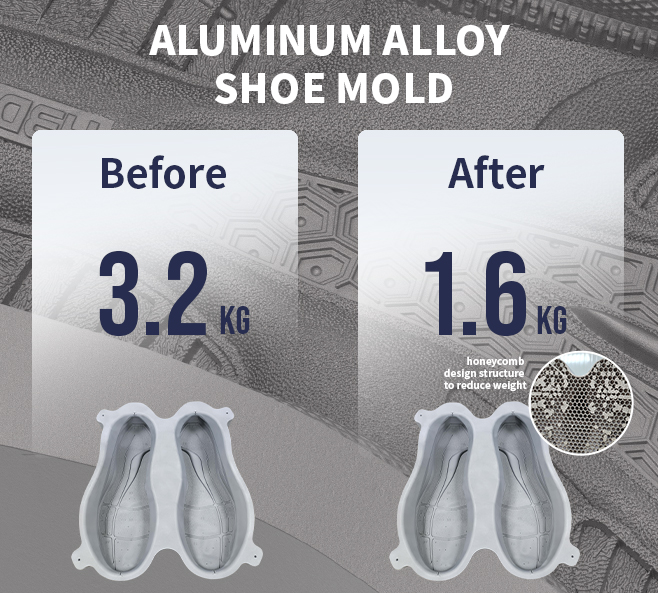

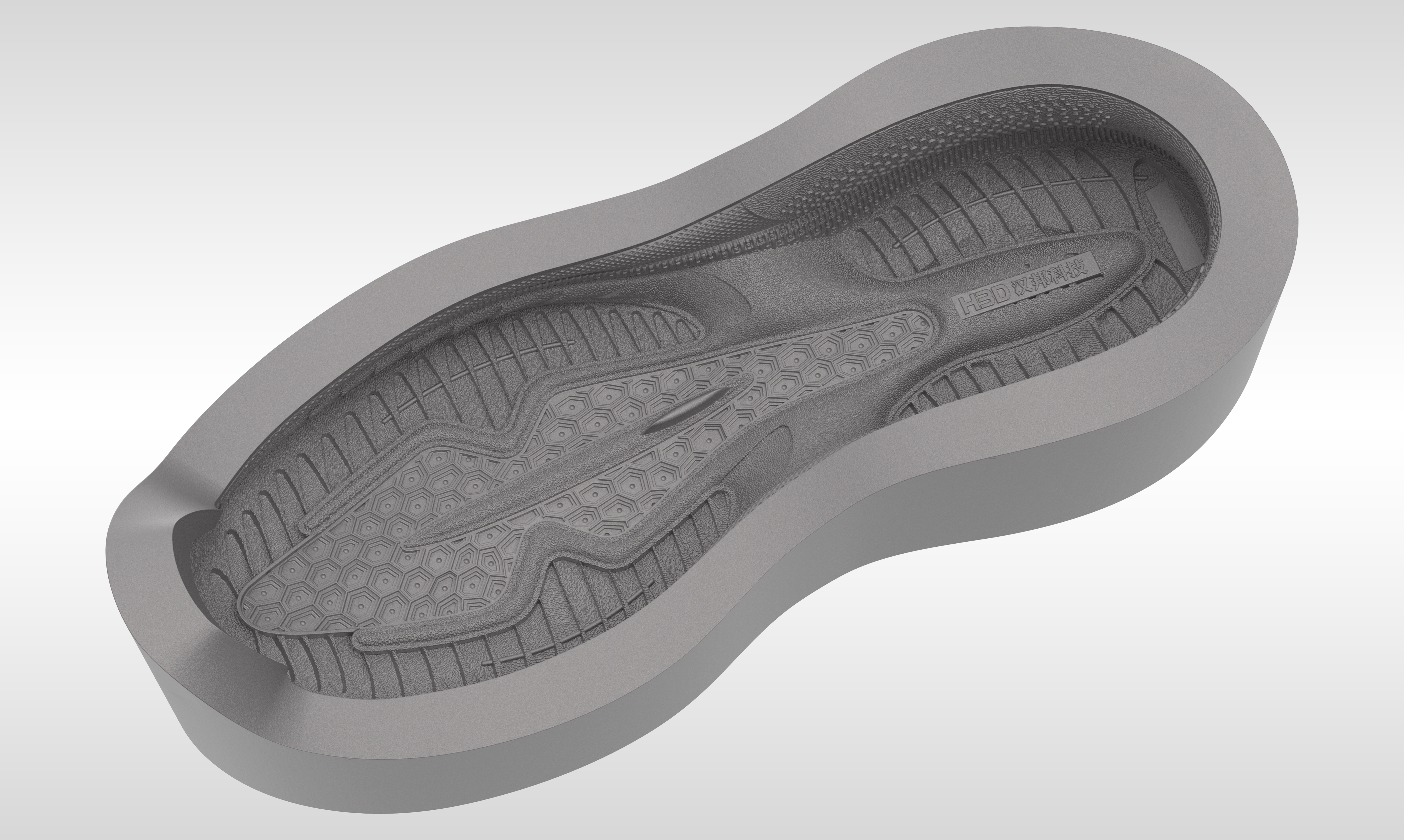

In the shoe mold industry, the best choice for crafting EVA molds is the use of aluminum alloy material. Aluminum alloy has a density of only 36% compared to typical mold steel, which significantly reduces the weight of the entire mold set. Additionally, aluminum alloy boasts a high thermal conductivity, allowing for the rapid absorption and release of heat, reducing cooling time by 50%, and thereby enhancing mold production efficiency.

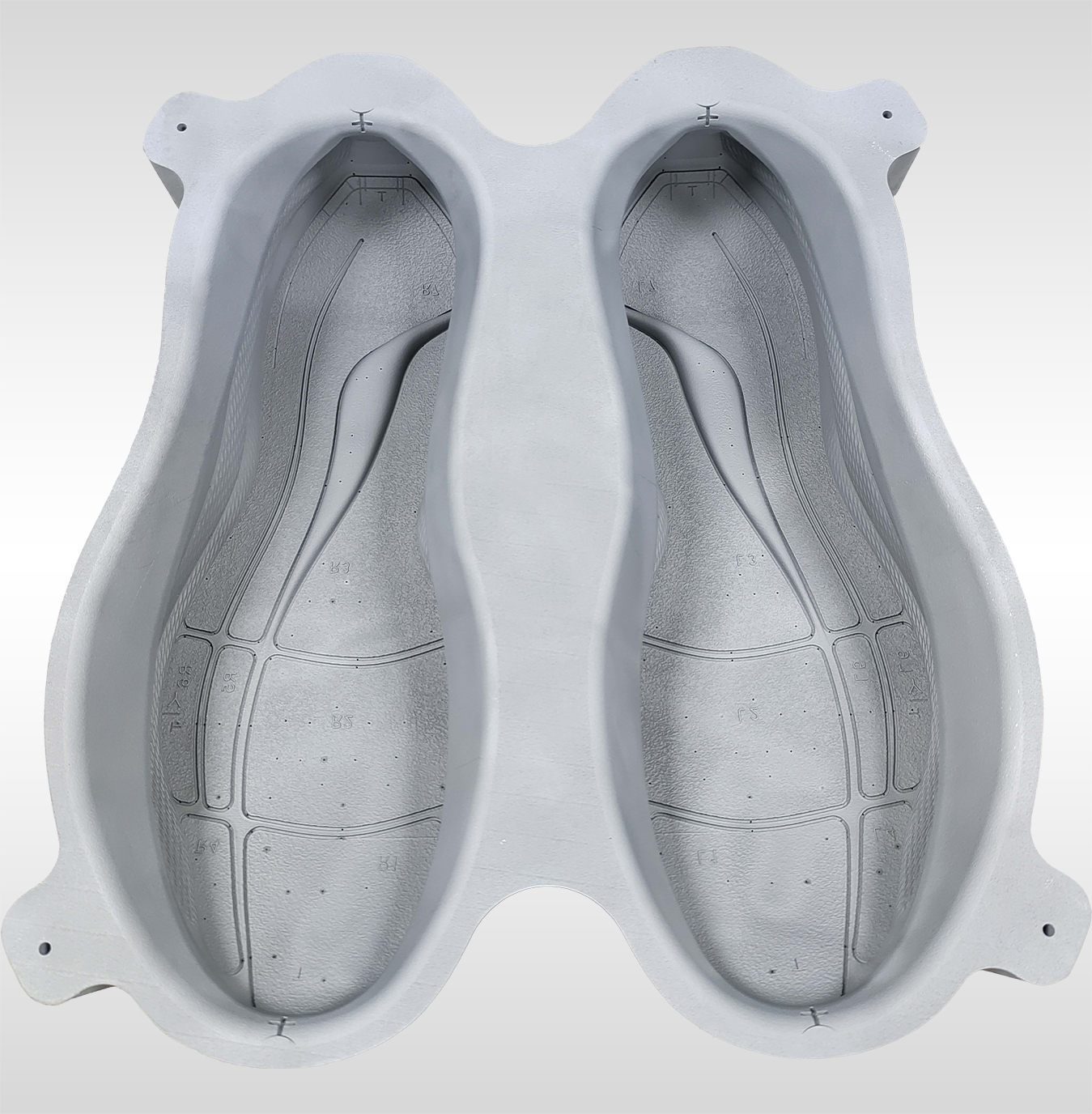

Multi-layer printing combined with honeycomb lightweight structure

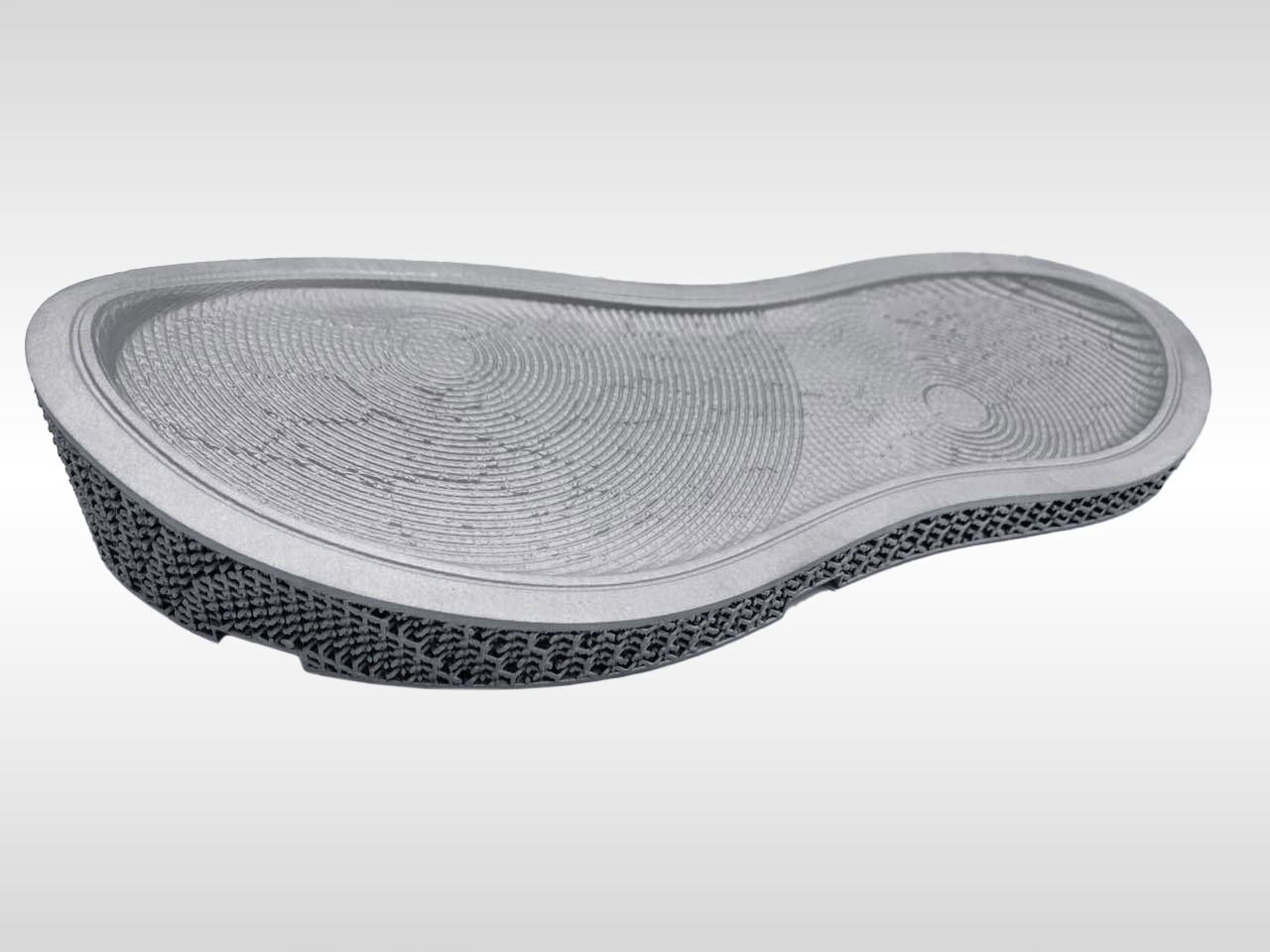

HBD 350 Metal Additive Manufacturing Equipment, combined with multi-layer thick honeycomb lightweight technology, reduces the weight of shoe molds to 1.6kg, achieving a 50% weight reduction. The cutting deformation of the shoe molds can be controlled within 0.4mm.

By employing a thin layer thickness of 30 micrometers and fine printing settings for intricate patterns, and utilizing a thicker layer thickness and high-speed settings for printing the solid sections of the shoe mold, we ensure both the precise formation of surface patterns and an enhanced printing efficiency.

HBD Aluminum Alloy Shoe Mold Case

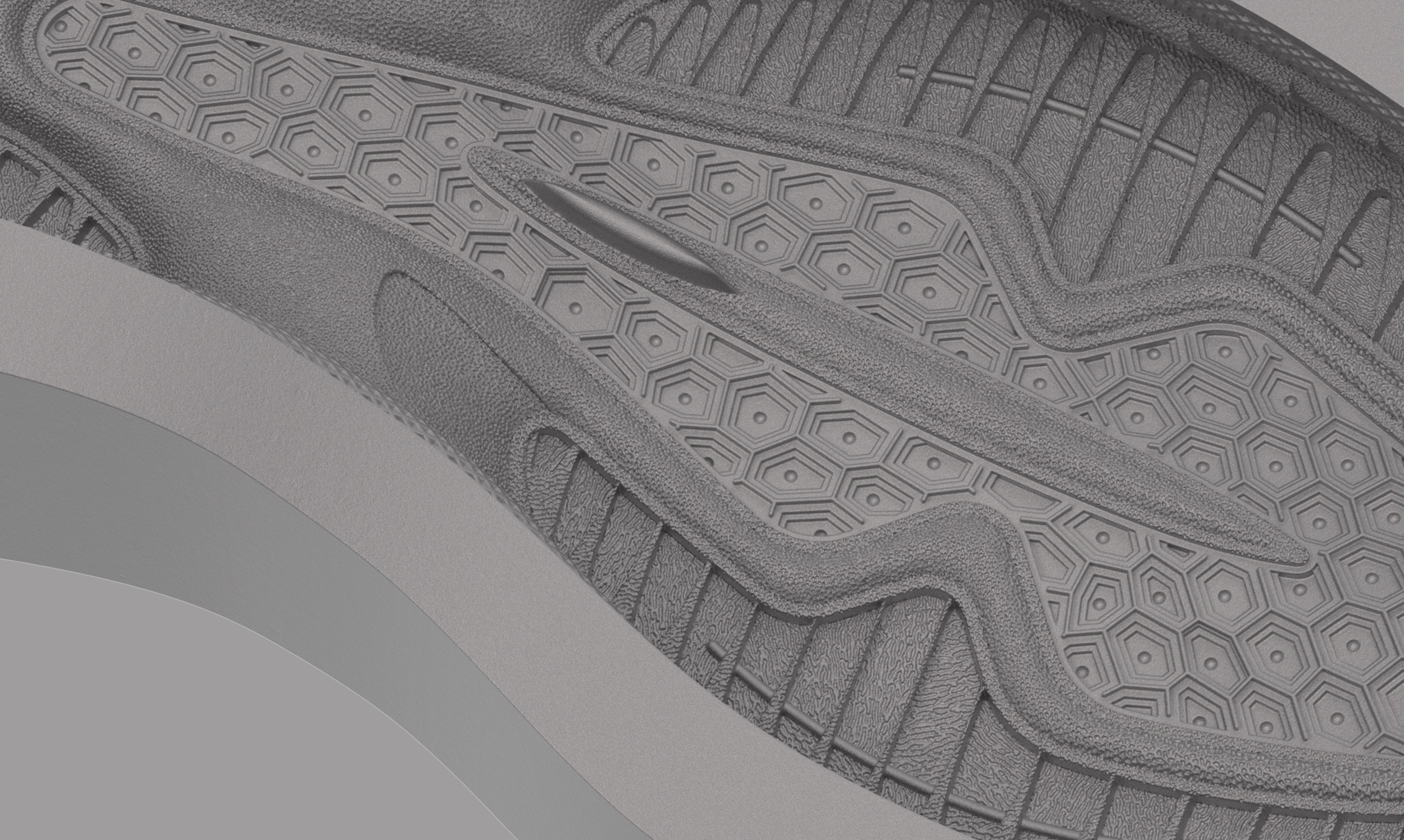

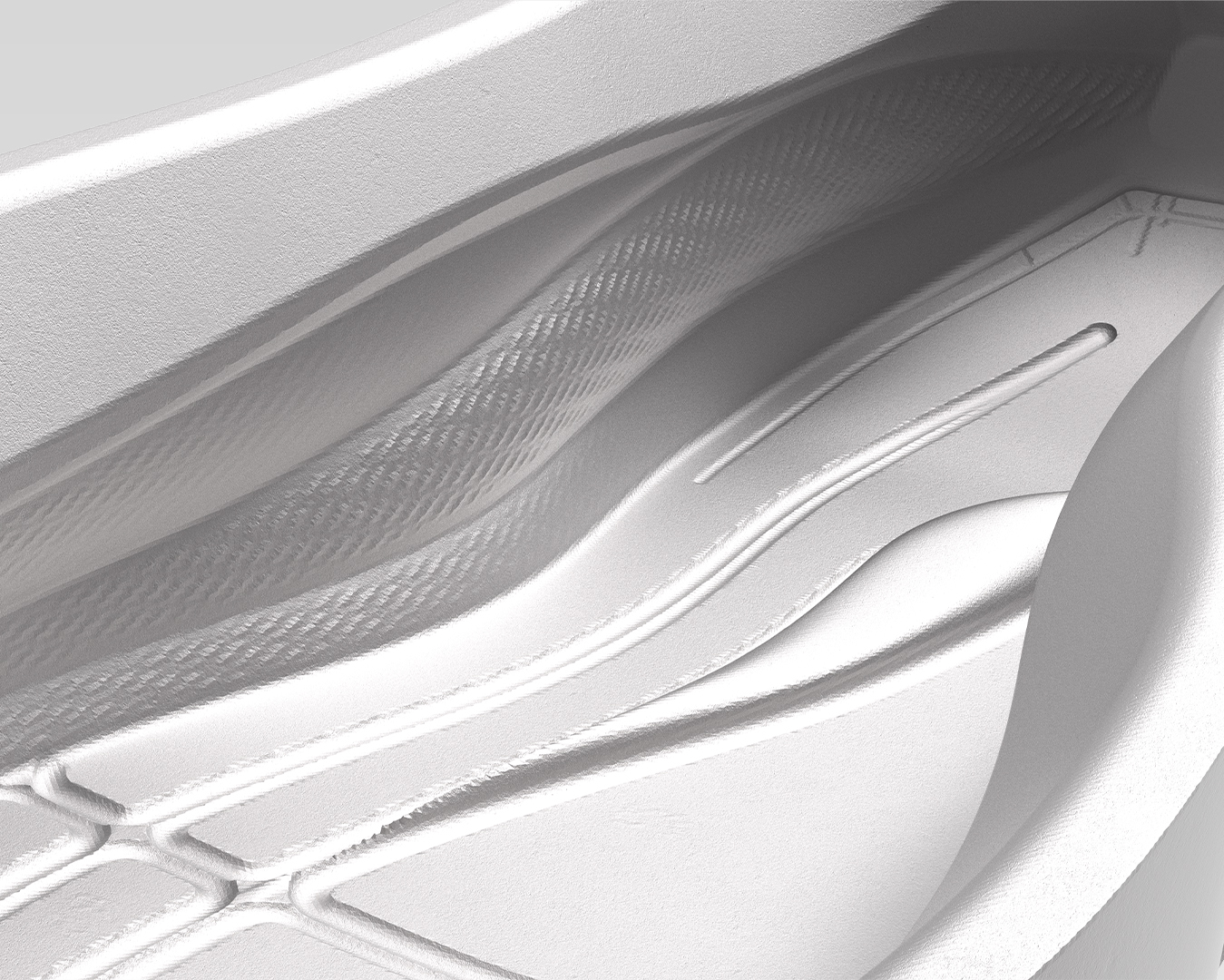

Clear and delicate surface patterns on shoe molds

Partial display of the sidewall pattern effect on the shoe mold

This aluminum alloy shoe mold features numerous intricate pattern structures in its overall design. Due to the broad formation melting pool characteristics of aluminum alloy material, printing small pattern structures using normal parameters can result in blurred patterns and reduced strength. However, by utilizing HBD metal additive manufacturing equipment and adjusting process parameters, we can achieve the desired pattern formation to meet customer requirements

The bottom is designed with a lattice structure, reducing the overall weight of the shoe mold. The 3D texture of the shoe mold’s surface, printed using HBD 350 metal additive manufacturing equipment, shows remarkable depth, surpassing traditional design methods. This breakthrough enables a shorter shoe mold design and manufacturing cycle.

HBD 350 METAL AM SYSTEM

Efficient Production

Large Layer Thickness / Mixed Layer Thickness Printing Scheme Meets the demand for efficient batch production of molds.

Safe and Stable

Enclosed fully automatic powder recycling system reduces direct contact between operators and powder.

Precision Control System

One-click start, automatic data detection. Simple operation for higher efficiency.

Accurate Positioning

0.1mm positioning accuracy Allows for high-precision shoe mold texture processing.

HBD 350 Metal Additive Manufacturing Equipment Enables Rapid Delivery of Printed Cores in 7-10 Days, Reducing Mold Production Cycle by Over 50% Compared to Traditional Methods, Facilitating Efficient Manufacturing and Achieving Quick Mold Delivery.

English

English  Français

Français