Compare

MARS03

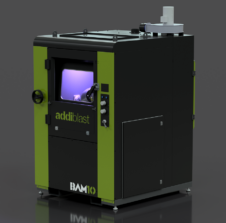

Addiblast

This manufacturer is a Verified partner from our network.

| Category | Depowdering |

| Topic | Post-processing for AM |

| Work area | 580 × 900 × 1000 mm |

| Max. part size | 400 × 400 × 400 mm |

| Country | Slovenia |

Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ...).

upon request

This manufacturer is a Verified partner from our network.

Addiblast offers advanced post-processing for 3D printing, integrating de-powdering, powder recovery, and surface treatment. With over 60 years of expertise, it's designed for efficiency, user-friendliness, and connectivity, serving industries like aerospace, medical, and automotive.

Description

Advanced Automated Powder Removal System: Mars03

The Mars03 is a state-of-the-art solution specifically designed for depowdering of excess powder from highly complex metal structures. This fully automated system is engineered to intricate demands of powder removal in metal processing, offering innovative features and technical specifications that make it a standout choice:

- Servo-Driven Precision and Advanced Monitoring: The Mars03 is equipped with a servo-driven swivel arm that can rotate up to 210° and a Ø 600mm servo-driven rotary table, capable of speeds from 0 to 15 RPM. This setup, combined with a large viewing window, allows for precise and monitored powder removal processes.

- Dual Operational Modes and Smart Control: With both manual and automatic operating modes, the Mars03 offers versatility in handling various tasks.

- Safety and Environmental Compliance: The Mars03 is designed with several safety and environmental features, including HEPA13 exhaust cartridges and an explosion-proof construction. These features ensure that the operation is not only safe for the user but also compliant with environmental safety standards.

It is also equipped with features such as a pneumatic vibrator on the rotary table, a butterfly valve-operated collection hopper, and an electronic control box for managing all machine functions. With its comprehensive set of features, the Mars03 is an ideal solution for industries requiring precise and efficient removal of excess powder from complex metal structures.

Optional

- Inert gas infusion system, that maintain Oxygen level in range 4-2% during operation (Argon or Nitrogen can be used)

- Advanced de-powdering system with pneumatic knocker, electric vibrator and blow off nozzles on swivel arm

- Smart measurment analytics with humidity, temperature, frequency measurement, inert gas, compressed air and electric consumption

Addiblast MARS03 price

Please contact us to get a quote.

Upcoming trade shows

Technical specifications

General |

|

|---|---|

| Model | MARS03 |

| Brand | Addiblast |

| Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ...).

|

Upon request |

| Release date | 2021 |

| Country | Slovenia |

| Status | Available |

| Category | Depowdering |

| Topic | Post-processing |

Performance |

|

|---|---|

| Work area | 580 × 900 × 1000 mm |

| Max. part size | 400 × 400 × 400 mm |

Hardware |

|

|---|---|

| Dimensions | 2000 × 1200 × 2250 mm |

| Weight | 1800 kg |

Video

Meet us at

19 - 22 Nov. 2024

Frankfurt, Germany

English

English  Français

Français