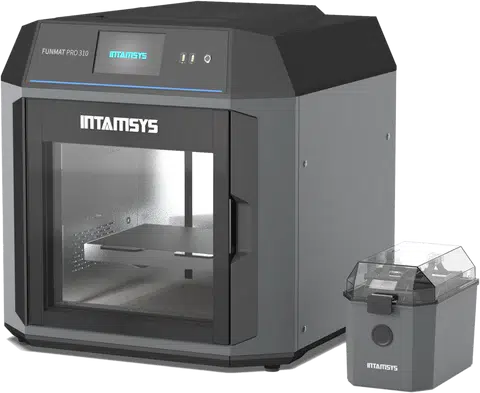

New INTAMSYS FUNMAT PRO 310: bringing industrial-grade performance to the desktop

FUNMAT PRO 310 overview

Industrial FFF 3D printer specialist INTAMSYS used Formnext 2022 in Frankfurt to launch its new desktop printer, the INTAMSYS FUNMAT PRO 310, a compact and affordable AM solution that brings to the desktop the industrial-grade features and performance from other systems in the FUNMAT PRO range.

INTAMSYS already offers three other 3D printers under the FUNMAT (Functional Materials) product line. Two of these, the FUNMAT PRO 410 and the newer FUNMAT PRO 610HT, are standalone industrial-size machines designed to print high-performance materials, with the 610HT offering an especially large build area. The other, the FUNMAT HT, is a desktop printer with a high-temperature nozzle, bed, and chamber, designed specifically for cost-effective printing of high-temperature materials like PEEK.

The new FUNMAT PRO 310 completes the existing INTAMSYS portfolio by introducing new features and applications. According to INTAMSYS, the printer is a response to the growing demand from professional engineers for higher-quality FFF printed parts while keeping within the compact desktop format.

Like other printers in the range, the FUNMAT PRO 310 works with several engineering materials suitable for a number of applications and allows engineers to focus on innovative research and development.

A large, enclosed build chamber

Although the FUNMAT PRO 310 is a more compact system than the PRO 410 and PRO 610HT, the new desktop 3D printer retains a large build area of 305 x 260 x 260 mm, larger than a typical desktop FFF machine (around 200 x 200 x 200 mm).

But it takes more than just a large build volume to print full-size industrial parts. For most desktop-level 3D printers — even ones with a big envelope — it is a challenge to print large parts. Warpage, delamination, and cracking often occur, resulting in printing failure. If printed material cools down too quickly after extrusion, it will cause internal stress when the material is solidified, resulting in poor interlayer bonding. A heated bed can go some way to mitigating this issue, but it is often not enough.

The solution is a closed, thermostatic chamber that provides an even amount of heat throughout the build area. Like the other machines in the FUNMAT range, the FUNMAT PRO 310 delivers in this regard, offering sealed thermal insulation that reduces heat loss. The thermostatic chamber can reach a stable temperature of up to 100°C, which is higher than the PRO 410 and FUNMAT HT whose build chamber can reach 90°C, but lower than the PRO 610 which can go up to 300°C. The constant high temperature maintained in the enclosed build chamber ensures the viability of large-scale industrial parts made from high-strength engineering materials like ASA, PC-ABS, and PA-CF.

Hardware and features

The FUNMAT PRO 310 contains a few standout features, some of which can also be found on the other FUNMAT PRO models and some of which are unique to it.

Sealed filament box

Combined with the reusable molecular sieve, the sealed drying filament box keeps humidity levels low to prevent issues like holes or stringing — particularly important when printing with hygroscopic materials like nylon. Unlike the filament chambers on the 410 and 610HT models, the 310’s drying box is independent and can be stored separately.

Independent Dual Extruders (IDEX)

The plug & play and easy-to-remove modular IDEX design of the PRO 310 supports multiple printing modes such as support mode, dual material mode, mirror mode, and duplicate mode. INTAMSYS sells its own build and support materials, but the printer — like others in the FUNMAT range — uses an open materials system compatible with third-party materials.

Robust frame

The high-rigidity metal frame of the INTAMSYS PRO 310 keeps vibrations to a minimum during printing and works with the motion control system to achieve continuous and stable printing.

Smart software

The process control software can meet various application requirements via intelligent path planning, taking into account material and part function to improve the printing success rate.

User-friendly INTAMTOUCH interface

The FUNMAT PRO 310 has a 7-inch full-color touchscreen with an overhauled interface, making it the most user-friendly printer in the FUNMAT range. Features of the INTAMTOUCH interface include:

- Intelligent multi-point mesh leveling without manual calibration

- Real-time compensation for motion accuracy

- Automatic queue management

- Standard API interfaces

- Seamless integration with MES

- Network printing function with visual monitoring, traceability of production data, and online diagnosis and maintenance

Materials and applications

The introduction of the FUNMAT PRO 310 opens up the printing of functional materials to new users in aerospace, automotive, electronic manufacturing, consumer goods, healthcare, research, and other industries. The FUNMAT range (including the two high-temperature printers) allows the printing of materials ranging from high-performance materials (PEEK, PEKK, PEI 9085, PEI 1010, PPSU) to engineering plastics (PA6-CF, PA12-CF, PA6/66, PC, ASA).

The FUNMAT PRO 310 is a professional industrial grade high-performance 3D printer produced by INTAMSYS. INTAMSYS is a 3D printer manufacturer based in China. The INTAMSYS FUNMAT PRO 310 uses extrusion 3D printing technology.

INTAMSYS specializes in high-temperature 3D printers for high-performance materials. These engineering materials include PEEK, PEKK, PC, and PEI (among others). With whole process control, the FUNMAT PRO 310 offers engineering material capabilities such as ASA, ABS, PC, PC-ABS, PA and PA-CF with INTAMSYS user-friendly 3D model-slicing software, INTAMSUITE. INTAMSYS 3D printers are all open material systems either welcoming INTAM™ filaments (which come with ready-to-print settings) or filaments from third-party manufacturers.

Bring industrial performance to your desktop/Industrial 3d printing performance accessible.

Debuted at Formnext 2022, the FUNMAT PRO 310 is currently available for pre-order and is expected to be made widely available by mid-2023.

Parts gallery

English

English  Français

Français