Clay 3D printer selection and guide

What is clay 3D printing?

The practice of pottery and clay sculpting goes back more than 20,000 years, and the survival of clay artifacts has contributed greatly to our understanding of human culture.

But clay forming isn’t just ancient history. In fact, new technologies like clay 3D printing are opening up brand new possibilities in the creation of pottery, sculpture, and even architecture.

Clay 3D printing is basically a combination of two existing processes: coiling, a millennia-old technique for building large vessels using long strands of clay stacked on top of one another; and extrusion-style 3D printing, a contemporary digital manufacturing process and the most common additive manufacturing technology found in desktop 3D printers.

The 3D printing of clay is similar to the 3D printing of thermoplastics, just without the need for a “hot end” on the extruder. A clay 3D printer squeezes out strands of clay and deposits the material in layers according to computer instructions. The result is a 3D clay structure that can then be heated up and solidified just like a handmade clay object.

Clay 3D printers all use extrusion technology to print wet clay. They are therefore different from other ceramic 3D printers which use powders or other materials.

You may also like:

Ceramic 3D printing 2024: guide and ceramic 3D printer selection

2023 Clay 3D printer selection for professionals

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| WASP

Product data validated by the manufacturer.

| DeltaWASP 2040 Clay | ⌀ 200 x 400 mm | Italy | $ 3,500 | Quote |

| StoneFlower | 4.0 Multimaterial 3D printer | 500 × 500 × 800 mm | Germany | $ 4,000 | Quote |

| VormVrij | LUTUM 4.5 | 430 × 450 × 500 mm | Netherlands | $ 6,000 | Quote |

| 3DPOTTER | 3D PotterBot 10 Pro | 415 × 405 × 500 mm | – | $ 6,105 | Quote |

| WASP

Product data validated by the manufacturer.

| DeltaWASP 40100 Clay | ⌀ 400 x 1000 mm | Italy | $ 8,000 | Quote |

| 3DPOTTER | 3D PotterBot 10 XL | 490 × 490 × 710 mm | – | $ 8,580 | Quote |

| VormVrij | LUTUM 5 | 430 × 450 × 500 mm | Netherlands | $ 9,900 | Quote |

The products in the table are ranked by price (low to high).

| Product | Brand | Country | Build size | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| DeltaWASP 2040 Clay | WASP

Product data validated by the manufacturer.

| Italy | ⌀ 200 x 400 mm | $ 3,500 | Get a quote |

| 4.0 Multimaterial 3D printer | StoneFlower | Germany | 500 × 500 × 800 mm | $ 4,000 | Get a quote |

| LUTUM 4.5 | VormVrij | Netherlands | 430 × 450 × 500 mm | $ 6,000 | Get a quote |

| 3D PotterBot 10 Pro | 3DPOTTER | – | 415 × 405 × 500 mm | $ 6,105 | Get a quote |

| DeltaWASP 40100 Clay | WASP

Product data validated by the manufacturer.

| Italy | ⌀ 400 x 1000 mm | $ 8,000 | Get a quote |

| 3D PotterBot 10 XL | 3DPOTTER | – | 490 × 490 × 710 mm | $ 8,580 | Get a quote |

| LUTUM 5 | VormVrij | Netherlands | 430 × 450 × 500 mm | $ 9,900 | Get a quote |

Overview of the best clay 3D printers

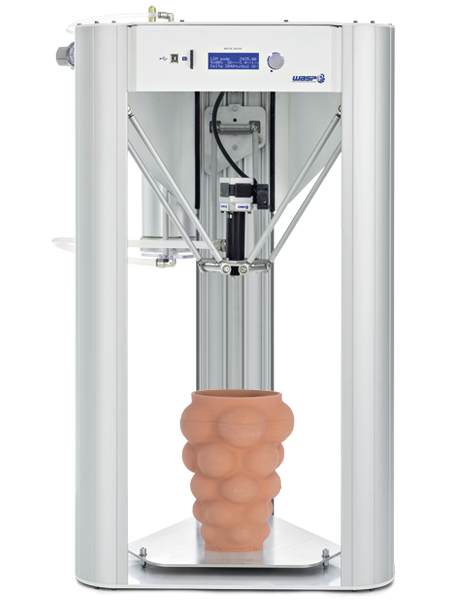

The Delta WASP 2040 Clay is the smaller of two delta-style clay 3D printers from Italian printer manufacturer WASP. Both printers require a separate air compressor for clay delivery.

The 2040 features an open design to allow for manual alterations during printing and is fitted with the LDM WASP extruder, capable of processing porcelain, earthenware, and other materials.

Other features include a Free Z-System for restarting interrupted prints at the correct height, and a Resurrection System for restarting prints interrupted by power failure.

The larger and more expensive of WASP’s clay printers, the Delta WASP 40100 Clay offers similar technical specs and features to the 2040.

Features unique to the 40100 include a baseless design which allows for printing directly onto external surfaces. This also allows the printer to be moved while the printed clay is still drying.

The machine can also be fitted with the LDM WASP Extruder XL, with nozzle diameters up to 8 mm.

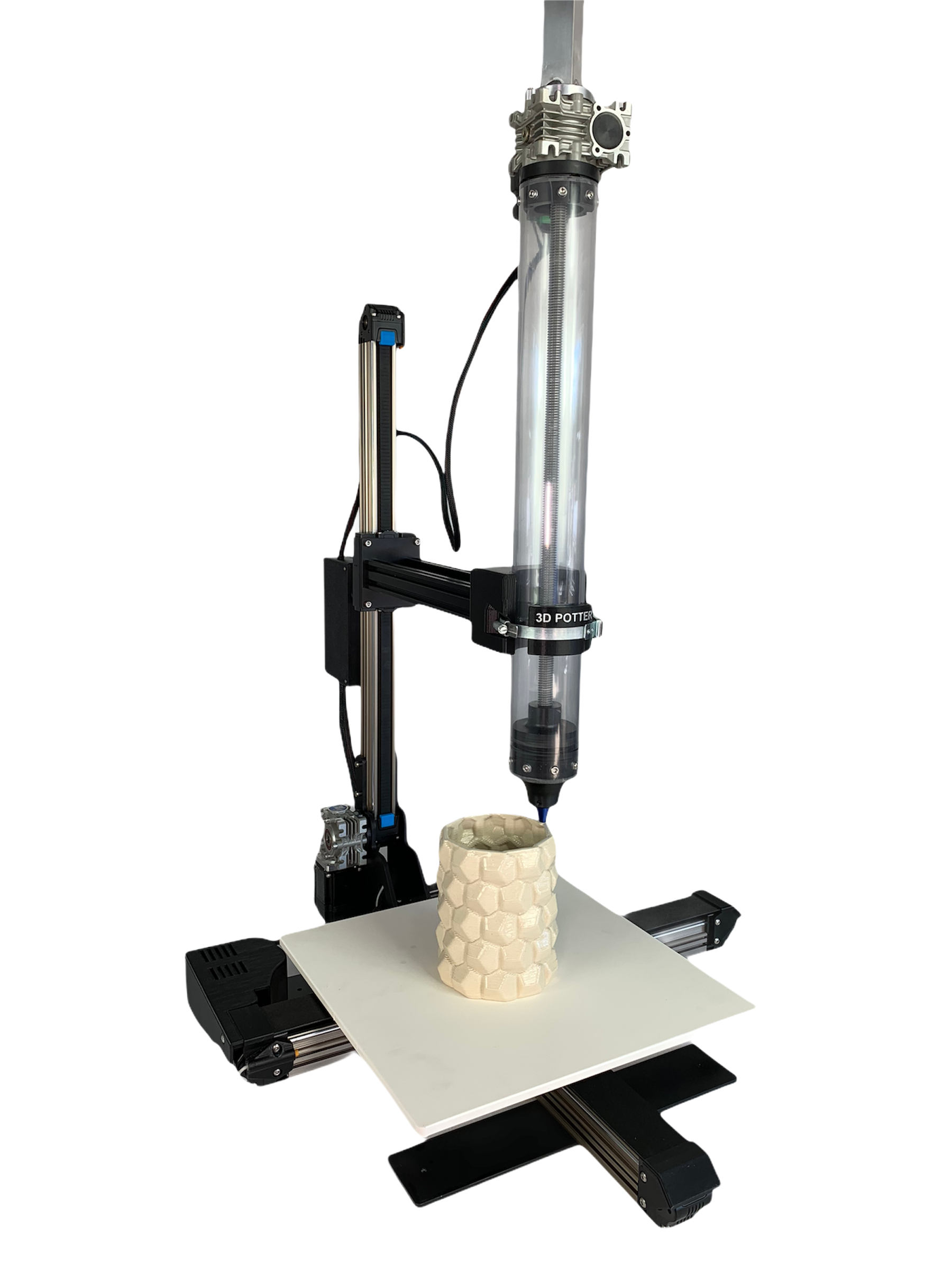

The 3D PotterBot 10 Pro is one of the most popular clay 3D printers from Florida-based printer developer 3D Potter. It is designed for researchers and artists.

The PotterBot 10 Pro is equipped with a stationary paste extruder which requires no external air compressor. This direct extrusion system allows for the use of undiluted clay.

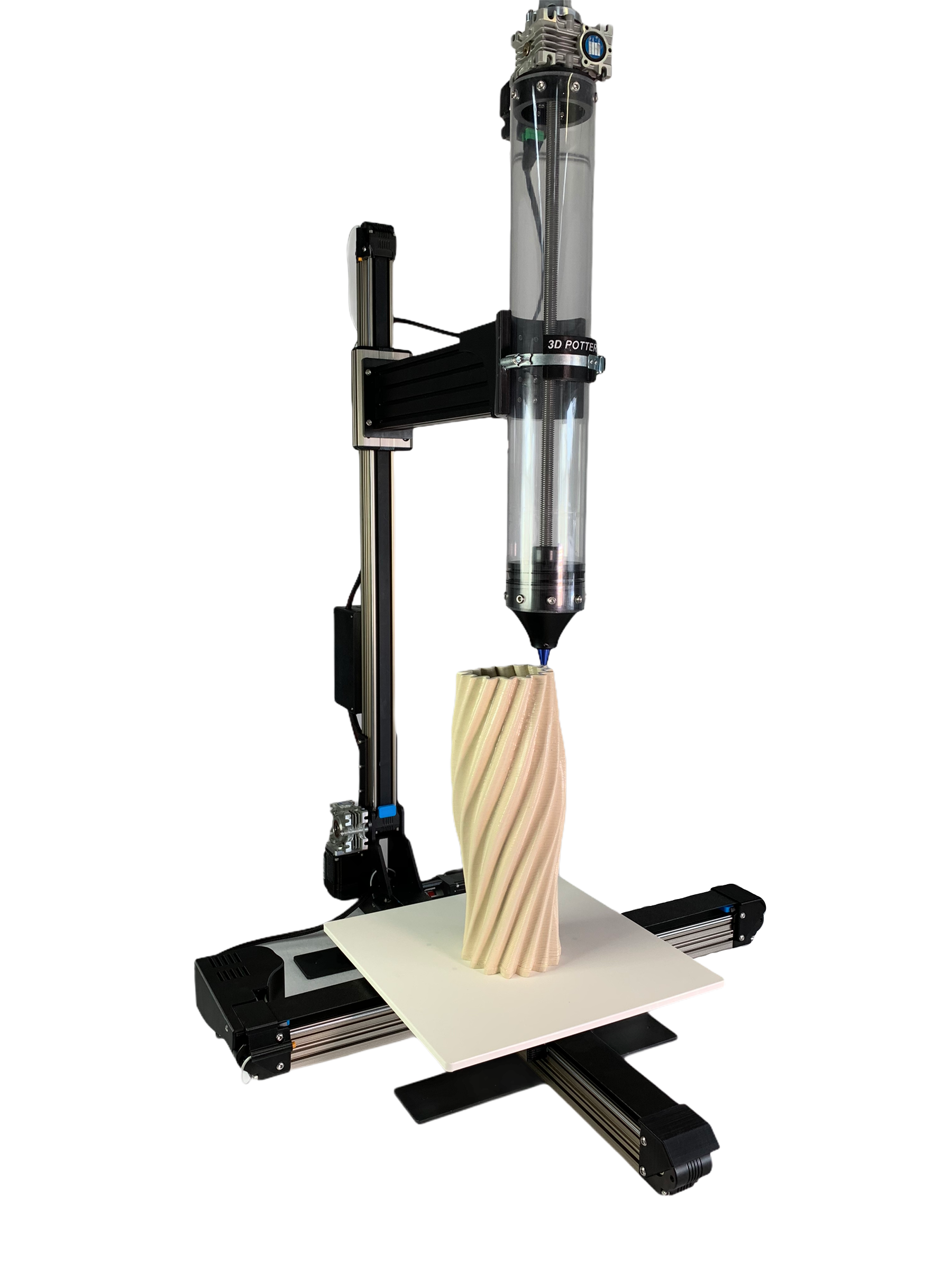

The PotterBot 10 XL is the largest cardinal rail printer in 3d Potter’s catalogue. It is more expensive than the PotterBot 9 but less expensive than PotterBot’s high-end Scara models.

The clay printer is available with a 3,600 ml or 4,000 ml extruder and, unlike the PotterBot 9, can print in reverse.

Like the 9 Pro, the 10XL syringe 3D printer uses a hybrid closed-loop stepper motor for all printing axes plus the extruder.

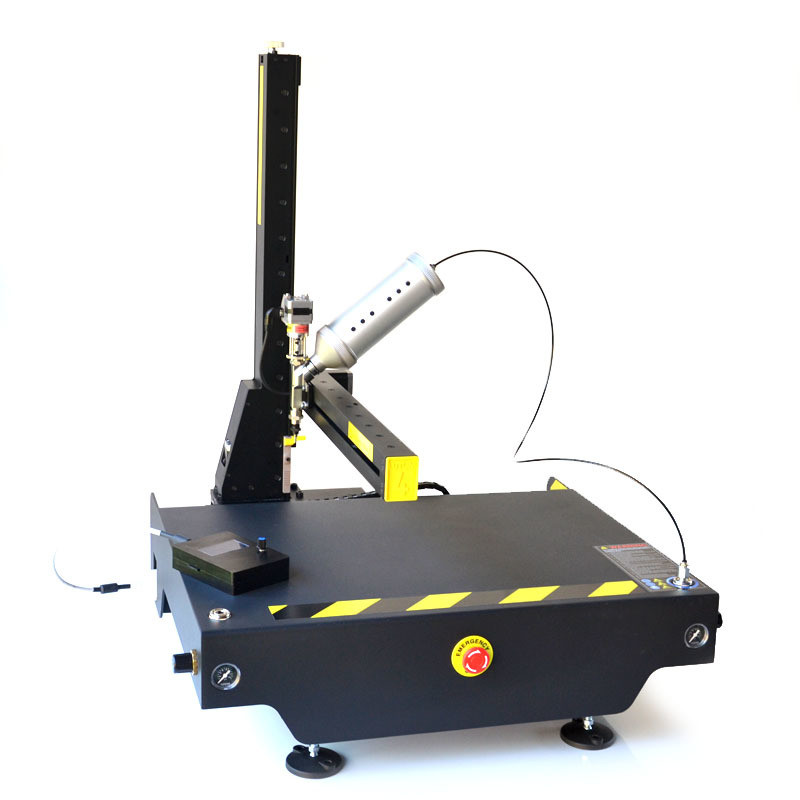

German company StoneFlower, founded by two researchers from the Technical University of Munich, sells clay printers, print heads, and printing kits.

The StoneFlower 3.1 is a cartesian-style printer with a ram extruder that can deposit materials like wet clay and porcelain. A second extruder can be fitted to the machine upon request.

Features include a 5” touch screen interface, bed level correction, and an emergency stop function.

The LUTUM 5 is a dedicated clay 3D printer from family company VormVrij, designed for ceramists, researchers, and educators. It is the most advanced model in the LUTUM line, distinct from the industrial-grade BRUTUM models.

The machine has a stainless steel worktop, heavy-duty linear rails, and a robust stainless steel extruder, making it suitable for long-session printing of clays with a range of viscosities. Features include a 7” touchscreen, auto bed leveling, and 32-bit electronics. An interesting feature to point out is that the print bed is stationary; only the print head moves, not the object being printed.

Like many comparable machines, LUTUM printers require a separate air compressor to deliver clay to the extruder. However, the clay cartridge is directly attached to the printer, eliminating flow latency.

Built for small ceramic studios, the LUTUM 4.5 is an affordable clay 3D printer from VormVrij.

The printer is available in a standard or PRO edition. The standard has regular printer guiding rails while the PRO has HIWIN rails and is suitable for universities, fab labs, and basic production.

Unlike the LUTUM 5, the LUTUM 4.5 clay 3D printer comes with a nylon extruder as standard. However, it can be upgraded to the stainless steel version. All LUTUM printers can accommodate a second extruder for more complex designs.

Special mentions

Hyrel 3D

Hyrel 3D is a 3D printer manufacturer that focuses on modularity. Its printers can accommodate a wide range of print heads and extruders to print different materials.

The EMO-25 is an anodized aluminum extruder compatible with various clays, including air-dry clays, metal clays, and porcelain. It can also process materials like plasticine, petroleum jelly, and RTV silicone.

WASP Clay Kit

In addition to its complete clay 3D printers, WASP sells a Clay Kit as a replacement/upgrade for its other printers, including those not tailored to clay printing.

The clay 3D printer DIY kit includes a three-liter tank and the LDM WASP extruder.

ZMorph Fab

The ZMorph Fab is a versatile, multifunctional 3D printer with interchangeable print heads, making it capable of processing a range of materials, from nylon to PC/ABS.

ZMorph’s Thick Paste Extruder can be fitted to the Fab for the printing of medium and dense masses like clay and cookie dough.

StoneFlower Ceramic 3D Printing KIT

Compatible with many standard FDM printers, the StoneFlower Ceramic 3D Printing KIT includes a print head (Auger extruder) and a powerful motorized syringe pump.

The syringe pump has a capacity of 500 ml and can process thick clay without the need for compressed air.

Cerambot

Chinese startup Cerambot raised $286,510 through a successful Kickstarter campaign in January 2019.

Its clay printer comes in two versions, one that requires compressed air and another that uses an integrated worm gear speed reducer to transport clay to the extruder.

The clay 3D printing process

The clay 3D printing process shares many characteristics with Fused Filament Fabrication (FFF), with some important differences.

As with FFF printing, the print head of a clay 3D printer moves according to computer instructions to deposit layer upon layer of material to create 3D shapes. However, clay — a natural soil material — is used instead of a heated thermoplastic.

Cartesian vs Delta style

Most clay 3D printers are cartesian or delta systems: print heads on cartesian printers move rigidly along the X, Y, and Z axes, while those on delta printers are pulled into position by three arms. Cartesian printers have square print beds, whereas delta printers generally have circular ones.

Material feed

The clay 3D printing process usually starts with the delivery of the clay substance to the extruder from a hopper, tank, or container. This can be achieved using compressed air or with a syringe or mechanical ram. Air compressors provide a constant source of fixed pressure, but mechanical rams can potentially move harder clay; both achieve the same end goal.

A demonstration of WASP’s clay 3D printing process:

Extrusion

Once the clay has been transported to the print head, it is extruded onto the print bed or onto the previous layer of clay. A clay 3D printer extruder works using compressed air and/or an auger (screw), which forces the clay out of the print head through a nozzle. Nozzles are often interchangeable to allow for different thicknesses of extruded clay.

Note that some printers, such as 3D Potter’s PotterBot machines, do not have a separate delivery and extrusion system; all of the clay is stored within the printer’s jumbo-size extruder, and a single source of pressure moves the entirety of the clay out through the nozzle.

Post-printing

After printing, the clay can be left to dry naturally or gently heated to accelerate the process. It is then fired in a kiln, which permanently hardens the clay object by fusing adjoining particles together. (As a rule, 3D printer manufacturers do not supply kilns with their printers.) If a glaze is required, it is usually applied after one round of firing and before another.

Types of 3D printable clay

Most clay 3D printer extruders can process a variety of clay and clay-like materials, which can be bought wet and ready to use or in the form of dry powder.

Manufacturers of clay 3D printers do not usually sell their own specially formulated printing clays. However, some materials are available from third-party developers. 3D Potter, for example, distributes a prepared 3D printable clay mix developed by international ceramics company Sio-2.

Almost all clays can be mixed so that they have the right consistency and viscosity for extrusion. Mixing involves diluting clays with water and/or adding grog (coarse, alumina-filled powder or chippings, also known as “chamotte”), which also helps to improve texture and prevent cracking.

How can you tell if your clay is printable?

Italian 3D printer company WASP says “the goal is to reach a mixture that is fluid enough to be able to come out from the small nozzles but at the same time hard enough to avoid collapse during printing.”

In other words, if you squeeze your clay mixture out of a small syringe, the extrusion should sag slightly; it should not remain perfectly straight (the clay is too hard) nor sag dramatically or collapse (too soft).

The ideal viscosity for a print also depends on factors like ambient room temperature, nozzle diameter, and desired printing speed.

Suitable 3D printing clay materials include:

- Stoneware

- Earthenware

- Porcelain

Clays can also be mixed with ceramic colorants prior to 3D printing in order to create colored items.

Applications for clay 3D printing

Pottery

The principal use of clay 3D printers is the creation of pottery. 3D printing allows ceramicists to digitally design items like jugs and vases and then accurately realize those designs through the 3D printer. Some potters may utilize a combination of 3D printing and manual techniques to make their pottery.

Even mass production is possible, as Vormvrij shows:

Art & sculpture

The field of pottery focuses on the creation of functional or partly functional vessels. However, it is also possible to use clay 3D printers to create purely aesthetic items like digitally designed sculptures. Many users of clay 3D printers create a mix of pottery and art, and the distinction between the two categories is often blurred.

In this video, Art Insider interviews Taekyeom Lee, a designer, and researcher that creates unique sculptures with his clay 3D printer:

Architecture

Clays with a relatively high grog content can be 3D printed to create architectural pieces like walls, statues, and grotesques. As part of an ongoing project called TECLA, Mario Cucinella Architects in Italy are currently using a large-scale WASP 3D printing system to create a two-room, dome-shaped building using local clay.

Research

Clay 3D printers are widely used in universities in a range of departments, from material science to architecture to art and design.

Clay or ceramic?

Clay 3D printing can be considered a subcategory of ceramic 3D printing.

Ceramic printing encompasses a broader range of additive manufacturing technologies beyond the extrusion of clay pastes. These technologies include binder jetting, photopolymerization, and powder sintering, which can be used to make high-value items like patient-specific medical implants.

Read our guide to ceramic 3D printing and 3D printers to learn more.

Clay 3D printer price

The price of clay 3D printers does not vary a huge amount since there are only a handful of manufacturers, most of which use broadly similar technologies.

In general, the average clay 3D printer cost is between $3,000 and $10,000.

Cheap clay 3D printers tend to have smaller build volumes and may not be able to extrude harder or coarser clays.

FAQ

In general, yes. When it comes to extrusion, the consistency and viscosity of the clay are more important than its origin or mineral composition. This just means you may have to dilute your clay or add a grog before it is printable.

If you have an open-architecture FFF 3D printer such as a RepRap, it may be possible to add clay printing functionality with an add-on like the StoneFlower Ceramic 3D printing KIT (note that some conversion kits are only compatible with printers made by the kit manufacturer).

3D printing opens up interesting new possibilities for clay forming, but its functionality is limited and it cannot replicate some manual techniques.

English

English  Français

Français