Strong, composite parts at your desktop with the Raise3D’s E2CF

Carbon fiber, a coveted 3D printing material

For the past couple of years, carbon fiber (CF) has been attracting much attention in the additive manufacturing industry. But what’s the deal?

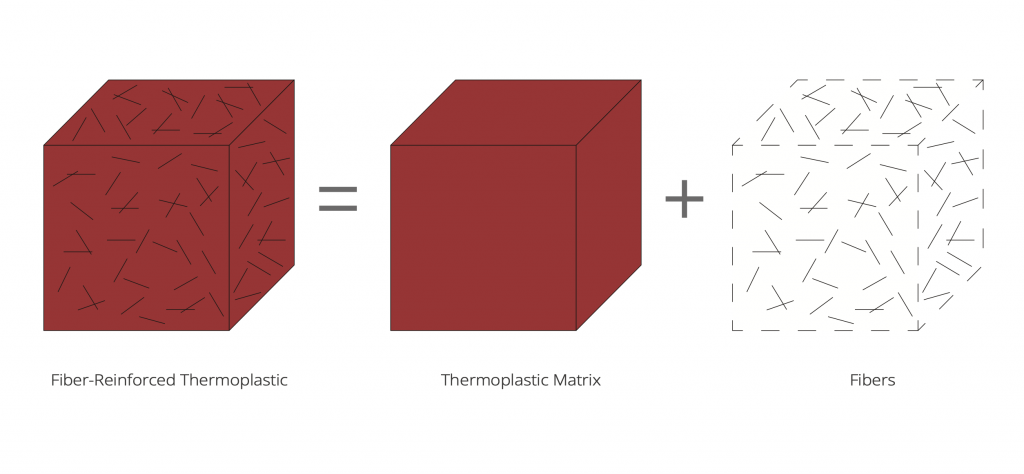

Carbon fiber, along with other fibers such as fiberglass or Kevlar, is a strong and stiff material that can be used to reinforce thermoplastics like polycarbonate or nylon. The end goal is to produce parts that are both stronger and more lightweight– i.e. with a high strength-to-weight ratio– whether you’re designing a part from scratch or seeking to replace a heavy and/or bulky metal part. This can be particularly useful, for example, in aerospace, automotive, or other industries where each gram counts; reducing an airplane’s weight can translate into huge economies of scale.

In FFF (Fused Filament Fabrication), fiber reinforcement can be done in two different ways. One method involves depositing a continuous strand of fiber during the 3D printing process, incorporating it into the part as it is being printed.

The other, which is Raise3D’s approach with the new E2CF and proprietary PA12 Carbon Fiber filament, consists of depositing thermoplastic filament that contains chopped bits of carbon fiber. Raise3D’s PA12 CF filament boasts fibers that are 20% to 30% longer than other carbon-fiber-filled filaments on the market, for superior strength and overall performance.

Download Raise3D’s Fiber-enforced Thermoplastic 3D Printing whitepaper for more information.

These filaments cannot be printed by just any 3D printer, however, as chopped fibers are highly abrasive and can damage any standard nozzle. A “carbon-fiber-ready” nozzle is required, like the E2CF’s hardened silicone carbide nozzle.

Enter the E2CF

The E2CF is built upon the award-winning E2 desktop 3D printer, known for its professional-grade results and ease of use. This new version was specifically designed to print composite fiber-filled materials and offer an even better user experience.

Raise3D E2CF overview

The E2CF is a 3D printer produced by Raise3D, a manufacturer based in the United States.

It uses the Fused Filament Fabrication technology to produce thermoplastics parts using filament feedstock.

It offers a build volume of 330 × 240 × 240 mm.

An extrusion system fit for the job

The E2CF features an enhanced, Dual Direct Drive Extrusion system to prevent the filament from slipping. It carries twice the feeding grip force as the E2’s system, with durable components (e.g. gears) that are tough enough to process fiber-filled materials with minimal wear.

The nozzles, made of silicon carbide, are also optimized for CF filament. According to Raise3D, they can withstand over 1,000 hours of printing with PA12 CF material.

IDEX for fast print times and complex support structures

The E2CF inherits the E2’s IDEX (independent dual extruder) and all its advantages. These two, independent extruders namely enable users to save time with Mirror and Duplication mode.

In Mirror mode, the print heads move opposite to one another while printing two parts: the original part, and an inverted version of that part (without having to create a second 3D file for the mirror part). Duplication mode basically doubles the printer’s production capacity by printing identical objects in pairs – both print heads move simultaneously and in the same direction.

IDEX systems also enable users to print with two different materials, and each print head can take its turn. Non-independent dual extruders are fixed right next to each other and the “paused” nozzles can interfere with the rest of the print job; but with IDEX, the idle nozzle is set aside while the second keeps moving. This mode is quite helpful in printing complex support structures.

Dry boxes for optimal material conditions

Raise3D’s boxes are equipped with suspension trays that allow the filament to be effortlessly and continuously rolled off the spool, whereas basic filament holders make the printer tug on the filament until the spool uncoils (often abruptly) the next few feet.

Raise3D’s filament dry boxes are also meant to prevent dust and moisture from getting to the filament and damaging it.

Safe for the office and user-friendly

As is the case with the entire Raise3D printer lineup, the E2CF series is safe for the office and user-friendly. Safety-wise, the E2CF features a power recovery system to resume prints after a power failure and sensors that enable the printer to pause jobs until all doors are closed. It’s also fitted with a HEPA filter to drastically reduce the number of particles and nano-particles released in the air during printing.

The E2CF displays a range of other professional-grade features that contribute to its smooth and enjoyable user experience:

- 7-inch color touchscreen

- Automatic bed leveling

- On-board camera

- Flexible build plate

- Easy Swap print heads

An efficient workflow

The Raise3D ecosystem also includes ideaMaker and RaiseCloud software solutions.

ideaMaker is Raise3D’s proprietary 3D slicing software, powered by smart algorithms and loaded with tools such as re-texturing and automatic support generation. It also easily lets users set varying parameters for different sections in a single model, and even includes basic modeling options to carve, split, and combine models.

Perhaps one of its most interesting features is the ideaMaker Library, where users can tap into preset material profiles and slicing templates to obtain the best possible results.

RaiseCloud can then be used to distribute print jobs to one or more 3D printers. This cloud 3D printer management software (available as a smartphone app, too) helps companies keep tabs on each printer, user, and print status, for efficient workflow management.

English

English  Français

Français