Carbon fiber 3D printers: 2024 guide to continuous fiber 3D printing

What is carbon fiber 3D printing?

In 3D printing, carbon fiber is increasingly used to reinforce other materials, usually thermoplastics. The key objective is to make parts stronger and lighter, coveted properties for numerous applications in a wide range of industries. In some cases, carbon fiber-enforced prints can even replace parts that are traditionally made of metal.

Two main methods exist to reinforce 3D parts with carbon fiber: using carbon-fiber-filled filaments or directly integrating a strand of fiber into each layer while it is being printed.

However, and this will be our primary focus here, continuous carbon fiber 3D printing provides much more strength and reinforcement possibilities. Engineers can choose the direction in which the part should be reinforced, resulting in strategically anisotropic parts, whereas chopped carbon fiber filaments boost strength in an isotropic manner.

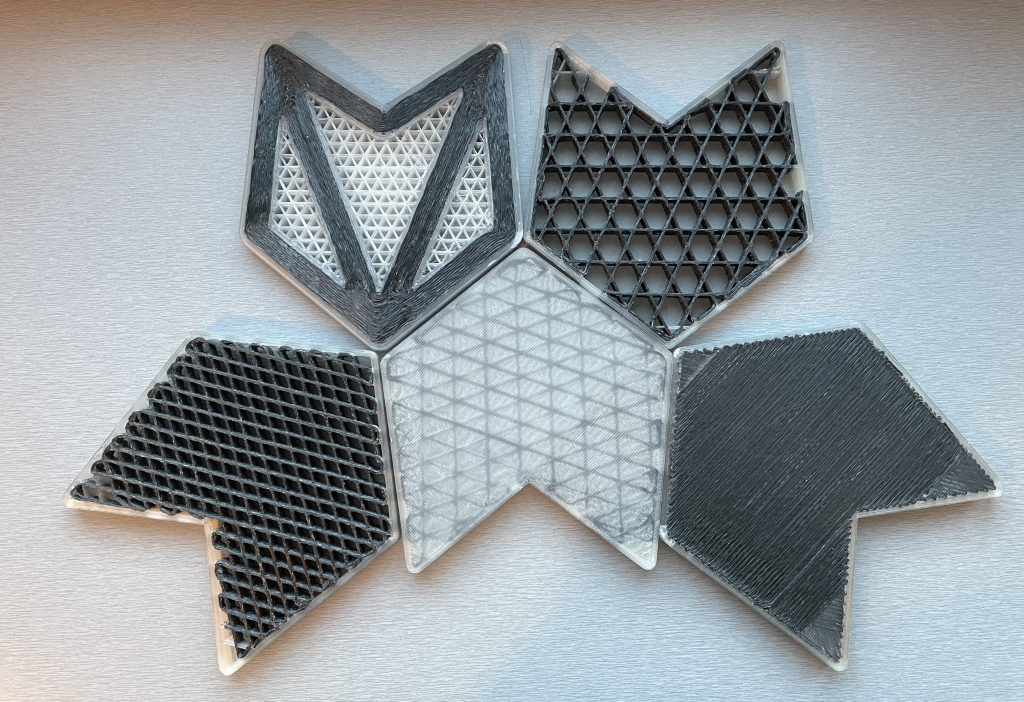

Here is an example of strategic carbon fiber reinforcement:

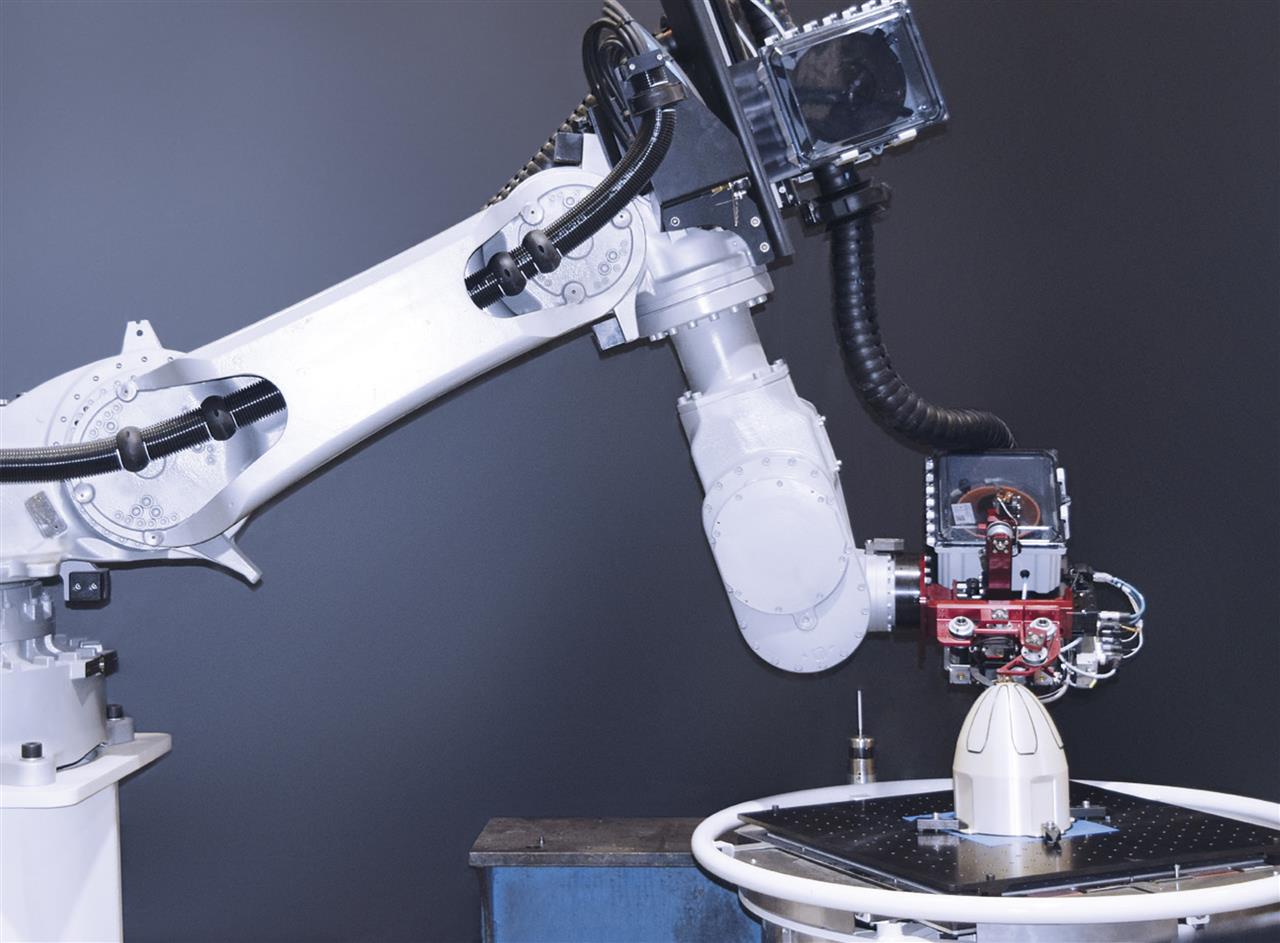

Within the continuous carbon fiber additive manufacturing market, however, the options can be quite diverse. You can find standard-looking desktop and benchtop 3D printers, enormous gantry-style systems, complex robotic arms, … and technologies that can range from extrusion to lamination and two-step processes requiring multiple machines.

Taking that into account, we split our selection into two lists to give a more meaningful, actionable overview of this market. On one hand, we grouped continuous CF 3D printers that can be considered office-friendly and/or off-the-shelf (to a minimum extent) solutions. Most of them cost less than $100K and are relatively easy to use.

On the other, we listed solutions with robotic arms (non-planar 3D printing) and/or large-scale footprints. They’re more complex to implement and they cost several hundred thousand dollars.

There will always be exceptions, overlaps, and different standpoints that could make one solution fall into one or the other– our split isn’t to be taken literally! But if you’re looking for a continuous carbon fiber 3D printing system, this article should help you get a good understanding and overview of the market.

Benchtop or “off-the-shelf” continuous carbon fiber 3D printers

The carbon fiber 3D printer list below includes solutions that are relatively turnkey. While some are borderline for this category, like the big Prom IS 500 or the two-step Red Series, they’re still much easier to implement and affordable than what our second list covers.

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Markforged

Product data validated by the manufacturer.

| Mark Two (Gen 2) | 320 × 132 × 154 mm | United States | $ 20,000 | Quote |

| Markforged

Product data validated by the manufacturer.

| X7 (Gen 2) | 330 × 270 × 200 mm | United States | $ 69,900 | Quote |

| 9T Labs

Product data validated by the manufacturer.

| Red Series | 350 × 270 × 250 mm | Switzerland | upon request | Quote |

| Desktop Metal | Fiber HT | 310 × 240 × 270 mm | United States | upon request | Quote |

| Massivit

Product data validated by the manufacturer.

| Massivit 10000 | 1420 × 1110 × 1500 mm | Israel | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Extruder temp. | Build plate temp. | Build chamber temp. | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|---|---|---|

| Markforged

Product data validated by the manufacturer.

| Mark Two (Gen 2) | 320 × 132 × 154 mm | – | – | – | United States | $ 20,000 | Get a quote |

| Markforged

Product data validated by the manufacturer.

| X7 (Gen 2) | 330 × 270 × 200 mm | – | – | – | United States | $ 69,900 | Get a quote |

| 9T Labs

Product data validated by the manufacturer.

| Red Series | 350 × 270 × 250 mm | – | – | 100°C | Switzerland | upon request | Get a quote |

| Desktop Metal | Fiber HT | 310 × 240 × 270 mm | – | – | – | United States | upon request | Get a quote |

| Massivit

Product data validated by the manufacturer.

| Massivit 10000 | 1420 × 1110 × 1500 mm | – | – | – | Israel | upon request | Get a quote |

Below, we give some more context and information about each of these continuous carbon fiber 3D printer options.

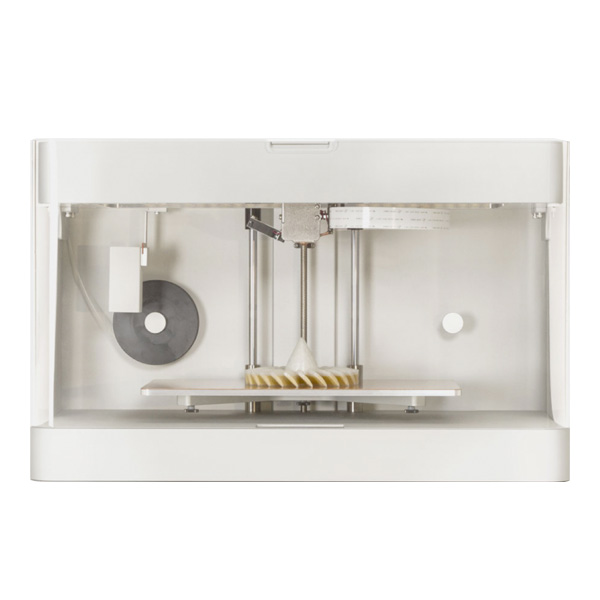

While the Markforged X7 is destined for industrial use, the Mark Two is a smaller, desktop carbon fiber 3D printer.

It’s compatible with a range of other fiber reinforcement materials, including fiberglass, Kevlar, and HSHT (High-Strength High-Temperature) fiberglass. As for base filament, it is only possible to use Markforged Onyx material.

The Mark Two’s print bed is easily removable, enabling users to pause a print, take the print bed out to add components to the part in progress, and to put the plate back into the machine to continue 3D printing.

If you’re looking for something more affordable, the Onyx Pro ($6,999) is available as well to reinforce Onyx chopped carbon fiber filament with a continuous strand of fiberglass.

The X7 prints Markforged’s proprietary Onyx filament– a strong Nylon that is already reinforced with chopped carbon fiber- and continuously reinforces it with a strand of carbon fiber. Hence, the printer delivers extremely strong parts. It is also very precise thanks to its built-in laser micrometer that constantly 3D scans the build area.

Their X series also includes the X3 for chopped carbon fiber filament, and the X5 for continuous fiberglass 3D printing.

9T Labs is a young innovative company focused on automated composites production based in Switzerland. Its two-step Red Series combines a classical FDM printing unit and an adjacent Fusion Unit for post-processing, both produced by 9T Labs.

The part is first printed on the “Build Module”, to then undergo high heat and pressure in the “Fusion Module” and achieve its final, condensed form.

Desktop Metal is mostly known for their disruptive metal 3D printers. Their Fiber series, which includes the Fiber LT and Fiber HT, however, tackles the continuous carbon fiber 3D printing niche.

Packed in a user-friendly system, their Micro AFM (μAFP or Micro Automated Fiber Placement) technology offers extremely strong and lightweight parts. The LT version allows you to reinforce PA6 (Nylon) with a continuous strand– or “tape” as called by Desktop Metal– of Carbon Fiber or Fiberglass.

Users that need to use more resistant materials should opt for the HT version, which is able to 3D print and reinforce high-performance polymers like PEEK.

Note: As of July 2022, this solution is not yet available for order.

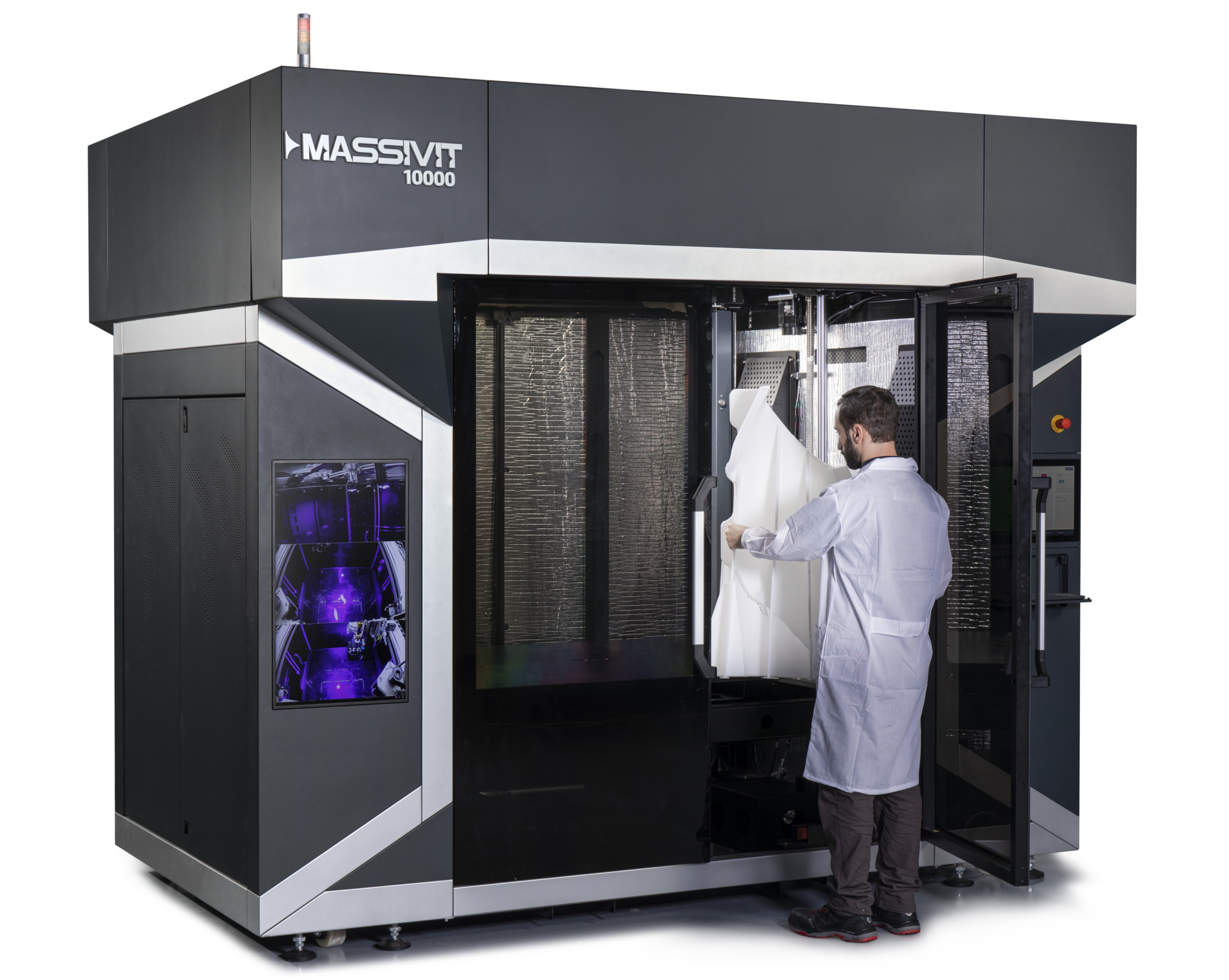

The Massivit 10000 additive manufacturing system is designed to overcome the bottlenecks of mold production for composite manufacturing. It enables fast, digital production of industrial-grade isotropic molds in 80% less time than with traditional tooling methods.

It offers a build volume of 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in.

Robotic arms and large-scale carbon fiber 3D printers

This section covers large-scale carbon fiber 3D printers and robotic-arm solutions for non-planar carbon fiber 3D printing.

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| CEAD

Product data validated by the manufacturer.

| Flexbot | 40000 × 4000 × 3000 mm | Netherlands | upon request | Quote |

| Continuous Composites | CF3D | – | United States | upon request | Quote |

| Impossible Objects | CBAM-2 | 305 × 305 × 102 mm | United States | upon request | Quote |

| Ingersoll | MasterPrint Continuous Filament | – | United States | upon request | Quote |

| Orbital Composites | Orbital S | 1000 × 1000 × 1000 mm | United States | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| CEAD

Product data validated by the manufacturer.

| Flexbot | 40000 × 4000 × 3000 mm | Netherlands | upon request | Get a quote |

| Continuous Composites | CF3D | – | United States | upon request | Get a quote |

| Impossible Objects | CBAM-2 | 305 × 305 × 102 mm | United States | upon request | Get a quote |

| Ingersoll | MasterPrint Continuous Filament | – | United States | upon request | Get a quote |

| Orbital Composites | Orbital S | 1000 × 1000 × 1000 mm | United States | upon request | Get a quote |

Below, we give some more context and information about each robotic arm carbon fiber 3D printer from our selection.

Orbital Composites Orbital S overview

The Orbital S is a 3D printer produced by Orbital Composites, a manufacturer based in the United States.

It uses the Continuous fiber deposition technology to produce continuous fiber reinforced polymers parts using filament feedstock.

It offers a build volume of 1000 × 1000 × 1000 mm.

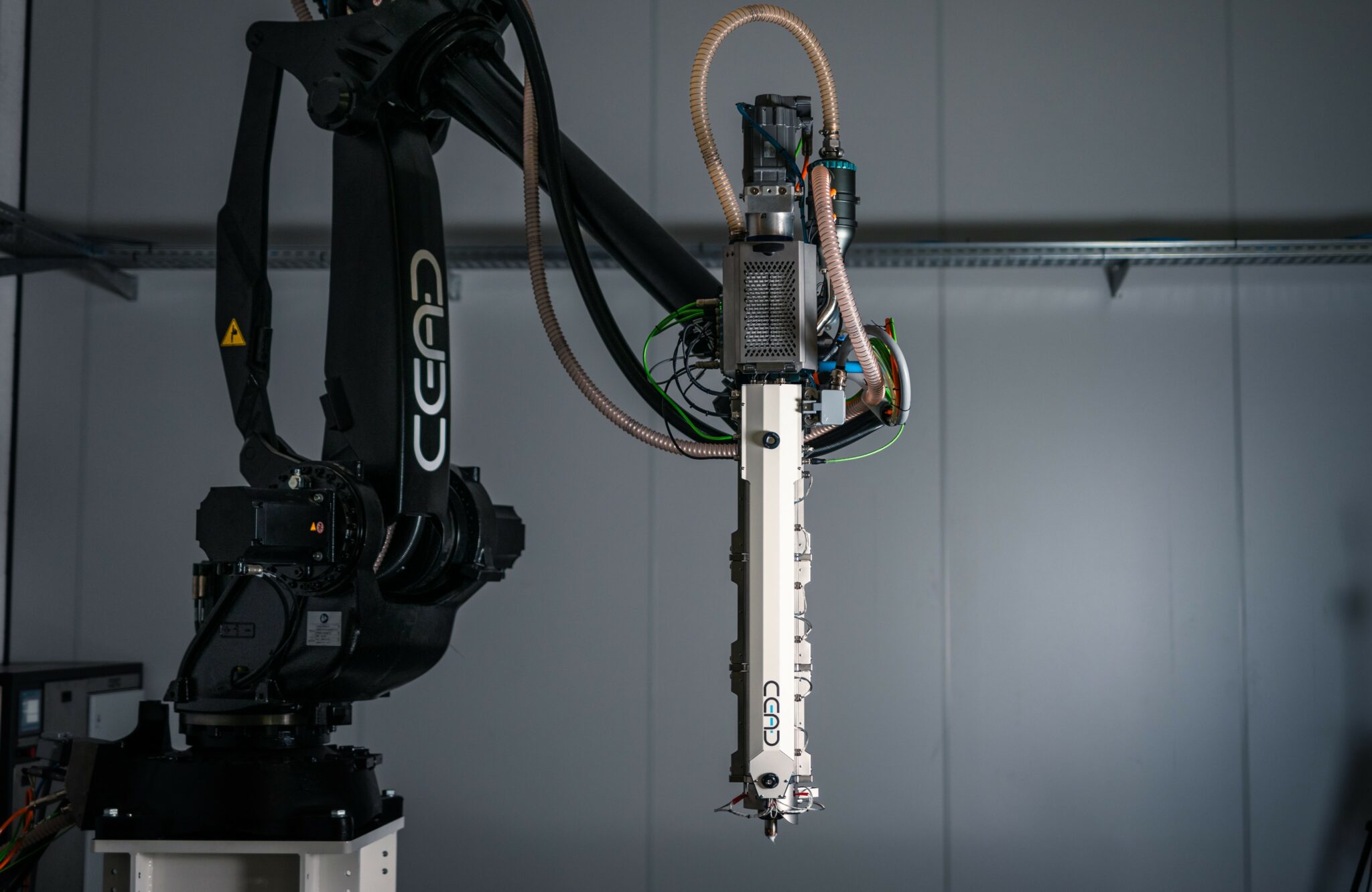

CEAD Flexbot overview

The Flexbot is a 3D printer produced by CEAD, a manufacturer based in the Netherlands.

It uses the Fused Granulate Fabrication technology to produce thermoplastics parts using pellet feedstock.

It offers a build volume of 40000 × 4000 × 3000 mm.

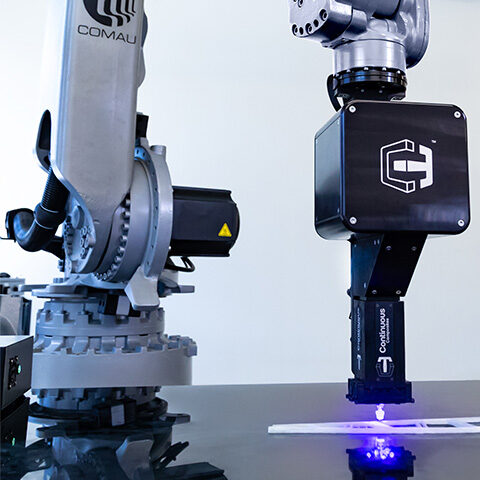

Continuous Composites CF3D overview

The CF3D is a 3D printer produced by Continuous Composites, a manufacturer based in the United States.

It uses the CF3D technology to produce continuous fiber reinforced polymers parts using liquid feedstock.

Impossible Objects CBAM-2 overview

The CBAM-2 is a 3D printer produced by Impossible Objects, a manufacturer based in the United States.

It uses the Composite-Based Additive Manufacturing technology to produce continuous fiber reinforced polymers parts using sheet feedstock.

It offers a build volume of 305 × 305 × 102 mm.

Ingersoll MasterPrint Continuous Filament overview

The MasterPrint Continuous Filament is a 3D printer produced by Ingersoll, a manufacturer based in the United States.

It uses the Fused Filament Fabrication and Continuous fiber deposition technologies to produce continuous fiber reinforced polymers and thermoplastics parts using filament feedstock.

Continuous fiber vs. chopped carbon fiber 3D printing

There is a big difference between printing with continuous fibers and printing with chopped carbon fiber filament.

Continuous fiber 3D printing

In this method, long, continuous strands of carbon fiber are mixed with thermoplastic base material during the 3D printing process. The base material, also called matrix material, can be PLA, ABS, Nylon, PETG, PEEK, or almost any other thermoplastic.

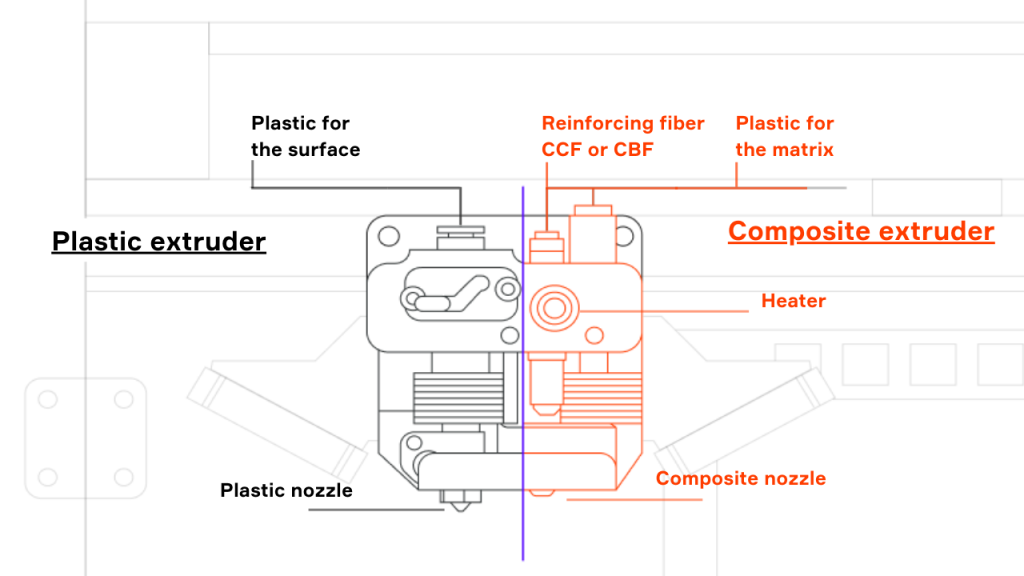

One way to reinforce parts with continuous carbon fiber is by using a dual extruder or two-in-one extruder, where a special nozzle deposits a single strand of fiber at the same time as the other nozzle heats and prints the base material. Markforged and Anisoprint use this kind of technology.

Continuous Composites, on the other hand, uses hybrid technology. Their system soaks a strand of fiber with resin, to then solidify it with UV light when it comes out of the nozzle. In other, simple words, it’s a mix of extrusion and photopolymerization.

9T Labs also uses a hybrid approach; the first module prints the composite part, and the second applies high heat and pressure to weld the layers together.

Chopped carbon fiber filament 3D printing

Chopped carbon fiber– or carbon-filled– filament, is the most common way to 3D print carbon fiber. Carbon fiber is already integrated into the filament and ready to print on a more or less standard FFF 3D printer.

A base material (again, PLA, Nylon, or other thermoplastics) is mixed with extremely small bits of carbon fiber. These small carbon fiber strands are abrasive, so the 3D printer will require a hardened steel nozzle or other tough nozzle to resist.

Parts printed with this type of filament are stronger than regular thermoplastic prints. That being said, the percentage of fiber used and the base thermoplastic (among other variables) determine how strong the final product is.

Other high-resistance composite materials for continuous fiber 3D printing

Various continuous fiber 3D printers are compatible with other types of fibers in addition to carbon.

Fiberglass 3D printing

This entry-level reinforcement material can produce parts that are considerably stronger and stiffer than ABS and Nylon. It is more flexible than carbon fiber and is less expensive.

Kevlar fiber 3D printing

Kevlar is another interesting fiber to 3D print with, especially when it comes to shock absorption.

Basalt fiber 3D printing

Basalt fiber parts can be as strong as stainless steel and five times lighter than steel.

Reinforcing parts with continuous carbon fiber

When using continuous fiber 3D printing with extrusion-type 3D printers, there are two different ways to reinforce parts.

- Outer layer or wall reinforcement (concentric)

- Inner infill reinforcement (isotropic)

It’s interesting and important to know what you’ll need for each part in order to optimize your carbon fiber stock.

In some cases, reinforcing only the perimeters of the part will be enough. Other applications may require a light carbon fiber infill, and others might need a very dense infill, which will be more expensive to print as it uses much more material.

3D printing carbon fiber composites: pros and cons

Like any material or technology, continuous carbon 3D printing has both advantages and limits.

Pros of continuous carbon fiber printing

Continuous carbon fiber 3D printing can produce parts that:

- Boast high strength, stiffness, and dimensional stability

- Are lightweight

- Have a great surface finish and appearance

It is also easy to work with and 3D print, and can be mixed with many different kinds of thermoplastic materials.

Cons of 3D printing parts with carbon fiber

The few disadvantages of carbon fiber include:

- Limited color choice (shades of dark grey)

- High price

This material is also brittle, but that can be compensated for when paired with a non-brittle plastic.

Carbon fiber 3D printing services

While printing with carbon fiber can produce amazing results, it’s not for everyone – especially if you don’t have the right machine. For businesses that only require a few parts per year, it may not be worth it to invest in a continuous carbon fiber 3D printer. If you’re interested in having something printed in carbon fiber or other materials, check out our guide to 3D printing services. You send them your 3D model, they print it with industrial-grade 3D printers, and ship the part to you.

FAQ

With the right nozzle and a heated bed, any standard FFF 3D printer can 3D print carbon fiber.

It is possible to 3D print fiberglass with a continuous fiber 3D printer.

Composite 3D printing is 3D printing materials that are a mix of two or more different materials. Some composite material examples include wood-filled PLA, carbon PEEK, and carbon PA.

English

English  Français

Français