A look at PostProcess Technologies’ 2nd Annual Trends Report

Are you in on the “dirty little secret” of additive manufacturing (AM)?

As the AM industry continues to expand, it is now widely recognizing the post-print step, also known as post-processing, as a critical element in the path to high-volume production scaling.

While 3D printers allow manufacturers to design and print parts at speeds and in geometries never before achievable, archaic post-printing methods like spraying or hand sanding perpetually lead to bottlenecks within otherwise streamlined additive workflows.

PostProcess Technologies, a pioneer of technologies in the automated post-printing segment of the market, recently issued an industry-wide survey and comprehensive report of trends in the additive post-printing market.

After surveying hundreds of companies across the additive sector, the survey results are launched in the 2nd Annual Additive Post-Printing Trends Report, the second iteration of the only existing report on additive post-printing.

This 2020 report delves into key trends and statistics regarding post-printing challenges, growth plans, and more.

PostProcess took steps to ensure the data was aggregated from qualified respondents. Those who were not familiar at all with AM, as well as those who had all of their AM outsourced, were filtered out.

With over 95% of the survey base self-identifying as moderately to extremely familiar with AM post-printing methods, it is assured that the data comes from reliable sources. Across the board, the respondents represent more than ten different industries and a variety of applications.

Highlights by Print Technology

While there are a variety of 3D print technologies on the market, the top four technologies reported to be in use account for 84% of all survey responses, and include:

- Material Jetting (MFM, MJP, SCP, PolyJet),

- Powder Bed Fusion (LS, SLS, DMLS, EBM),

- Vat Photopolymerization (SLA, DLP, CLIP),

- and Material Extrusion (FDM, FFF, MEM).

Though the length of time spent to finish parts was reported as the top pain point across all four technologies, the individual analysis of each reveals unique opportunities to help relieve the post-print bottleneck.

Those printing via Material Extrusion indicated having the most difficulty with damaged parts. Meanwhile, Powder Bed Fusion and Vat Photopolymerization users report the most issues with over-dependence on skilled labor for post-printing.

These concerns are especially critical, considering these two printing technologies are nearest to production scale adoption, and labor-intensive post-printing operations are not sustainable for higher volumes.

Vat Photopolymerization respondents also cited having the highest concern for improving the health/safety/environmental aspects of their post-printing operation, followed closely by Powder Bed Fusion respondents, as these methods tend to rely the most heavily on chemicals and manual labor during post-printing.

Highlights by Market

As was previously stated, survey respondents came from ten different industries, but those from automotive, aerospace, and defense markets report that their current post-print methods are already a challenge to meeting their additive manufacturing goals. Considering these markets have some of the highest projections for growth, it is imperative for these challenges to be addressed.

While improving end part quality was cited as the #1 priority for most markets, this was most dramatically the case for medical users, 93% of whom indicated it being a primary consideration.

When participants were asked what percentage of their additive expenditures were allocated to post-printing, those in the automotive field selected the “+51% category” at about two times that of any other market.

For reference, the majority of respondents selected the “10-25%” range. This may be because the automotive market is one that is near higher volumes, and a lack of utilization of automation during post-printing can drive costs higher.

Looking to the Future

In this year’s report, 75% of respondents across several markets reported performing 3 or more post-printing methods, versus only 50% last year. That equivocates to the need for more skill sets, software, and equipment, which only complicates workflows.

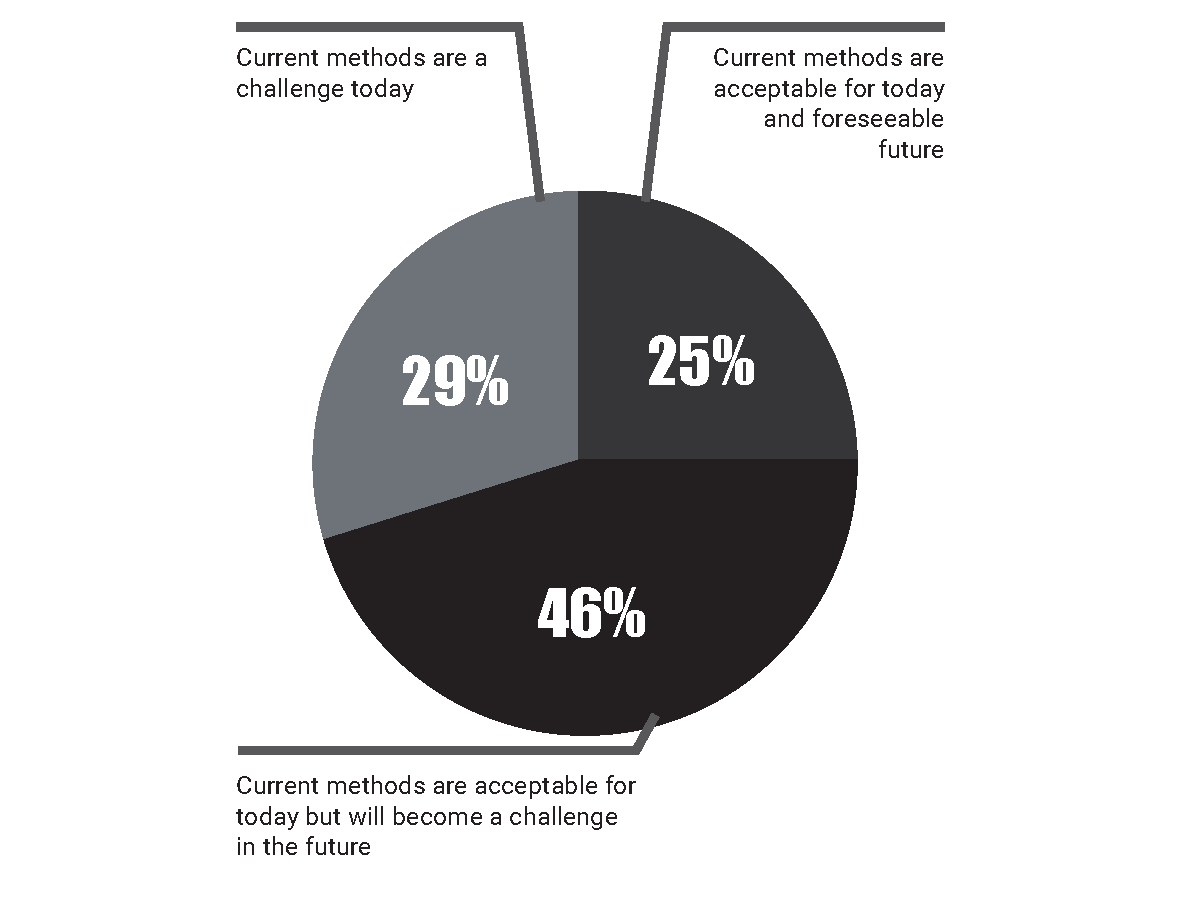

As more companies embrace numerous print technologies, the need for a streamlined post-printing operation becomes more imperative. When this year’s respondents were also asked to reflect on their future plans, only 25% say today’s methods are acceptable for what they have planned for their additive operations.

These results prove the magnitude of the toll that post-printing methods can take on additive efficiencies and highlight the necessity of an automated post-printing solution.

Download the report in full to explore further: https://www.postprocess.com/trends-2020/

English

English  Français

Français