Desktop SLS 3D printers: the best powder printers

What desktop SLS 3D printers are available on the market?

SLS (Selective Laser Sintering) is a 3D printing technology that uses a laser beam to sinter powdered material. This technique enables the 3D printing of detailed functional parts and prototypes.

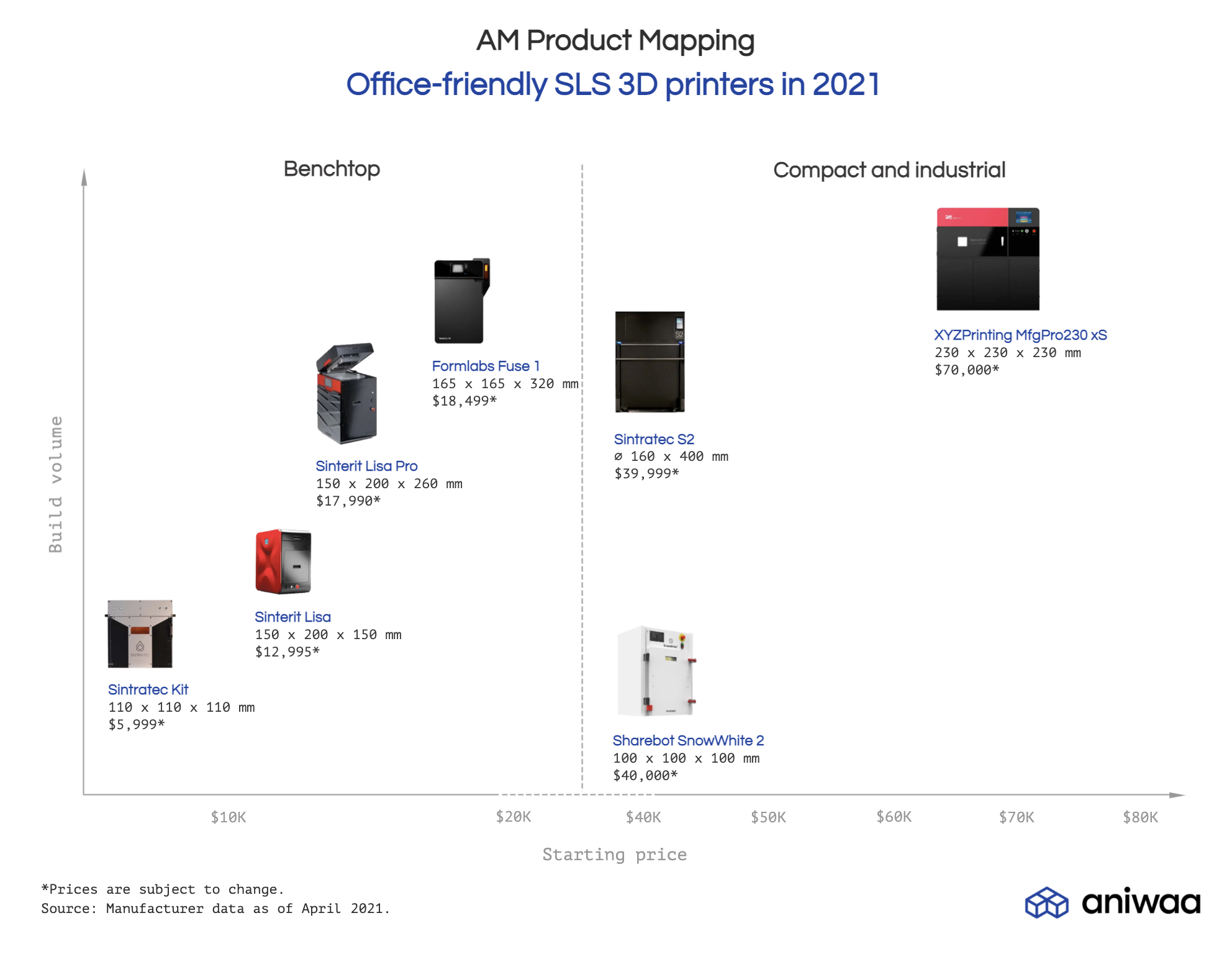

Five to ten years ago, SLS technology was exclusive to large, industrial additive manufacturing systems. In recent years, a more compact SLS 3D printer niche has been slowly emerging, with lower prices and office-friendly formats.

Starting at around $6,000, these benchtop or desktop SLS 3D printers enable SMEs to access accurate and advanced in-house prototyping without having to rely on external 3D printing services. They are able to print with powder materials such as Nylon, TPE, and other thermoplastics.

In this guide, we take a closer look at which desktop SLS printers are available on the market from brands like Sintratec, Sinterit, and Formlabs.

The best desktop SLS printers for professionals

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm | Switzerland | $ 5,999 | Quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm | Spain | $ 12,900 | Quote |

| Sinterit | Lisa | 150 × 200 × 150 mm | Poland | $ 12,995 | Quote |

| Sinterit | Lisa Pro

This product has been reviewed by our team.

| 150 × 200 × 260 mm | – | $ 17,990 | Quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm | United States | $ 18,499 | Quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm | Russian Federation | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm | Switzerland | $ 5,999 | Get a quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm | Spain | $ 12,900 | Get a quote |

| Sinterit | Lisa | 150 × 200 × 150 mm | Poland | $ 12,995 | Get a quote |

| Sinterit | Lisa Pro

This product has been reviewed by our team.

| 150 × 200 × 260 mm | – | $ 17,990 | Get a quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm | United States | $ 18,499 | Get a quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm | Russian Federation | upon request | Get a quote |

What is SLS (Selective Laser Sintering) technology?

Up until early 2014, Carl Deckard from Structured Polymers held a patent on Selective Laser Sintering 3D printing technology. Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

How does Selective Laser Sintering work?

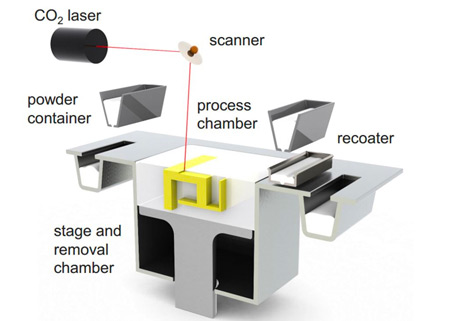

This technology uses a laser to sinter powdered material. In other words, a powerful laser beam selectively melts and fuses tiny powder particles together.

Once a layer is finished, more powder is rolled and spread onto the print bed. The process repeats itself layer after layer. The excess powder stays in the powder bed, thus automatically providing support for the object and its intricacies (though supports are still needed when it comes to metal 3D printing).

When the 3D printing process is finished and the powder bed has cooled down, the objects can be removed. The excess powder material is then to be brushed off to reveal the final part. Aside from powder removal, the parts require little to no post-processing for basic applications.

Overview of the best desktop SLS printers

The Sinterit Lisa is a plug-and-play desktop SLS 3D printer made by Polish manufacturer Sinterit. It is one of the most affordable SLS 3D printers actually available on the market.

This 3D printer offers a relatively large build volume for a desktop 3D printer, and even more so for an SLS 3D printer in this price range. With the Lisa it is possible to 3D print flexible material (Flexa Black/Grey) or rigid, strong material (PA12).

In comparison with the regular Lisa, the Lisa Pro boasts various upgrades and features. For starters, the Pro version is equipped with a Nitrogen chamber, for wider material compatibility.

The Lisa Pro SLS printer also provides a bigger print volume as well as a larger touchscreen than the Lisa.

Our review at Sinterit headquarters: Sinterit Lisa Pro review

The Sintratec Kit started out as an Indiegogo crowdfunding campaign in 2014. It is one of the most affordable SLS 3D printers available today.

The Kit requires around four days of assembly. Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Formlabs, originally an SLA 3D printer manufacturer, introduced their first SLS 3D printer – the Fuse 1 – mid 2017. It is officially available since January 2021.

The printer works with Formlab’s PreForm software, and features two separate build chambers. This enables users to immediately launch a second build once the first job is complete.

After the printing process, the chamber can be directly placed as-is in the Fuse Sift, an all-in-one sieving machine that collects unused powder and prepares it for future builds by mixing it with fresh powder. The Fuse 1 can work with up to 70% of recycled powder, so each new build only requires 30% of fresh material (which costs around $100/kg).

Note: Natural Robotics launched the VIT SLS via Kickstarter in 2017. As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

The VIT SLS offers a relatively large build volume compared to the other 3D printers in this range.

Note: This 3D printer is only available in a limited geographical region.

RED ROCK 3D is a new 3D printer manufacturer from Russia. Its RED ROCK SLS 3D printer offers a relatively large build volume compared to most of the other desktop SLS 3D printers in this selection.

Little information about this SLS 3D printer is available on the RED ROCK 3D website, which hasn’t been updated in a while (as of January 2021).

Compact industrial-grade SLS 3D printers: our picks

The following printers are larger than the benchtop SLS printers from our main selection but are still relatively compact considering the usual size of industrial SLS systems.

The Sintratec S2 is an all-in-one modular and scalable SLS 3D printing system with an onboard camera and large, intuitive touchscreen. It integrates a material preparation module as well as a depowdering station for semi-automatic workflows.

Optional stations include a blasting station, vortex unit, and a polishing station, enabling easier part post-processing.

The SnowWhite 2 features a powerful CO₂ laser that is able to sinter a range of materials including PA 12, PA 11, and TPU, as well as powder loaded with carbon or glass fiber or even aluminum.

All unused powder can be recycled. The printer can be powered up in ten minutes and the minimum amount of powder required to start a print is 300g.

XYZprinting’s range of products is one of the industry’s most diverse in terms of technology, suiting both consumers and businesses.

The MfgPro230 xS is an open-source system, meaning that its powerful 30W CO2 can print with any powder that’s available on the market. Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Released in 2020, the Gravity SLS 3D printer by Swedish manufacturer Wematter is the most recent printer in our selection. The printer features integrated powder recycling and easy material handling with user-friendly packaging.

Wematter’s cloud-based slicing software automatically optimizes the build area, packing parts efficiently and as close together as possible thanks to advanced algorithms.

Benefits and limits of SLS 3D printing

Main benefits of SLS 3D printing

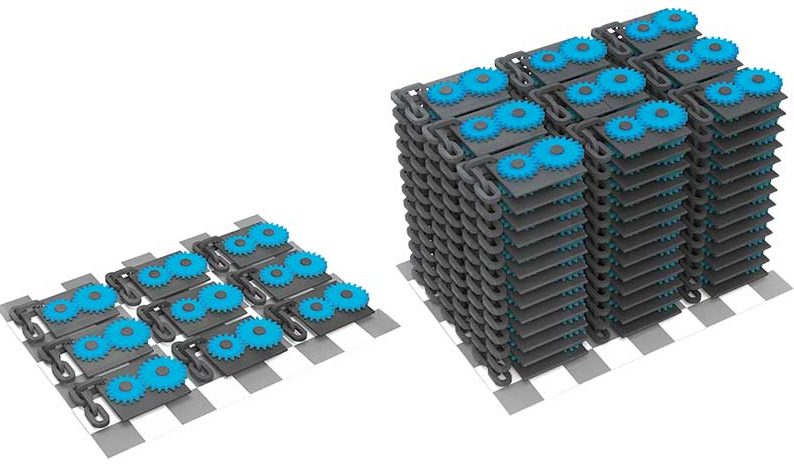

No need for support: 3D printing complex and functional parts

Since unused powder remains in the powder bed, it naturally acts as support for the following sintered layers. This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

It’s also possible to 3D print objects within objects, also known as nesting. This is not possible with other 3D printing technologies such as FFF and FDM (extrusion) or SLA and DLP (resins).

Waste reduction

It is possible to re-use powder that has not been sintered. This significantly reduces material waste and costs compared to other 3D printing techniques. Also, no material is wasted on support structures.

Main limitations of powder SLS 3D printing

Just like any technology, SLS 3D printing has its downsides.

Porosity/rough surface

SLS 3D printed objects are porous, though it is possible to apply sealant to alter their sandy, granular-like surfaces.

Expensive material

The price for one kilogram of PA12 powder can range from around $55 to about $180.

Logistics and post-processing

Due to the volatile nature of powder, extra caution is required when handling the material and taking the final 3D print out of the powder bed. The prints must be depowdered; either manually, which is time-consuming, or with a dedicated powder removal solution.

You may also like:

Guide to post-processing for 3D printed parts

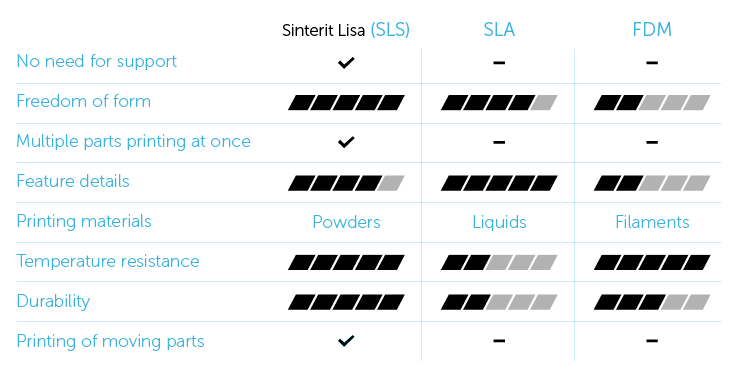

SLS vs FDM vs SLA

SLS vs FDM (FFF)

Compared to Fused Filament Fabrication, SLS can:

- achieve higher quality prints

- provide thinner layers and wall thicknesses

- generate complex 3D prints without the need for support

However, Selective Laser Sintering 3D printers offer much less material choice (and colors).

SLS vs SLA

Compared to stereolithography 3D printing technology, Selective Laser sintering offers:

- thinner wall thicknesses

- complex 3D prints without support structures

That being said, SLS 3D prints have rougher surfaces than SLA 3D prints.

SLS 3D printing: what materials are available?

Main desktop SLS 3D printing powders

Most desktop SLS 3D printers use Polyamide (PA) powdered material, also known as Nylon. The main PA powders available on the market are:

- Nylon PA12

- Nylon PA11

Then, there are composite or “charged” powders, meaning that different materials are mixed with PA. The most common are the following:

- Alumide: PA mixed with aluminum (shiny, metallic appearance)

- Carbonamide: PA reinforced with carbon fiber (stiff and lightweight)

- Nylon 3200: PA filled with glass (more chemical and heat resistant than PA12)

There is also PEBA 2031, a flexible, rubbery, and resistant plastic powder. Some manufacturers produce elastic 3D printing powders (such as Sinterit’s Flexa Black and Flexa Grey) to 3D print shock absorbers, clothing parts, bellows, etc.

Nylon SLS 3D printing material

Nylon, or Polyamide (PA), is the most common powdered material used by SLS 3D printers. It boasts many interesting characteristics:

- Lightweight: Polyamide is a lightweight 3D printing material.

- Robust: this material can bear loads or be used for mechanical parts.

- Flexible: Nylon can bend and come back to its original form.

- Resistance: PA offers good heat and chemical resistance.

Manufacturers generally sell their own, branded powder material.

SLS 3D printing in general

Desktop SLS printers are limited to plastics when it comes to material choice. However, when using larger, more expensive powder industrial 3D printers, it is possible to 3D print metal powder. Some industrial SLS 3D printers are also able to 3D print ceramics.

English

English  Français

Français