3D bioprinting: Comprehensive guide and product selection

What is 3D bioprinting?

3D bioprinting is a process in which a machine called a 3D bioprinter is used to fabricate tissue structures that contain cells and an extracellular matrix. These structures can have uses in regenerative medicine, pharmaceutical testing, food production, and other areas.

Like regular 3D printing, 3D bioprinting creates 3D shapes layer by layer using a digital CAD file as a blueprint. However, by 3D printing with cells instead of plastics and metals, bioprinting can create precisely engineered tissue structures such as 3D printed organs. At present, these organs can only be used for research; in the future, however, they could be transplanted into human patients.

Although there are many different 3D bioprinting technologies and techniques, most 3D bioprinters print substances known as bioinks. These bioinks contain living cells, in addition to viscous materials like alginate or gelatin which allow the 3D bioprinter to create solid scaffolds on which the cells can survive and interact. Bioinks can contain differentiated cells (specialized, function-specific) or stem cells (nonspecific, later induced to become differentiated).

This guide contains an introduction to 3D bioprinting technologies and their applications, as well as an overview of the best 3D bioprinters on the market.

The top professional 3D bioprinters in 2023

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Axolotl Biosystems

Product data validated by the manufacturer.

| Axo A6 | 130 × 90 × 80 mm | Turkey | $ 40,000 | Quote |

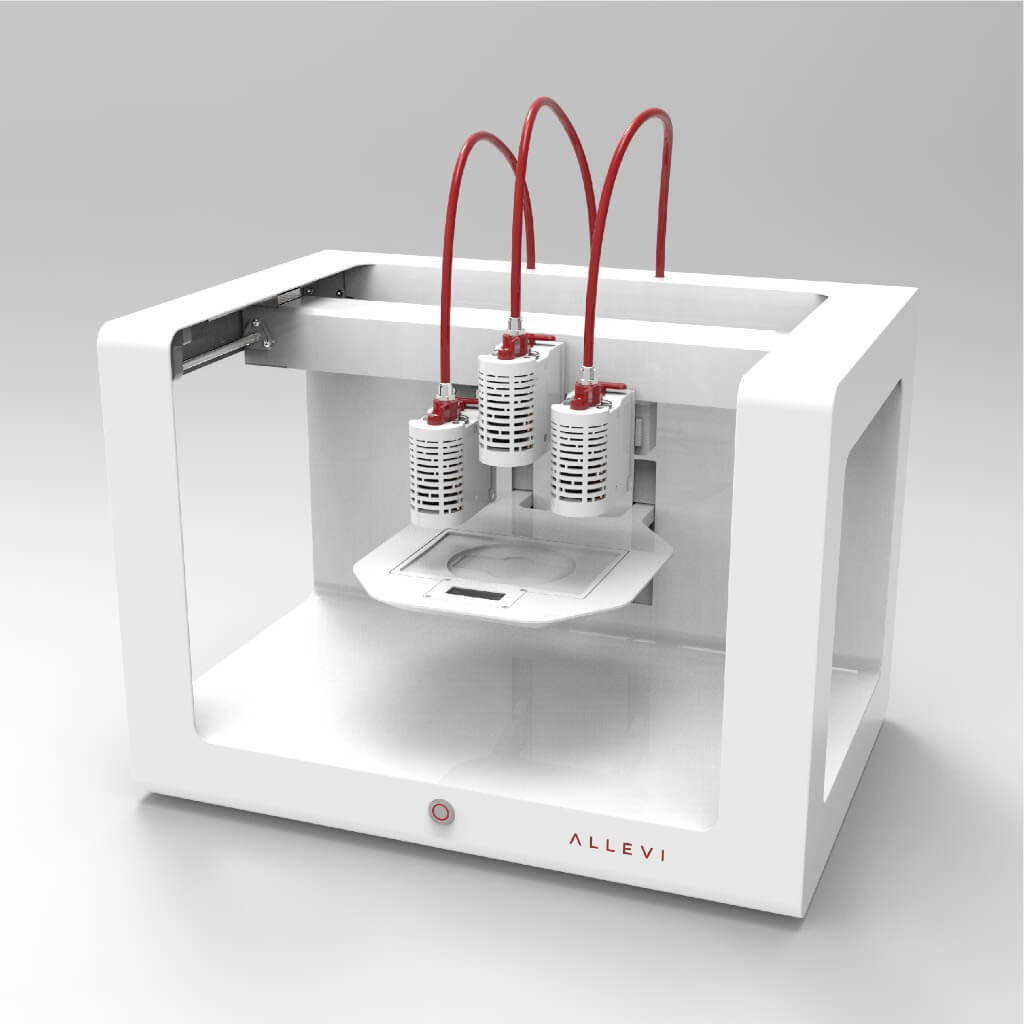

| Allevi | Allevi 3 | 130 × 90 × 60 mm | United States | $ 40,000 | Quote |

| ROKIT

Product data validated by the manufacturer.

| Dr. INVIVO 4D | 100 × 100 × 80 mm | South Korea | $ 45,000 | Quote |

| Brinter AM Technologies Ltd

Product data validated by the manufacturer.

| Brinter One | 300 × 174 × 80 mm | Finland | $ 55,000 | Quote |

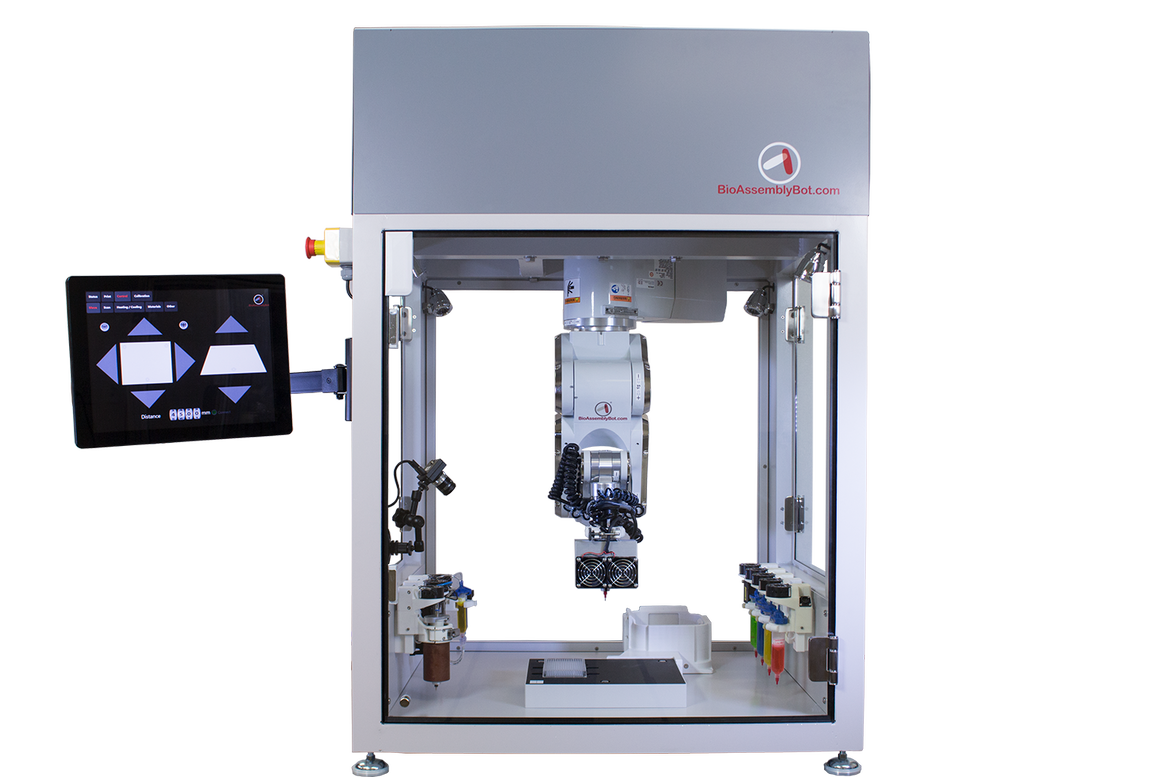

| Advanced Solutions | BioAssemblyBot | 305 × 254 × 178 mm | United States | $ 99,995 | Quote |

| GeSiM

Product data validated by the manufacturer.

| BioScaffold Printer BS3.2 | – | Germany | $ 150,000 | Quote |

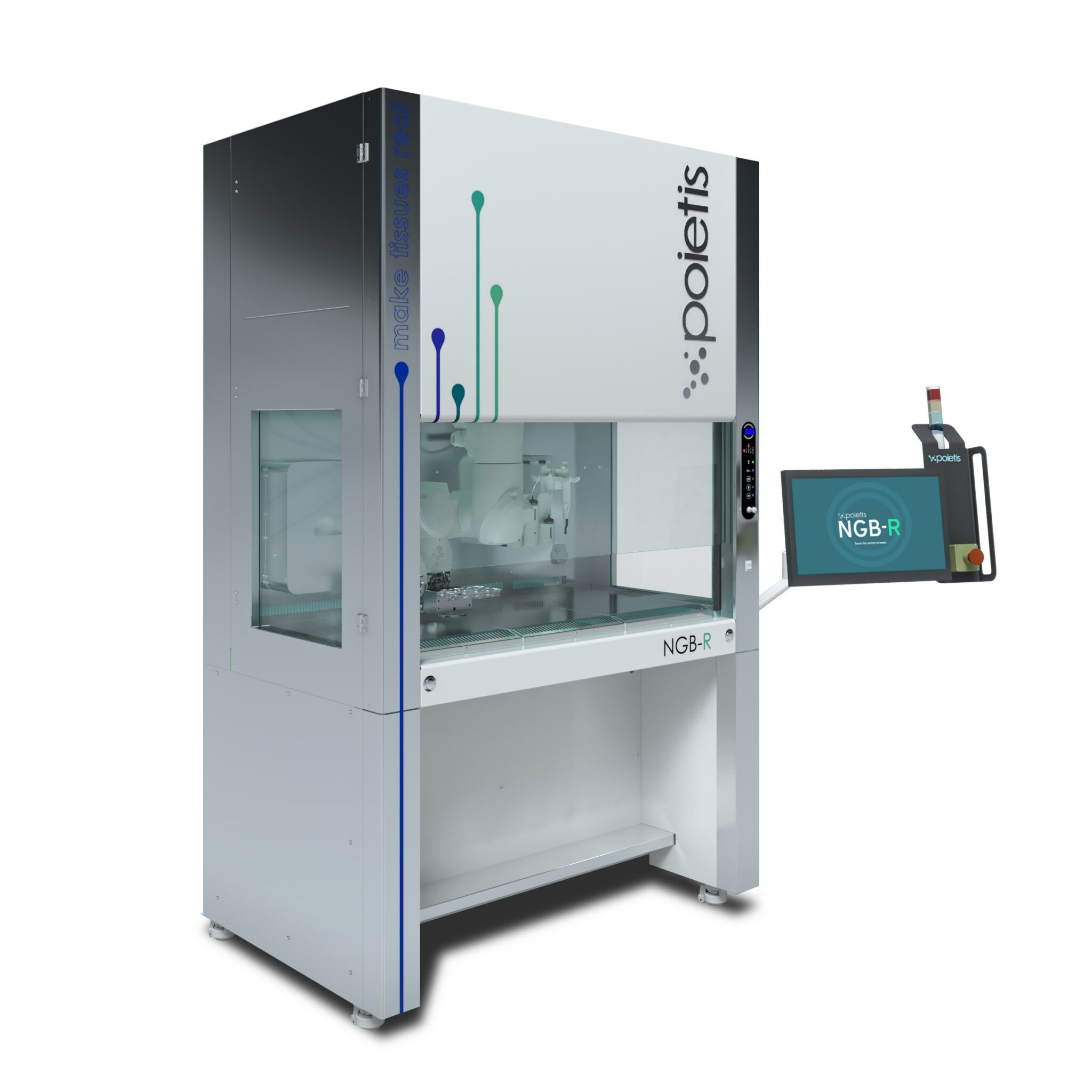

| Poietis

Product data validated by the manufacturer.

| NGB-R | – | France | $ 300,000 | Quote |

| CELLINK | BIO X | 130 × 90 × 70 mm | United States | upon request | Quote |

| Fluicell | Biopixlar | – | Sweden | upon request | Quote |

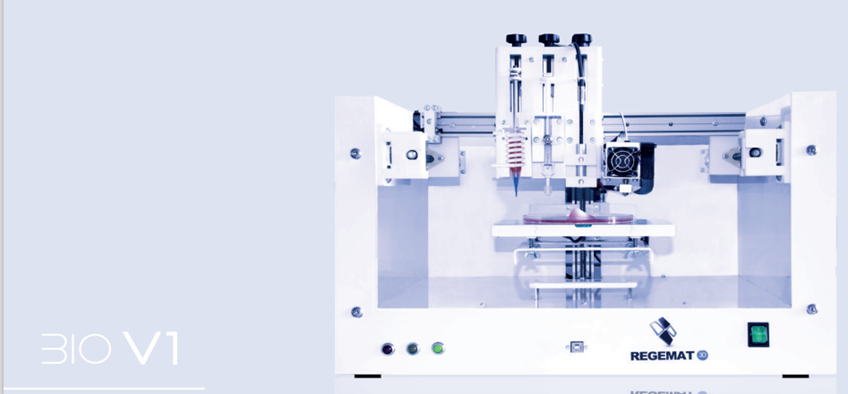

| REGEMAT3D

Product data validated by the manufacturer.

| V1 BioPrinter | 150 × 160 × 110 mm | Spain | upon request | Quote |

| UpNano | NanoOne Bio | 120 × 100 × 49 mm | Austria | upon request | Quote |

Build size: Generally refers to the maximum printable tissue size, which can vary greatly depending on the type of tissue being printed.

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Axolotl Biosystems

Product data validated by the manufacturer.

| Axo A6 | 130 × 90 × 80 mm | Turkey | $ 40,000 | Get a quote |

| Allevi | Allevi 3 | 130 × 90 × 60 mm | United States | $ 40,000 | Get a quote |

| ROKIT

Product data validated by the manufacturer.

| Dr. INVIVO 4D | 100 × 100 × 80 mm | South Korea | $ 45,000 | Get a quote |

| Brinter AM Technologies Ltd

Product data validated by the manufacturer.

| Brinter One | 300 × 174 × 80 mm | Finland | $ 55,000 | Get a quote |

| Advanced Solutions | BioAssemblyBot | 305 × 254 × 178 mm | United States | $ 99,995 | Get a quote |

| GeSiM

Product data validated by the manufacturer.

| BioScaffold Printer BS3.2 | – | Germany | $ 150,000 | Get a quote |

| Poietis

Product data validated by the manufacturer.

| NGB-R | – | France | $ 300,000 | Get a quote |

| CELLINK | BIO X | 130 × 90 × 70 mm | United States | upon request | Get a quote |

| Fluicell | Biopixlar | – | Sweden | upon request | Get a quote |

| REGEMAT3D

Product data validated by the manufacturer.

| V1 BioPrinter | 150 × 160 × 110 mm | Spain | upon request | Get a quote |

| UpNano | NanoOne Bio | 120 × 100 × 49 mm | Austria | upon request | Get a quote |

How does a 3D bioprinter work?

Although there are similarities between a 3D bioprinter and a 3D printer, a bioprinter must ensure the survival of living cells. This means it must have certain unique characteristics, such as the ability to print at mild temperatures.

Most bioprinters work by printing a kind of 3D gel known as a bioink, which comprises cells and a printable biomaterial like gelatin. Bioinks are similar to hydrogel biomaterials — which researchers use to create non-printed tissue structures, often in microplates — but with one key difference: bioinks are stable enough to be extruded or deposited from a printer.

How the bioink is manipulated depends on the chosen bioprinting technology.

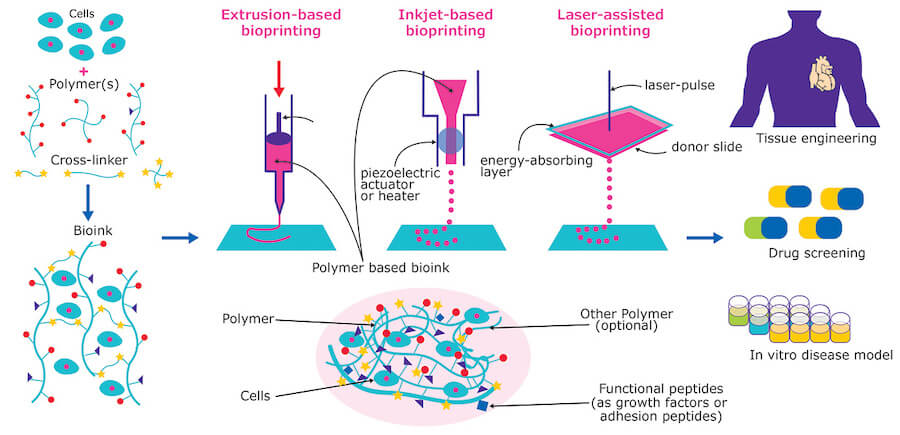

Extrusion bioprinting

The form of 3D bioprinting most similar to FDM 3D printing is extrusion-based bioprinting. This technology uses a computer-controlled print head to extrude, layer by layer, a highly viscous bioink onto a surface such as a petri dish. The extrusion may be achieved by air pressure, pistons, or a reciprocating screw.

Inkjet bioprinting

Inkjet 3D bioprinting, sometimes called drop-on-demand bioprinting, is a fast and highly accurate bioprinting technique in which a bioink is printed in droplets onto a surface. While inkjet bioprinting allows for the precise control of cells, it is less effective for 3D printing scaffolds, since its bioinks must have very low viscosity.

Laser-assisted bioprinting

Unlike extrusion and inkjet 3D bioprinters, laser-assisted 3D bioprinters do not use a nozzle to dispense bioink. Instead, these bioprinters direct UV light onto a vat of photosensitive bioink, which hardens when exposed to light. Like other Stereolithography (SLA) printers, the bioprinter has a moving platform to enable the printing of subsequent layers.

Misc. bioprinting technologies

Other forms of 3D bioprinting are less easily categorized. For example, some 3D bioprinting companies have developed systems that 3D print cells onto a needle array instead of using a biomaterial scaffold. With this technique, clusters of pure cells– not mixed with other biomaterials– are skewered onto upright needles to create 3D tissue structures.

Overview of the top 3D bioprinters in 2023

Rokit Healthcare is a biotechnology company based in South Korea. Its product portfolio includes 3D bioprinters, bioinks, skin modeling products and anti-aging solutions.

The Dr. INVIVO 4D is a 3D bioprinter with three extruder options: filament extruder, syringe dispenser and hot-melting pneumatic dispenser. The machine pays extra attention to sterilization, with a H14 HEPA filter and UV lamp included. Compatible materials include bioinks, biopolymers and ceramics.

The 3D bioprinter is sold in three variations: Standard, Upgrade and Premium, with the Premium version offering the widest range of extrusion types.

Brinter is a Finnish bioprinting company offering solutions to businesses and researchers in pharmacology, biotechnology and cosmetics.

The company’s Brinter 3D BioPrinter is an extrusion-type 3D bioprinter designed for the easy changing of print heads. It can process materials of varying viscosity, and its integrated camera allows for remote monitoring. Brinter has designed a range of print heads for the machine, including the MicroDroplet tool, Pneuma Tool, and Visco Tool.

Brinter also produces a range of bioinks made from biomaterials like nanocellulose, collagen, and fibrinogen.

Regemat is a Spanish biotech company that specializes in creating tailored bioprinting systems for individual companies, researchers and applications.

The Regemat Bio V1 is a 3D bioprinter designed to print osteochondral tissue, but it can also be used in many other tissue applications.

The printer offers three extrusion types — individual pore filling, injection volume filling and fused deposition modeling (FDM) — and works with six unique print heads: extrusion syringe, two-component syringe, UV light curing system, IR light curing system, cold syringe module and heated syringe module.

Regemat’s bioprinting system is used in hospitals and universities in over 20 countries around the world.

Allevi, an American bioprinting company, creates 3D bioprinters and bioinks for use in medical research and drug discovery.

The Allevi 3 is a triple-extruder 3D bioprinter with heated print bed, print head temperature control and photocuring possibilities. The extruders are powered by compressed air, with the pneumatic system suitable for a range of viscous biomaterials.

Recommended applications include tissue engineering, disease modeling, organ-on-a-chip, pharmaceutical development and dentistry.

All Allevi printers are designed with simplicity in mind: the company says its bioprinters are some of the market’s easiest to use.

Axolotl Biosystems Axo A6 overview

The Axo A6 is a 3D printer produced by Axolotl Biosystems, a manufacturer based in Turkey.

It uses the Extrusion bioprinting technology to produce bio/organic parts using liquid feedstock.

It offers a build volume of 130 × 90 × 80 mm.

Advanced Solutions is a biofabrication company, initially founded in 1987 as a reseller of Autodesk products.

The BioAssemblyBot is, according to Advanced Solutions, the world’s only six-axis 3D bioprinter, complete with a robotic arm print head for greater mobility and flexibility.

Unlike some other bioprinters, it also functions as a kind of incubator, manipulating printed tissue structures over a prolonged period of time. Advanced Solutions therefore markets the machine as an all-in-one biofabrication solution.

The BioAssemblyBot uses pneumatic and mechanical extrusion technology and is suitable for the fabrication of 3D printed tissue, 3D printed organs, cell spheroids and more.

GeSim, based in Germany, is a micromachining specialist that has developed several bioprinting technologies.

The BioScaffolder 3.2 is a pneumatic extrusion-based 3D bioprinter designed for tissue engineering research. When loaded with highly viscous bioinks, the BioScaffolder 3.2 can be used to fabricate 3D printed tissue, while its three extruders allow for multimaterial printing.

Applications include the printing of porous structures, fabrication of metal implants with soft polymer layers and gradient mixing of biopolymers.

GeSim says it can build customized versions of its BioScaffolder machines tailored to specific tissue engineering applications.

Poietis is a French biotechnology company that claims to have invented 4D bioprinting technology. Its bioprinters are used by leading pharmaceutical and cosmetic groups for product testing.

The NGB-R is a commercial bioprinter designed for R&D applications. It uses laser-assisted bioprinting technology, offering single-cell resolution and high cell viability. Poietis says the printer provides 4D bioprinting by adapting to the natural timespan of biological processes such as cell proliferation, migration and differentiation.

The Poietis NGB-R is an all-in-one platform, complete with a robotic arm for automation and additional nozzle-style print heads which complement the machine’s primary laser technology (1 laser printhead and 3 micro-valve heads).

UpNano NanoOne Bio overview

The NanoOne Bio is a 3D printer produced by UpNano, a manufacturer based in Austria.

It uses the Two-photon polymerization technology to produce thermosets parts using resin feedstock.

It offers a build volume of 120 × 100 × 49 mm.

CELLINK is an American bioprinting company that in 2016 commercialized the world’s first bioink. It produces a wide range of bioprinting systems and materials.

The BIO X is a 3D bioprinter that accommodates various deposition methods, including pneumatic extrusion, electromagnetic dropping and photocuring. CELLINK Has designed eight compatible print heads for the printer, three of which can be used simultaneously, and has fitted the machine with a heated print bed.

Cleanliness is key for the BIO X, which uses a HEPA H14 filter and programmable UV-C germicidal lamps for sterilizing the printing environment.

Fluicell is a public biotech company founded in 2012 as a spinoff from Chalmers University of Technology in Sweden. Its products are primarily used by researchers in drug development and cell biology.

The Biopixlar system is a high-resolution bioprinting platform offering a high level of control over individual cell placement. The bioprinter uses “microfluidic hydrodynamic confined flow technology” to dispense cells in 2D and 3D arrangements, and is designed primarily for organ-like tissue structures that can be used in drug testing.

A novel feature of the Biopixlar 3D bioprinter is its control interface: users can operate the machine using a video game-style joypad.

Upcoming 3D bioprinters

There are several interesting 3D bioprinting systems to expect over the next few months and years:

Alternative 3D bioprinters and special mentions

These 3D bioprinters are either extremely advanced machines or aren’t commercially available:

Entry-level 3D bioprinters

Some manufacturers produce relatively affordable 3D bioprinters for educational purposes:

- Hyrel 3D Engine HR ($8,000)

- FELIXprinters BIOprinter ($10,000)

What can 3D bioprinting be used for?

3D printing with cells opens up possibilities in many disciplines, from healthcare to cosmetics. These are some of the most common 3D bioprinting applications.

Healthcare

Perhaps the most significant of 3D bioprinting applications, medical and healthcare research has come on leaps and bounds thanks to bioprinting.

By using a 3D bioprinter to create 3D printed tissue, researchers can carry out drug screening to see how pharmaceuticals impact human tissue — without recruiting humans for potentially harmful medical trials.

Additionally, by 3D printing organs — or miniature approximations of them — with a 3D bioprinter, researchers can perform disease modeling. A tiny 3D printed heart model, for example, can be used to better understand how heart disease impacts the human body.

Another medical application of bioprinting is the 3D printing of skin patches. Medical researchers are developing techniques for bioprinting autologous skin cells in order to treat burns and deep wounds, and because human skin is flat and neatly layered, it is easier to print and develop than other artificial organs.

Cosmetics

Bioprinting can be used to fabricate 3D printed skin, and this process has important uses beyond healthcare — in the cosmetics and beauty industry, for example.

3D bioprinting applications in cosmetics include testing beauty products for allergic reactions and other negative side effects without live human test subjects. 3D printed hair can be used for similar purposes.

A future application of 3D bioprinting in cosmetics could be the use of 3D printed skin for cosmetic surgery and facial reconstruction.

Food

3D printing with cells may soon have important applications in food production. Since a 3D bioprinter can create tissue scaffolds, it can effectively turn stem cells and other biomaterials into lab-grown meat.

Synthetic bioprinted meat is better for the environment than animal farming and involves no harm to living creatures. Several companies and research groups have developed methods for incubating bioprinted structures so that muscle fibers develop, resulting in an edible synthetic product.

3D printed meat is softer than organic meat, but this is seen as a fairly minor issue for the industry.

Current limitations of bioprinting

The 3D bioprinting of organs has led to major advances in drug screening, disease modeling, and other areas.

However, the holy grail of medical 3D bioprinting is the development of 3D printed organs for human transplantation. In theory, this practice is possible, since researchers can already take a patient’s cells and bioprint them into 3D structures, which can then be incubated to grow into approximations of human organs.

3D printed artificial organs could someday eliminate the need for an organ donor waiting list, as patients could simply “grow” personalized replacement organs using 3D bioprinting techniques. Moreover, since each patient would contribute their own cells, researchers believe the process would sidestep the problem of transplant rejection — something that occurs when a patient receives, for example, the kidney of another human.

But 3D printed organs are, at present, too crude to be used for transplantation. In 2023, a 3D printed heart or 3D printed kidney lacks the proper vasculature to function within the human body.

The bottleneck in 3D printed organ development is not so much the 3D bioprinting techniques themselves, but the culture and incubation processes employed after printing, which are not yet advanced enough to turn a bioprinted tissue structure into a fully functional organ.

How much does 3D bioprinting cost?

Commercial 3D bioprinting is an expensive process, with high-end machines like the Poietis NGB-R ($200,000) costing significantly more than even the most high-end polymer 3D printers.

However, some bioprinting systems aimed at university researchers — the Regemat Bio V1 ($25,000), for example — are more affordable.

Other obstacles to commercial 3D bioprinting, beyond the machine unit cost, include the complex process of acquiring human stem cells and the extensive legal effort required to bring 3D bioprinting solutions to market.

Bioprinting regulations: FDA and beyond

3D bioprinting has made huge advances over the last decade, but the legal framework surrounding 3D printed organs and other bioprinted matter is not yet clearly defined.

In the United States, medical products and procedures are regulated by the Food and Drug Administration (FDA), whose Center for Biologics Evaluation and Research is responsible for cell and tissue-based products. When 3D bioprinted organs become marketable, their regulation will likely be assigned to this department.

At present, 3D printed organs do not easily apply to any existing FDA regulations. However, researchers have suggested they would fall under the category of biological products, which include things like therapeutic serums, vaccines, allergenic products, and proteins.

Given their synthetic nature and ultimate purpose, 3D printed organs may even be classified as drugs.

Other global regulatory bodies are also in the early stages of responding to 3D bioprinting. The countries fastest to publish 3D bioprinting guidance have been Japan (Pharmaceuticals and Medical Devices Agency) and South Korea (Ministry of Food and Drug Safety), both of which offered official guidance on 3D bioprinting before the year 2016.

When a research group finally creates 3D printed artificial organs suitable for transplantation, the timeframe for testing and regulating the organs will likely be long.

3D bioprinting FAQ

It is possible to bioprint structures that closely resemble human organs. They can be used for research and testing, but they are not suitable for transplantation into a human body.

3D bioprinting has been carried out with a range of cell types. Adult stem cells can be procured by blood apheresis, bone marrow harvesting, and other techniques.

A bioink contains living cells and certain biomaterials – gelatins, alginates, fibrin, etc. – that allow the bioink to be processed by a printer.

No. 3D bioprinters generally operate at mild temperatures to preserve living cells in the bioink, whereas FDM 3D printers heat filament above 200°C.

English

English  Français

Français