Large scale 3D printing: top 5 innovative applications

Although fused deposition modeling is mainly associated with home-based handicraft whizz-kids, being able to print models as wide or as high as 1.7 m brings FDM to the next level!

Desktop machines let engineers and designers quickly prototype their idea and have the mock product live in their hands within hours, but what if you could – for instance – prototype a new race car seat in 1:1 scale?

Here you can read about the 5 most interesting industrial applications of big 3D printers.

#1 Efficient prototyping – customized car solutions

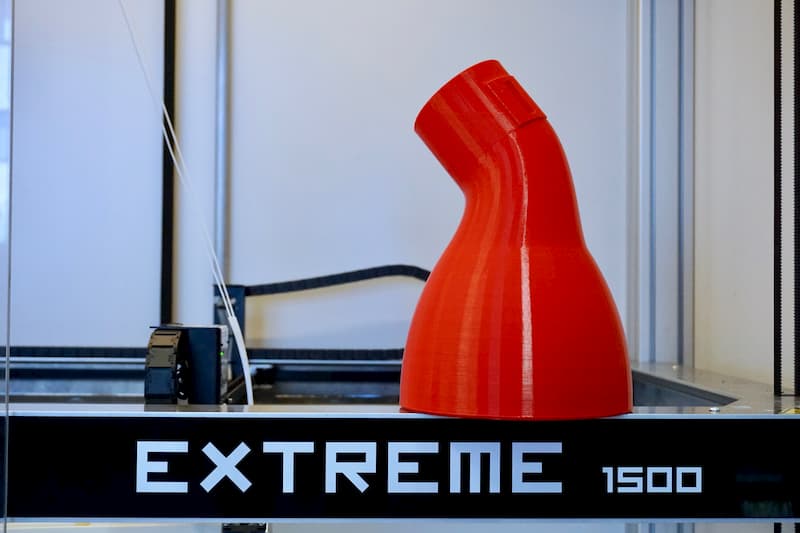

Eventuri, based in the UK, is setting a new benchmark in the aftermarket intake industry for top tier performance cars. The company is constantly developing bespoke intake solutions which bring genuine power and torque increases that are customized for a particular car model.

An important part of developing the new, dedicated solutions is the extensive prototyping. 3D printing allows Eventuri to develop a new model within hours, significantly decreasing product development time.

3D printing is not a novelty for the manufacturer. Eventuri had been using smaller desktop 3D printers, but prototypes always needed to be printed in several parts. This required a lot of gluing and manual handling.

“We needed to print larger prototypes in 1 piece and without worrying about failed prints.”

Bilal Mahmood, founder of Eventuri

Now, with their large 3D printer, Eventuri is able to develop completely new intake solutions within days, and printing them 1:1 as they would look in the actual car.

The 3D printed prototypes are used for fitting tests before the final product from carbon fiber material is created.

#2 Life science educational materials – Triceratops skeleton

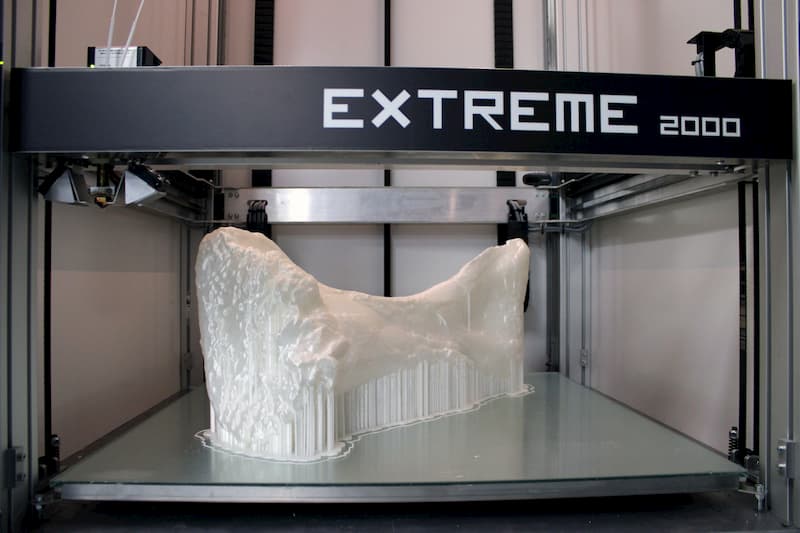

Naturalis is the Dutch national research institute for biodiversity, located in Leiden, Netherlands. A couple of years ago, their researchers found the skeleton of a triceratops in Montana, US, and wanted to display it in the museum among the other dinosaur skeletons. Unfortunately, not all the bones were found, but that is where modern technology comes into the picture.

Over the last couple of years, Naturalis had been using 3D printers, but all their machines had one small issue: build volume. When printing the dinosaur bones, the last thing they wanted was to cut the STL into 10 or more pieces and gluing the printed parts together. That is why large scale 3D printing fitted like a glove.

The missing bones were 3D scanned from other dinosaur skeletons around the world. They were then 3D printed and are now being painted and assembled for exhibition.

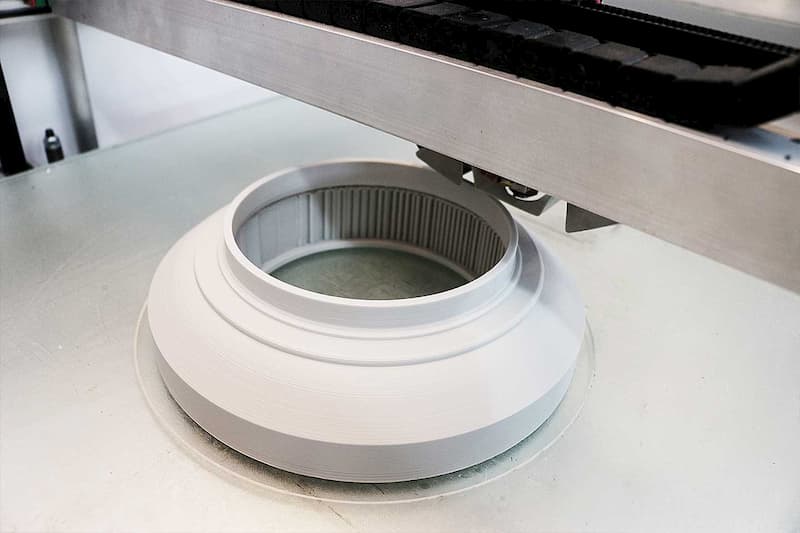

#3 Workflow optimization and improved ergonomics – KLM Engine Services

KLM Engine Services is responsible for the maintenance and overhaul of jet engines from KLM Airlines and their customers.

During the overhaul process, some engine parts need fresh polish and coating. The damaged areas of the parts that need new spraying are being protected by professional heat resistant tape. Service engineers apply and remove this tape manually, which makes it complicated and time consuming.

The original part of the engine was scanned and digitized as a negative model of the area that the coating spray is not supposed to reach. Then, the ‘stencil’ was printed on a large-scale 3D printing machine in a heat-resistant polymer.

#4 More creativity in art – Convela statues for emotional milestones

Convela creates products that orchestrate life’s particular situations in emotional spaces, such as weddings or mourning ceremonies. That is why unique, personalized design is crucial to satisfy their clients’ needs.

“The SOGON is a modular presentation furniture system for emotional moments. The 3D technology allows us to produce our products in a small number of units in synthetic materials.”

Kirsten Hopper, Interior Designer & Illustrator at Convela

Additive technologies might not beat injection molding in the serial production of plastic objects, but it is perfect for low volume manufacturing. Large-scale 3D printing has its benefits when the cost of making a mold for just a couple of pieces would insanely elevate the end unit price.

#5 New product development – 100% electric AppScooter

Located in eco-friendly Amsterdam, Etergo is developing a fully electric scooter, with one of the highest ranges in the segment, an acceleration of 0-45 km in 3.3 seconds. What’s more, living up to its name, this scooter comes with a 7-inch touchscreen and can safely run Android apps. It’s a totally unique electric vehicle.

To create this innovative product, Bolt Mobility invested in the large-format 3D printer to make their large prototypes. These included the saddle, battery module holders, elements of the frame, and AppScooter’s seat. Using a big 3D printer has allowed Bolt Mobility to print these prototypes in full scale, as single pieces.

The seat, for instance, is a large and important part of the scooter, crucial for the comfort of the driver. They were able to 3D print it within 6 days and were immediately able to perform fitting and shape tests.

English

English  Français

Français