GOM ATOS Q review: a powerful semi-automated metrology solution

Introduction

German company GOM has been developing 3D measurement technology since 1990 and was recently acquired by ZEISS Group, another leading optical equipment manufacturer. GOM specializes in industrial 3D coordinate measuring technology, 3D computed tomography, and 3D testing.

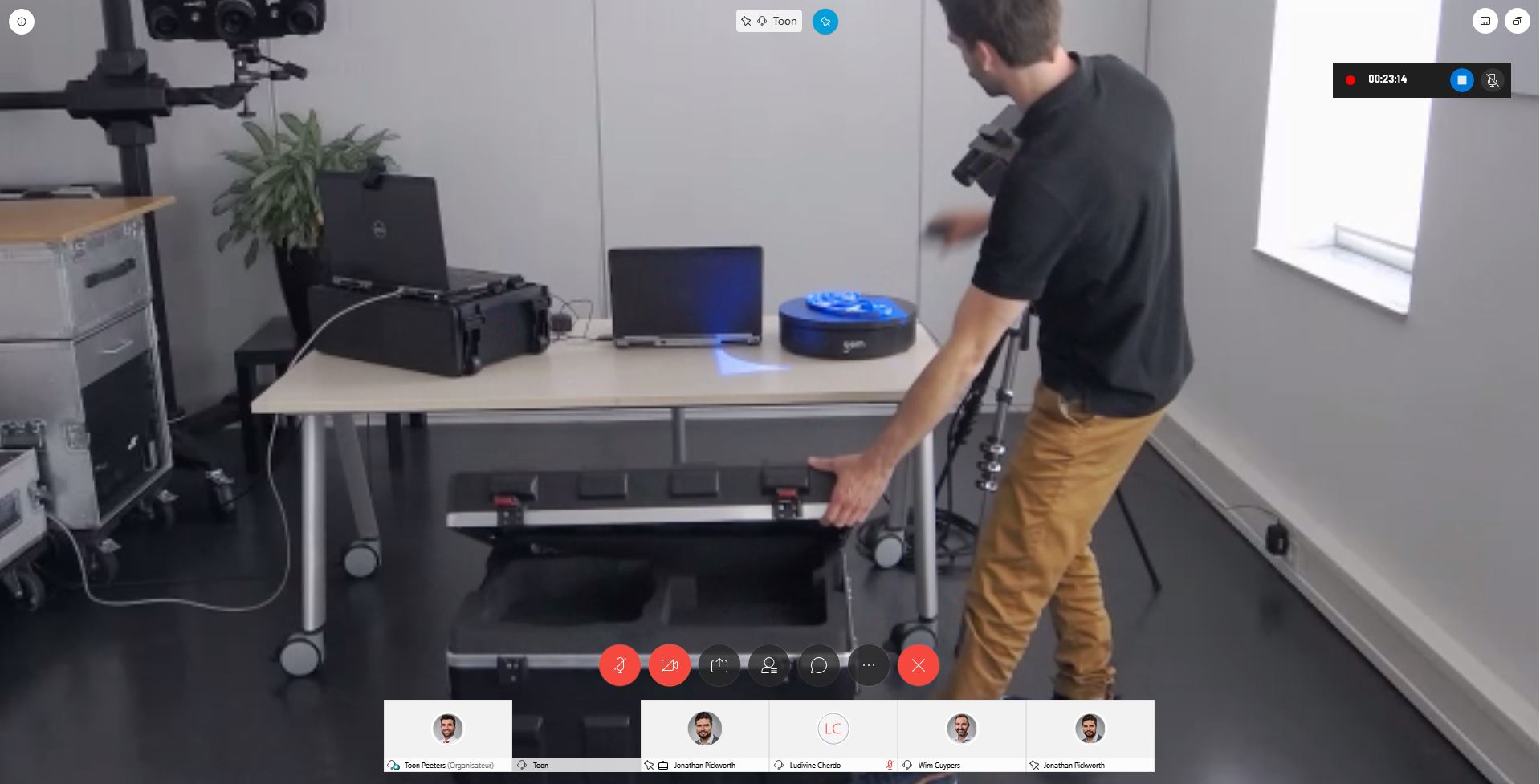

Mid-May, amidst the worldwide confinement situation, we virtually tested their GOM ATOS Q system via Webex. While physical handling is often preferable, the virtual setup did enable more people to take part in the review: two of us from Aniwaa (myself and Ludivine), and three on GOM’s side.

| Country | Germany |

| Technology | Structured light |

| Price | upon request |

GOM ATOS Q overview

The ATOS Q is a 3D scanner produced by GOM, a manufacturer based in Germany.

The ATOS Q GOM uses the structured light technology.

Toon Peters carried out the demonstration with support from two experts, Jonathan Pickworth and Wim Cuypers, for complementary insights regarding their technology and appropriate use cases.

The ATOS Q is GOM’s latest addition to the ATOS family, a lineup of industrial-grade optical metrology solutions. These non-contact solutions include the ATOS 5 series (5, 5X, 5 for Airfoil) as well as the ATOS Triple Scan, Capsule, Compact Scan, and Core systems.

Where does the ATOS Q sit within GOM’s lineup?

The ATOS Q is aimed at industrial users looking for a powerful and flexible metrology solution at a reasonable price. It reaps all of the ATOS family’s benefits in terms of speed, accuracy, and ease of use while being more transportable and affordable. The ATOS Q is, for example, twice as small as the flagship ATOS 5, and half its price.

This metrology 3D scanner exists in two different versions, ATOS Q 8M and ATOS Q 12M, the numbers designating the number of points per scan (see table below). Both versions come with 3 different lenses, each suited for varying measuring volumes, and boast VDI 2634 compliance.

| Points per scan | Point-to-point distance (resolution) | |

| ATOS Q 8M | 8 million | 0.04 – 0.15 mm |

| ATOS Q 12M | 12 million | 0.03 – 0.12 mm |

Toon demoed the higher-end 12M version for us, though we will simply refer to it as the ATOS Q throughout this review.

Pros

Pros

- Transportable and dust-free

- Specifically tailored for industrial metrology applications

- Five different scanning volumes

- Acquisition speed

- Automation possibilities

Cons

Cons

- Expensive

- Large transport case

Packaging

As you can see in the picture below, the ATOS Q 3D scanner and its accessories all fit inside a special case. The separate case on the table is for the included laptop and can serve as a stand, which is convenient out on the field (e.g. factory floor, assembly line).

Although the ATOS Q is easier to transport and set up than the ATOS 5, further up the product line, it is still a bit of a hassle. The case is large and heavy, equipped with wheels to help users move it around, and the PC and its case also have to be taken into account.

That being said, it is certainly not to the scanner’s disadvantage when compared to bulky CMMs (coordinate measurement machines) and other metrology tools that are far from being as easy to use, pack up, and transport. Gradually replacing that kind of cumbersome equipment is the point, after all.

In addition to the scanner itself, the transport case contains:

- A tripod

- An automatic turntable

- Three sets of lenses (intended for 5 different measuring volumes)

- One small calibration panel protected by a wooden case

- One big calibration plate for large-volume 3D scans

- Power and connectivity cables

PC requirements

3D scanning software is always very demanding for computers. That’s why the ATOS Q is automatically bundled with a powerful Windows 10 64-bit laptop, pre-loaded with the latest version of GOM Inspect software.

Since GOM Inspect can be downloaded and used for free, GOM also indicates the minimum and recommended computer configurations for reference.

Minimum configuration:

- CPU: Intel Core i3

- RAM: 4 GB

- OpenGL-compatible graphics board

- Windows 7 SP 1 64 Bit with latest security updates

Recommended configuration:

- CPU: Intel Core i7 (QuadCore)

- RAM: 16 GB

- Windows 10 64 Bit with latest security updates

We did not experience any issues with the software during the two-hour-long demonstration, even while Toon was simultaneously sharing his screen.

Overview and setup

Toon’s installation enabled us to have a full view of the scanner, laptop, and software. One laptop was used for webcam streaming, while the other was used for 3D scanning and screen sharing.

During the review, the ATOS Q was set up in a stationary configuration on the included tripod and offered semi-automated scans with its rotating table.

The ATOS Q can also be fully automated when paired with a GOM ScanBox or robotic arm.

Software

GOM Inspect, the proprietary software suite with which the ATOS Q works, plays a key role in the quality and performance delivered by the scanner. This software is comprehensive and sweeps (or plows) through the entire metrology process, from data acquisition, processing, and editing to full data quality inspection and customized report generation.

A basic version is available for free and already offers a great deal of power and functionalities, including full inspections and reports, part-to-CAD alignments, and mesh editing.

The paid version, dubbed GOM Inspect Professional, includes more advanced options and additional capabilities. One of its main advantages compared to the free version is its full, drag-drop-recalculate process. This enables identical parts to be inspected one after the other without having to reset inspection parameters.

GOM Inspect features a clean and intuitive interface, with an extensive amount of possibilities and settings that are well-organized within various menus. Even though it takes a bit of exploring to fully grasp the software’s capacities, anyone used to dealing with 3D software will quickly find their way around.

Hardware

The first thing we noticed is the ATOS Q’s industrial look, conveying metrology as its true purpose, and not simply 3D scanning. It’s equipped with two cameras, which are covered when idle to protect them from dust, and one light projector.

Two eye-safe lasers are also there to help users aim the scanner correctly. If you’re too far or too close, the lasers let you know. By default, this visual aid system is deactivated, but it can be activated for manual scanning modes.

The ATOS Q comes with three sets of lenses to obtain 5 different measuring volumes (area that can be captured in a single scan, which takes a second or so). These volumes range from 100mm to 500mm, and it is very easy to pull several 3D scans together to obtain a larger measured volume.

It is usually recommended to limit the object’s size to two and a half times your measuring volume in order to keep the same scanning accuracy. If you want to capture something bigger, like a car, you will need to use an add-on photogrammetry system.

Technology

Like the rest of the ATOS family, the Q uses blue structured light technology, casting fringes– a set of vertical lines– onto the part being measured. This projected LED light is captured by the scanner’s two high-speed cameras.

During the demonstration, Toon and his colleagues emphasized on GOM’s Triple Scan Principle.

Put more or less simply, it means that the scanner collects three sets of data for each scan: two sets from the cameras, and one from the projection unit, since the latter is programmable and thus calibratable (versus older or cheaper scanners which use “slides” of patterns).

This offers the ability to scan deeper into pockets or holes, a tremendous advantage for complex geometries.

Another noticeable difference with other, cheaper 3D scanners on the market is that the ATOS Q is equipped with a blue light equalizer. Indeed, most projectors have a natural vignette behavior.

This can best be illustrated with Toon’s flashlight example: usually, the light is brightest at the middle, and becomes “fuzzy” or weak at the edges. Thanks to its equalizer, the GOM ATOS Q’s blue light is equally intense and speckle-free over the whole measuring volume.

Unwavering, uniform light intensity is very important for reflective/shiny surface acquisition.

Getting started

To get started with the ATOS Q, you first need to equip the sensor with the right set of lenses for the particular part you are scanning.

Once the sensor (scanner) is mounted on its tripod, you can direct it towards the part. The two visual aid lasers help you position the tripod at the right distance and angle.

To perform a full metrological acquisition of a part, it is faster and more convenient to use the included automatic turntable, which you can operate directly via GOM Inspect software. This enables the scanner to efficiently capture the object from all 360° angles.

For the demonstration, both the turntable and the part were equipped with adhesive markers. Marker placement isn’t mandatory, but it does offer added accuracy and real-time calibration verification.

The markers can be applied to the measurement table or fixture, instead of users having to stick and unstick them from each scanned part.

Once the ATOS Q is firmly attached to the tripod and properly positioned towards the part, it must be connected to the laptop with its 10-meter fiber-optic cable.

Experience

Software

Acquisition and mesh generation

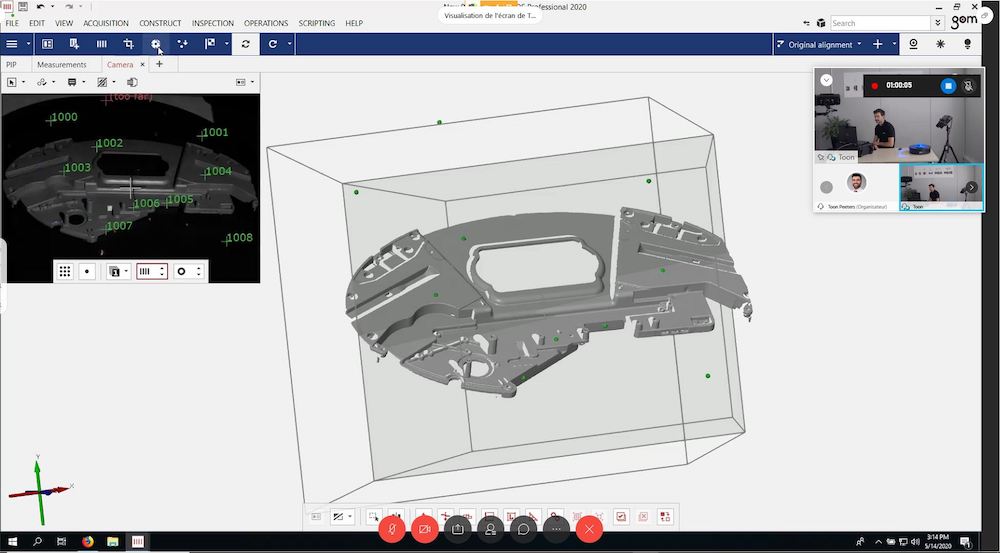

GOM Inspect’s Acquisition module is dedicated to the first step of the 3D scanning process: data capture.

In combination with the ATOS Q, the module works as a self-monitoring system to make sure no errors slip through the cracks. It monitors ambient light, potential part vibrations (e.g. if you bump into the desk), and the sensor and its calibration, for verifiable measuring accuracy.

Thanks to the automatic turntable, measurement data is acquired with minimal user intervention. The user only has to flip the part over for the scanner to capture previously hidden surfaces. Hence, the process is semi-automatic.

Inspection

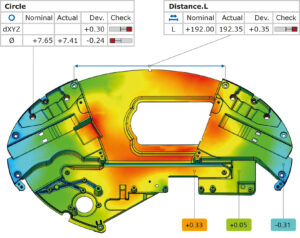

Once the 3D scans are done, the software automatically configures the Inspection module. It is extremely quick and easy to compare the 3D scanned data to a reference CAD file.

The software displays a general deviation overview with a range of colors, sort of like a heat map. Surface deviations appear clearly and it is possible to analyze specific sections of the part, with advanced thickness measurement functions.

When Product Manufacturing Information (PMI) is included in the CAD design file, all inspections are automatically generated without user intervention. Even when there is no PMI or CAD reference model, the software still offers intuitive options to enable users to inspect any part section or dimension they need, and with ISO or ASME conformity.

Reporting

After the scanning and inspection process, the Reporting module makes it easy to generate, view, and export results. Export formats include (3D)PDF, CSV, DMIS, QDas, Pi-webb, ASCII, IGES, and many more.

Additional formats are available for mesh and inspection exports to third-party software suites, although most of the tools needed for 3D scanning and metrology are already present in GOM Inspect.

Reports can be generated for individual parts, but also for multiple identical parts in the form of a statistical trend analysis where process capability studies can be done (e.g. Cp, Cpk, Sigma, Range, etc.).

Mesh editing

Mesh editing in the software is efficiently carried out in its own designated module, the Mesh editing module. It enables users to quickly modify and finalize the mesh with tools such as hole-filling, smoothing, refining, and more.

The software also allows you to create a sort of wireframe of the object by virtually slicing the mesh as much as needed. This wireframe can be of later use in CAD software to reverse-engineer the part. Several basic yet efficient feature recognition tools are also available.

3D scanning

After walking us through the various GOM Inspect modules, Toon launched the semi-automatic 3D scanning process.

It is always difficult to assess such a powerful machine’s performance without physically testing it for several use cases, but thanks to the GOM team’s expertise we were able to have a good look at the ATOS Q’s capabilities.

Its acquisition speed is amazing for a scanner of its category, even in full resolution mode. Two modes are available, a fast mode and a detailed mode. It is possible to do a fast scan of the entire part to obtain a first “draft”, and to top it with a higher-resolution scan.

The ATOS Q projects blue light fringes onto the part and sweeps from side to side while tuning fringe thickness. Everytime a sweep is performed, current operating conditions (e.g. temperature) are saved in the 3D scan’s metadata.

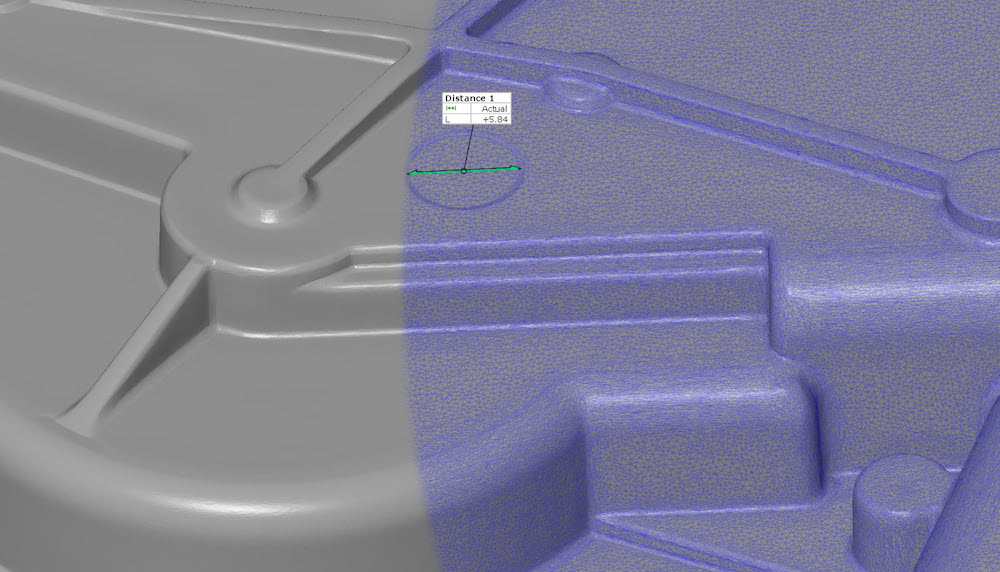

With only 8 captures for each side of the part (16 total) we obtained a very rich set of data, ready to be finetuned in GOM Inspect. We obtained the result only a minute or two after the 3D scanning process, and it was clean and detailed off the bat. The software’s algorithms are capable of detecting the areas where the mesh needs to be defined, such as edges, pockets, and corners.

The point density continuously varies to offer the best possible match between fidelity and mesh size. A smaller mesh is easier to analyse and process for all related measurements tasks, but also for collaboration and data transfer. This optimization is called Smart Triangulation.

Last but not least, it is possible to tell the software that certain zones are unwanted by cutting them out with points and/or planes. This feature can be used to automatically cut out a certain element for each and every scan (e.g. for bulk inspection of several identical parts).

In a similar fashion, the same reference points for similar parts can be reused from one scan to the next.

3D scanning results

Sample plastic injection-molded part

The part that Toon scanned has the typical properties you can find in scan samples: it doesn’t feature overly complex geometries and is made of grey plastic.

There were approximately 1.6 million points for this particular 3D scan. As previously explained, the result is a smart triangulated mesh. This means that the mesh’s triangles aren’t all the same size, they are adapted to the part:

- Flat areas are represented with larger triangles, since there is no need for so much detail on a flat surface. This generates less data, making the resulting file a lot lighter and easier to manipulate.

- Detailed areas boast a higher triangle density.

Value

The ATOS Q was designed to offer a very high level of performance that is on par with GOM standards, and at a more affordable price than the rest of the ATOS range.

One of the ATOS Q’s key selling points is the fact that it can be easily moved along an assembly line or from one site to another. It can’t be qualified as “portable”, but is without a doubt “transportable”.

The scanner also offers a lot of flexibility in part type and size thanks to its multiple lenses and is able to acquire difficult surfaces thanks to its blue light equalizer.

Both the hardware and software are fully optimized for metrology applications, delivering high precision and accuracy, and in-depth inspection reports. We were truly impressed with the scanner’s acquisition speed and the rich level of detail it provides within the meshes.

GOM Inspect software is a huge advantage in the ATOS Q’s value proposition, even in its free basic version. We’d recommend it even for use with competing 3D scanners intended for metrology applications.

The ATOS Q can be automated, which is another interesting perk. A first step could be to invest in just the sensor (already semi-automatic) and later complement it with an automated ScanBox.

One of the scanner’s limitations would be its maximum scanning volume, which is slightly limited despite the ATOS Q’s five interchangeable volumes. This can be worked around by using and realigning multiple captures.

Conclusion

The ATOS Q is an excellent product for three-dimensional coordinate measurement and deformation measurement. Simultaneously less expensive and more flexible than the ATOS 5 range, it is almost as powerful, too.

In the same price range, it faces the handheld Creaform HANDYSCAN Black Elite, which is also a very good product.

The ATOS Core line, also from GOM, is a cheaper alternative. These scanners’ resolution isn’t as high and they don’t all offer flexible scan volumes, but the ATOS Core line’s price tag makes them interesting for specific use cases.

English

English  Français

Français