Micro 3D printers and micro AM

What is micro 3D printing?

Micro 3D printing is the practice of 3D printing parts with micro-sized features. Spanning multiple technologies including microstereolithography and micro laser sintering, micro 3D printing requires the use of micro 3D printers capable of achieving incredibly fine resolutions — sometimes below the micron/micrometer (μm) level.

Also known as 3D microfabrication, micromanufacturing, or micro additive manufacturing (µAM), micro 3D printing may be considered a form of microfabrication, a catch-all term that also includes micromachining and semiconductor manufacturing processes like ion etching. Micro 3D printing is a comparatively new technology and is only now offering an alternative to these established processes.

A small number of micro-precision 3D printing technologies, such as two-photon polymerization, are also forms of nanofabrication technology since they can produce incredibly small structures with features measurable in nanometers (units one thousand times smaller than a micron).

This guide covers all the main micro 3D printing technologies and their applications, in addition to providing an overview of the market’s leading µAM systems.

Micro 3D printing technologies

Micro laser sintering

At the macro level, selective laser sintering (SLS) is a form of metal additive manufacturing in which a computer-controlled laser beam sinters particles of metal powder to make a 3D shape. A moving platform allows the printer to move from one 2D layer to the next.

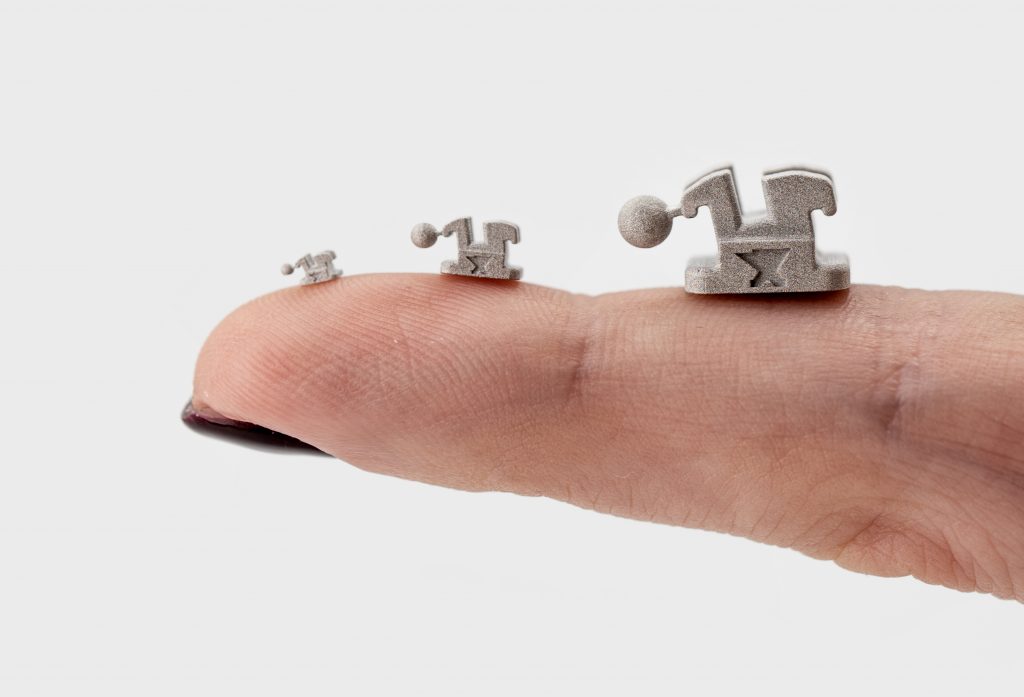

Some micro 3D printers use micro laser sintering, a form of high-precision metal 3D printing, to make very fine-featured metal structures. The technology is similar to SLS, but with up to three main differences: a smaller laser spot size, a platform that can move in smaller increments and therefore produce thinner layers, and powders with a small-diameter particle size.

The ability to produce micro metal parts makes micro laser sintering particularly useful in areas like semiconductor production, aerospace, and watchmaking.

Microstereolithography

Microstereolithography or micro SLA is a form of stereolithography adapted for micro 3D printing. Like SLA, the high precision micro 3D printing technology uses a photosensitive polymer resin which is selectively cured, layer by layer, using a high-precision light source such as a laser.

A related technology is projection microstereolithography (PµSL), which uses UV projections instead of a laser and can cure entire 2D layers at once. In this way, PµSL resembles the macro 3D printing process of digital light processing (DLP) as much as stereolithography.

Micro SLA produces micro parts that may be used in industries such as medicine, while clear resin parts can be used in areas like microfluidics and microoptics.

Two-photon polymerization

A form of multiphoton lithography, two-photon polymerization (2PP) is a maskless direct laser writing technology capable of achieving incredibly high resolution, often well below the micron level.

The 2PP process works a bit like SLA and other photopolymerization processes, only with a much more localized area of polymerization. During the process, a photoinitiator molecule within a photoresist absorbs two photons simultaneously. This initiates polymerization around a laser beam spot, creating a single voxel. This nanofabrication process is repeated until a 3D shape is built out of multiple voxels.

Materials for two-photon polymerization include acrylic and epoxy resins, and applications include medical microdevices, microoptics, and material engineering.

Other µAM technologies

Novel methods of microfabrication are constantly in development. Some less common micro-precision 3D printing technologies include:

- Electrochemical deposition

- Nano ink jetting

- Glass micro 3D printing

- Metal lithography

The best micro 3D printers in 2023

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Microlight3D

Product data validated by the manufacturer.

| microFAB-3D | ⌀ 3 x 20 mm | France | $ 120,000 | Quote |

| Femtika | Laser Nanofactory | – | Lithuania | $ 415,000 | Quote |

| 3D MicroPrint | DMP60 series | ⌀ 60 x 30 mm | Germany | upon request | Quote |

| BMF

Product data validated by the manufacturer.

| microArch P130 | 4 × 3 × 10 mm | United States | upon request | Quote |

| Exaddon

Product data validated by the manufacturer.

| CERES | 100 × 70 × 60 mm | Switzerland | upon request | Quote |

| FEMTOprint | FEMTOprint Platform | – | Switzerland | upon request | Quote |

| Incus

Product data validated by the manufacturer.

| Hammer Lab35 | 89.6 × 56 × 120 mm | Austria | upon request | Quote |

| Multiphoton Optics | MPO100 TPP | 100 × 100 × 100 mm | Germany | upon request | Quote |

| Nano Dimension

Product data validated by the manufacturer.

| Fabrica Tera 250 | 50 × 50 × 100 mm | Israel | upon request | Quote |

| Nanogrande | MPL-1 | – | Canada | upon request | Quote |

| Nanoscribe

Product data validated by the manufacturer.

| Quantum X shape | 50 × 50 × 20 mm | Germany | upon request | Quote |

| UpNano | NanoOne | 120 × 100 × 49 mm | Austria | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Material | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|---|

| Microlight3D

Product data validated by the manufacturer.

| microFAB-3D | ⌀ 3 x 20 mm | Thermosets | France | $ 120,000 | Get a quote |

| Femtika | Laser Nanofactory | – | Thermosets | Lithuania | $ 415,000 | Get a quote |

| 3D MicroPrint | DMP60 series | ⌀ 60 x 30 mm | Steel | Germany | upon request | Get a quote |

| BMF

Product data validated by the manufacturer.

| microArch P130 | 4 × 3 × 10 mm | Thermosets | United States | upon request | Get a quote |

| Exaddon

Product data validated by the manufacturer.

| CERES | 100 × 70 × 60 mm | Gold, Copper, Nickel | Switzerland | upon request | Get a quote |

| FEMTOprint | FEMTOprint Platform | – | Glass | Switzerland | upon request | Get a quote |

| Incus

Product data validated by the manufacturer.

| Hammer Lab35 | 89.6 × 56 × 120 mm | Gold, Cobalt chrome, Copper, Silver, Steel, Titanium, Tungsten | Austria | upon request | Get a quote |

| Multiphoton Optics | MPO100 TPP | 100 × 100 × 100 mm | Thermosets | Germany | upon request | Get a quote |

| Nano Dimension

Product data validated by the manufacturer.

| Fabrica Tera 250 | 50 × 50 × 100 mm | Thermosets | Israel | upon request | Get a quote |

| Nanogrande | MPL-1 | – | Platinum, Aluminum, Copper, Steel, Titanium | Canada | upon request | Get a quote |

| Nanoscribe

Product data validated by the manufacturer.

| Quantum X shape | 50 × 50 × 20 mm | Polymers, Others | Germany | upon request | Get a quote |

| UpNano | NanoOne | 120 × 100 × 49 mm | Thermosets | Austria | upon request | Get a quote |

Overview of the best micro 3D printers in 2023

Femtika is a Lithuanian company spun off from the Vilnius University Laser Research Center that specializes in hybrid nanofabrication systems.

The Femtika Laser Nanofactory is a hybrid additive and subtractive nanofabrication machine that combines multiphoton polymerization with selective laser etching and laser ablation. Its main advantages are multimaterial fabrication — of, for example, etched glass microchannels with printed polymer nano filters — and support-free printing.

Femtika’s hybrid system is designed for industrial nanofabrication R&D in areas like biotech, medicine, microoptics, and photonics, as well as for academic research.

Multiphoton Optics, a subsidiary of Heidelberg Instruments Mikrotechnik based in Germany, is a two-photon polymerization specialist.

The company’s Multiphoton Optics MPO100 nanofabrication printer provides sub-micron resolution and is designed for polymer printing on substrates of various shapes and materials, including active devices like LEDs. The system is also capable of laser ablation.

Built for academic and industrial users, the MPO100 has applications in microoptics, photonics, micromechanics, and biomedicine.

German company Nanoscribe is a nanofabrication specialist that has developed technology based on two-photon lithography.

The Nanoscribe Quantum X nanofabrication printer combines two-photon lithography with grayscale lithography, providing sub-micron resolution and precise voxel control.

The system can fabricate biomedical components and bioinspired microenvironments suitable for cell studies, as well as lab-on-a-chip structures for the study of neuronal networks, cell growth, migration, or stem cell differentiation. Other printable parts include microscale biomedical instruments (e.g. microneedles), microfluidic systems, and photonic interconnects.

Austria’s UpNano is a two-photon polymerization company that has developed two versions of its nanofabrication micro 3D printing system.

The UpNano NanoOne is a 2PP printer with an especially high throughput of up to 200 cubic millimeters per hour and a resolution of 0.17 microns. The system is suited to tasks in microoptics, microfluidics, micromechanics, and medical engineering.

UpNano has also developed the NanoOne Bio, a micro 3D bioprinter that can print a gelatin-based hydrogel to make structures that mimic the microenvironment of cells.

French company MicroLight 3D makes two-photon polymerization 3D printers compatible with polymers and biomaterials, building on 15 years of research at the University of Grenoble Alpes (UGA).

The company’s µFAB-3D is a 2PP nanofabrication system with a resolution of 0.2 microns, enabling the printing of microstructures and nanostructures with very smooth surfaces that do not require post-processing. It is available as a basic model or as a customized system with user-specific features.

The µFAB-3D can be used in areas like microoptics, microfluidics, cell biology, and metamaterials.

Canadian microfabrication specialist Nanogrande is one of a handful of companies making 3D printing technology for micro metal parts.

The Nanogrande MPL-1 uses a patented form of laser sintering technology that Nanogrande calls Power Layering Technology.

Compatible with several metals including titanium, platinum, and gold, the micro 3D printer is suitable for applications in watchmaking, jewelry making, electronics, and mold tooling.

Switzerland’s FEMTOprint is a company unique in its goal of creating micro 3D printers capable of fabricating glass microdevices.

The FEMTOPRINT platform uses a light source to modify the refractive index and density of the material, enabling the production of sub-micron glass structures usable in fields like microoptics, microfluidics, electronics, and micromolding.

FEMTOprint offers microdevice R&D, prototyping, and production services, in addition to selling its micro 3D printing platform to academic and industrial users.

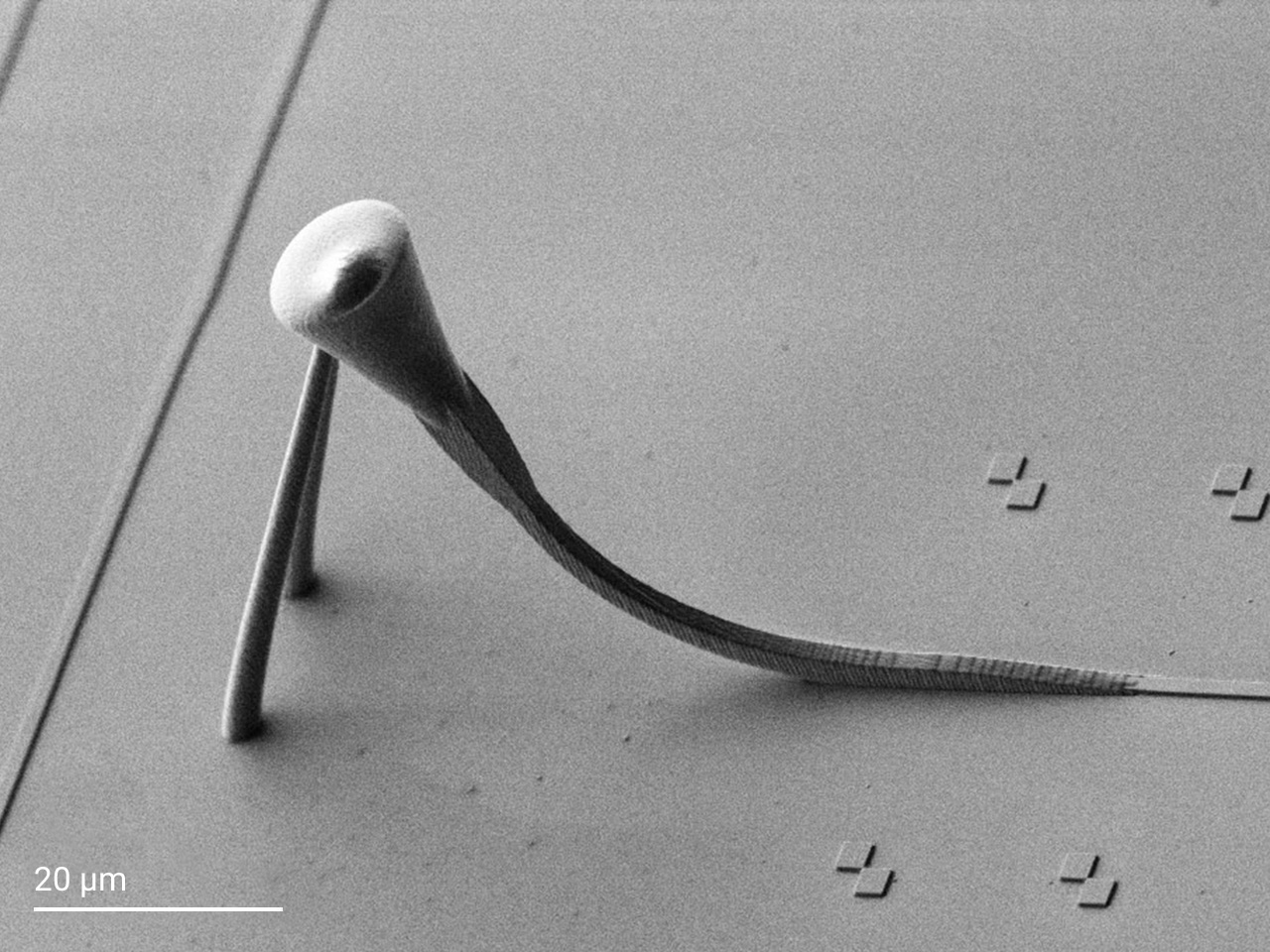

Exaddon, based in Switzerland, is a metal micro 3D printing company spun off from biotech company Cytosurge AG.

The Exaddon CERES uses electrochemical deposition (an ion tip pushes out tiny quantities of ion ink which are transformed into solid metal by a reduction reaction) to fabricate parts at sub-micron resolution. The machine can also locate substrates with sub-micron accuracy to enable direct printing onto other micro components.

The ability of the CERES to print onto substrates is useful in brain-machine interfaces, semiconductor surface modification, and in high-frequency communications components, e.g. microneedles on a chip.

Based in Israel, micro AM company Fabrica Group (ex Nanofabrica) has developed its own Micro Adaptive Projection technology, a form of micro digital light processing (DLP).

The company’s 3D printing system, the FABRICA 2.0, moves its build plate through a vat of photosensitive resin in increments of 1 micron, while the XY accuracy of its projection system is also 1 micron. Materials include an ABS-like resin and a ceramic-filled resin.

A relatively large build volume allows for the simultaneous microfabrication of many micro parts, allowing users to use the FABRICA 2.0 for prototyping or mass production.

Boston Micro Fabrication, a micro 3D printing company based in Massachusetts, develops 3D printing hardware and provides micro AM services.

The company’s BMF microArch P130 uses a DLP-like technology called Projection Micro Stereolithography (PµSL) and offers an optical resolution of 2 microns. It is compatible with BMF materials — including a high-temp resin and a biocompatible resin — and third-party materials. The microArch S130 offers a larger build envelope.

BMF’s micro-precision 3D printer has uses in electronics, microfluidics, medical device production, and elsewhere.

Germany’s 3D MicroPrint was founded via a collaboration between EOS and 3D-Micromac and focuses on micro laser sintering for the microfabrication of metal parts.

The 3D MicroPrint DMP60 series comprises three micro laser sintering systems: the DMP60 (nonreactive materials), the DMP63 (nonreactive and reactive; high-power laser option), and the DMP64 (highest resolution). The machines use an infrared fiber laser and an inert argon atmosphere.

3D MicroPrint says its systems are typically used by those in medicine, automotive, aerospace, semiconductor and MEMS production, energy and chemical, watchmaking, and jewelry making.

Incus, an offshoot of ceramic 3D printing company Lithoz based in Austria, is a metal 3D printing company that has developed a technology called Lithography-based Metal Manufacturing (LMM).

LMM, a photopolymerization process in which metal powder is dispersed throughout a photosensitive resin and selectively polymerized by a light source, is the foundation of the plug-and-play Incus Hammer printer. With part and material quality comparable to metal injection molding (even without post-processing), the Hammer offers wide material compatibility and industrial scalability.

Incus says its 3D printer — which can print non-flowable and non-weldable metals, including titanium and precious metals — has applications in aerospace, energy, medical, automotive, and jewelry making.

Micro 3D printing applications

Microfabrication and nanofabrication applications span a range of industries and areas of research, from electronics to lab-on-a-chip microfluidics.

Electronics

Miniaturization and lightweighting are a high priority in the electronics industry, and micro 3D printing enables the production of tiny electronics components like micro antennae, RF devices, and electrical contacts.

Some micro 3D printers can also print directly onto substrates such as LEDs and photodiodes, reducing the need for the assembly of micro components.

Aerospace & automotive

Micro 3D printing technology is becoming more commonplace in both the aerospace and automotive industries, where micro and nanoscale components have many uses.

One area of µAM receiving a lot of attention is the development and production of novel sensors that can detect pressure, temperature, and humidity — all of which require control and monitoring within vehicles.

Medical

The medical and healthcare sector can benefit from the use of microfabrication systems, both in clinical and research settings.

Many microoptics and microfluidics applications overlap with medicine, while microfabrication is also being used to develop micro drug delivery devices and biomedical instruments like microneedles and microporous membranes. Other medical applications include cell-sized micro-robots.

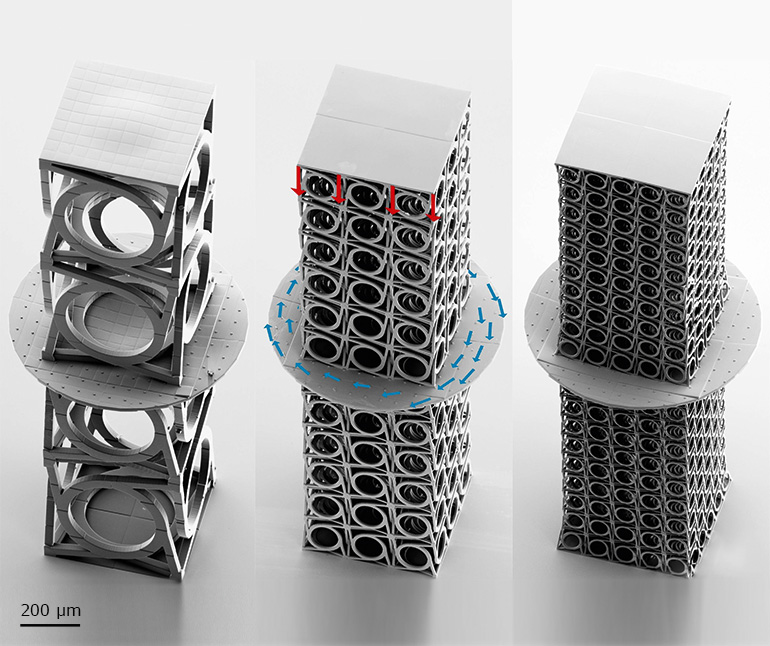

Metamaterials

A key application for microfabrication is the development and production of meta-materials or microstructures.

3D printed metamaterials are microstructures with highly sophisticated internal patterns that affect the physical behavior — the elasticity and resistance, for example — of the structure as a whole. These patterns, which can be generated automatically using topology optimization software, often take the form of lattices.

Printed metamaterials are used in mechanical engineering, aerospace, sound insulation, and other areas.

Microoptics

Microfabrication technologies that produce finely detailed and smooth-surfaced polymer structures are often suitable for the production of microoptics: optical systems typically measuring between a micron and a millimeter in size.

3D printed microoptics include micro-lenses, micro-prisms, compound lens systems, metalenses, and freeform optics. These can be used in optical telecom equipment, consumer electronics, and material processing equipment.

Microfluidics

Microfluidics is a field of science focused on the manipulation of tiny quantities of fluids, usually through precisely engineered channels. It has practical applications in areas like lab-on-a-chip technology, inkjet printing, and micro-thermal technologies.

Micro 3D printers can be used to fabricate microfluidic systems comprising extremely narrow fluid channels — which can be printed either directly or as masters (printing the would-be hollow area and molding around it) — as well as other microfluidic elements such as filters, nozzles, and capillary pumps.

Micro 3D printing vs comparable technologies

Micro 3D printing may be seen as an alternative to more established microfabrication processes like CNC micromachining and micro injection molding. However, these micro-precision technologies work in different ways and have different strengths and weaknesses.

CNC micromachining

CNC machining is a manufacturing process in which a cutting tool removes material from a workpiece according to computer instructions. Most CNC machines have minimal tolerances of around 50 microns, but CNC micromachining allows for much greater precision.

Many micro CNC machines (usually 5-axis machining centers, wire EDM, or sinker EDM machines) are capable of achieving tolerances below one micron, making micromachined parts comparable in scale to parts printed using micro 3D printers.

Advantages of CNC micromachining include a wide range of material options, especially metals, and the ability to machine micro features on macro parts.

Common micromachined parts include miniature gears, fiber optic components, waveguides for microwaves, microfluidic systems, micro components for medical monitoring equipment, and micro molds.

Micro injection molding

Micro injection molding or micromolding is a manufacturing process used to create very small molded thermoplastic parts with micron tolerances.

Like macro injection molding, the micromolding process involves forcing molten material into a metal mold (which may be produced using micro 3D printing, CNC micromachining, or another microfabrication process).

Although limited to thermoplastics, micromolding is a highly valuable process for fabricating large quantities of identical parts, with a far better production rate than micro 3D printing or CNC micromachining.

The micro injection molding process is widely used for the production of tiny items like microfluidic systems, miniature gears, micro fasteners and connectors, two-shot micro molded parts, and insert molded micro parts.

Micro injection molding can work in tandem with micro 3D printing, with the latter able to produce micro tooling. Small-batch 3D printed tooling can even be printed in non-metal materials using, for example, 2PP or micro SLA printers.

Future possibilities for micro 3D printing

Higher resolutions, new material options, and broader commercial availability are just some of the factors creating new possibilities for micro 3D printing.

Improvements in the technology will open up new possibilities such as 3D printed micro tooling with a lifespan of 1,000+ shots, smaller components for wearable electronics, improved biomedical devices, and faster micro-scale prototyping.

Swiss company Exaddon believes micro 3D printing will play a crucial role in the production of microscale high-frequency communication components for 6G networks, helping to create a “game-changing data transportation infrastructure.”

FAQ

The minimum feature size of macro 3D printers is limited by hardware such as stepper motors (and how finely they can move a build platform or printhead) and lasers (and the size of the laser spot).

Micro-precision 3D printers typically contain highly engineered pieces of hardware designed specifically for the fabrication of microscale parts; their function cannot be replicated by macro 3D printing hardware.

Microfabrication is a generic term for manufacturing processes (micro 3D printing, micromachining, etc.) capable of producing microscale parts, i.e. those measurable on the micron scale. Nanofabrication is another catch-all term, but for manufacturing processes that can produce nanoscale parts, i.e. those measuring well below 1 micron.

Some micro 3D printers, such as the Femtika Laser Nanofactory, are hybrid systems that can perform substractive microfabrication processes like etching. Others are capable of printing directly onto substrates such as microscale parts that have been made using other manufacturing processes.

Micro 3D printing can also be used to make tiny molds or patterns for use in micro injection molding.

English

English  Français

Français