Compare

ExAM 255

| Technology | Material Extrusion |

| Materials | Ceramic, Metal, Polymers |

| Feedstock format | Pellet |

| Build envelope | 255 × 255 × 255 mm |

| Country | Germany |

Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ...).

upon request

Description

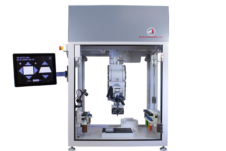

AIM3D ExAM 255 overview

The ExAM 255 is a 3D printer produced by AIM3D, a manufacturer based in Germany.

It uses the Fused Filament Fabrication, Fused Granulate Fabrication and Paste deposition technologies to produce ceramics, steel and thermoplastics parts using pellet feedstock.

It offers a build volume of 255 × 255 × 255 mm.

AIM3D ExAM 255 price

Please contact us to get a quote.

Technical specifications

General |

|

|---|---|

| Model | ExAM 255 |

| Brand | AIM3D |

| Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ...). | upon request |

| Country | Germany |

| Status | Available |

| Release date | 2017 |

| Topics | Pellets |

| Certifications | - |

Performance |

|

|---|---|

| Build envelope | 255 × 255 × 255 mm |

| Build volume | 16.58 L |

| Max. resolution (XY) | 0.05 mm |

| Max. resolution (Z) | 0.02 mm |

| Max. build rate | - |

| Max. chamber temp. | - |

| Full color | - |

Technology |

|

|---|---|

| Process | Material Extrusion (MEX) |

| Technology | Thermally-bonded > Fused Filament Fabrication (FFF) |

| Technology | Thermally-bonded > Fused Granulate Fabrication (FGF) |

| Technology | Chemically-bonded > Paste deposition |

| Max. print speed | 225 mm/s |

| Max. deposition rate | - |

| Filament diameter(s) | - |

| Max. build plate temp. | - |

| Number of extruders | - |

| Max. extruder temp. | - |

| Independent Dual Extruder (IDEX) | - |

| Nozzle diameter(s) | - |

Materials |

|

|---|---|

| Feedstock format | Pellet |

| Materials | Ceramic |

| Ceramics (others) | |

| Metal | |

| Steel | |

| Stainless steel | |

| Polymers | |

| Thermoplastics | |

| PLA | |

| Polyamides | |

| Polycarbonates | |

| Polyesters | |

| Styrenes: ABS, ASA | |

Applications |

|

|---|---|

| Industries | - |

Hardware |

|

|---|---|

| Dimensions | - |

| Weight | - |

| Axes | - |

| Hybrid manufacturing | - |

| Robotic arm | - |

English

English  Français

Français