Pellet 3D printing

As a raw material format, pellets are most commonly associated with forming processes like injection molding. However, some 3D printers are fitted with pellet hoppers and extruders instead of filament extruders.

There are several benefits to pellet extrusion, including low material cost compared to filament, the ability to use recycled materials, and the ability to print very large parts (thanks to wider nozzles and faster material flow).

Pellet-extruding 3D printers are often built for construction or other large-format printing projects.

Source: Tumaker

Related content

Featured pellet 3D printer

Compare

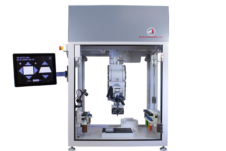

Pam Series P

Pollen AM

Product data validated by the manufacturer.

| Technology | Material Extrusion |

| Materials | Thermoplastics |

| Feedstock format | Pellet |

| Build envelope | ⌀ 300 × 300 mm |

| Country | France |

From

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ...).

$ 65,000

English

English  Français

Français