The RangeVision Spectrum, a desktop 3D scanner

Introduction

Today we are doing a hands-on review of the new RangeVision Spectrum. RangeVision has been selling professional 3D scanners for over a decade.

In 2015, they introduced the affordable RangeVision Smart, an entry-level desktop 3D scanner. This product received a warm welcome from the community and made professional 3D scanning accessible to several new users, including museum conservationists, dentists, jewelers, and designers.

| Technology | Structured light |

| Max resolution | 0.072 mm |

| Price | $ 6,039 |

Introduction

Today we are doing a hands-on review of the new RangeVision Spectrum. RangeVision has been selling professional 3D scanners for over a decade.

In 2015, they introduced the affordable RangeVision Smart, an entry-level desktop 3D scanner. This product received a warm welcome from the community and made professional 3D scanning accessible to several new users, including museum conservationists, dentists, jewelers, and designers.

Following this success, in 2017 RangeVision decided to design a more powerful structured light 3D scanner. The Spectrum is fitted with an upgraded video projector and USB 2.0 cameras and is already sold across the globe.

Today we met with Michal Vyplašil, a tech salesman from ABBAS, a 3D scanner reseller and distributor from the Czech Republic. ABBAS offers the whole RangeVision range as well as other brands, such as Artec. ABBAS delivers training and education sessions for every product sold and has very reactive support in Czech, Russian, and English.

Michal came to Dassault Systèmes offices in Vélizy, a town near Paris, famous for its number of very large companies including PSA, Thalès, Bouygues, and General Mills.

At Dassault Systèmes, the demo was hosted at the 3DExperience Lab, a laboratory that nurtures and empowers disruptive projects. The 3DExperience Lab is already home to several 3D printers (including an Ultimaker 2+ and a Markforged Mark One) and 3D scanners. Run by CAD and design experts, the 3DExperience Lab was the perfect place to conduct this hands-on demo.

Michal arrived by plane in Paris, with the Spectrum fitted inside a robust hard case along with all its accessories (excluding the tripod). Therefore, there was no unboxing, but we were able to witness the whole installation process.

Following this success, in 2017 RangeVision decided to design a more powerful structured light 3D scanner. The Spectrum is fitted with an upgraded video projector and USB 2.0 cameras and is already sold across the globe.

Today we met with Michal Vyplašil, a tech salesman from ABBAS, a 3D scanner reseller and distributor from the Czech Republic. ABBAS offers the whole RangeVision range as well as other brands, such as Artec. ABBAS delivers training and education sessions for every product sold and has very reactive support in Czech, Russian, and English.

Michal came to Dassault Systèmes offices in Vélizy, a town near Paris, famous for its number of very large companies including PSA, Thalès, Bouygues, and General Mills.

At Dassault Systèmes, the demo was hosted at the 3DExperience Lab, a laboratory that nurtures and empowers disruptive projects. The 3DExperience Lab is already home to several 3D printers (including an Ultimaker 2+ and a Markforged Mark One) and 3D scanners. Run by CAD and design experts, the 3DExperience Lab was the perfect place to conduct this hands-on demo.

Michal arrived by plane in Paris, with the Spectrum fitted inside a robust hard case along with all its accessories (excluding the tripod). Therefore, there was no unboxing, but we were able to witness the whole installation process.

Discovering the RangeVision Spectrum 3D scanner

The RangeVision Spectrum features all the standard characteristics of a structured light desktop 3D scanner. Its main part is the 3D scanner head, a video projector attached to a rigid aluminum frame, and 2 cameras.

Structured light 3D scanning technology consists of casting a specific light pattern onto the object to 3D scan. Then, the 3D scanner detects the light deformation from 2 different positions, thereby obtaining a precise triangulation and information on the object’s surface. Usually, more power and higher resolution (video projector and camera-wise) translate into better 3D scanning results.

The Spectrum boasts a maximum resolution of 0.07 mm and a maximum accuracy of 0.04 mm. Resolution can be defined as the 3D scanner’s sampling ability to capture a surface, like a grid; the smaller the grid, the better the resolution. Accuracy represents the distance between the measured specific point and its real-life position.

The Spectrum comes with a rugged hard case in which all of its accessories fit, except the tripod. The hard case contains the cables for the 3D scanner head: two USB 2.0 cables to connect the cameras, an HDMI cable for the video projector, and the AC power cable. The Automatic Turn Table (ATT) also includes its own USB 2.0 cable and AC power cable.

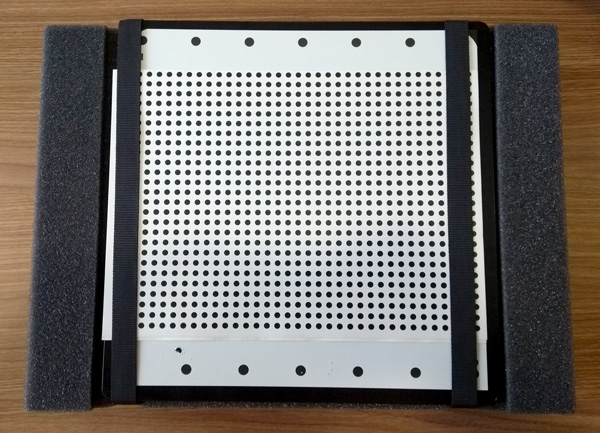

Additionally, an Allen key and calibration plates are also part of the package. The Allen key is required to attach the USB 2.0 cameras to the 3D scanner head frame.

At €5,490, the Spectrum fits nicely between the RangeVision Smart (€2,299) and the RangeVision Pro (over €8,000).

Overview of the RangeVision Spectrum

Setting up the RangeVision Spectrum 3D scanner is quite fast. In a few minutes, the cameras can be secured to the 3D scanner head. It is then possible to connect the tripod thanks to a standard camera screw.

Therefore, the tripod is replaceable with any generic product if the specific use case requires more height or less footprint. Interestingly, RangeVision also sells a table-top tripod, ideal for attaching the 3D scanner to any table and for using the ATT.

Note that users will need no less than 4 USB ports to connect both cameras, the USB stick with the software licenses, and the ATT. To connect a mouse – a must-have for all 3D-related interactions – a USB hub or dock station is a necessity. Also, all of the cables quickly become cumbersome. Therefore, the cable sheaths that RangeVision provides are very useful.

The 3D scanner “head” itself is well-finished, while the video projector is securely encased under a closed plastic cover, which looks like the ones used for each USB 2.0 camera. The whole product feels sturdy and reliable.

It is interesting to note that the Spectrum is compatible with positioning markers, a true advantage for professionals. Indeed, this makes the 3D scanner suitable for large objects and repetitive shapes, which are usually a challenge. It also extends the capabilities to deal with hard-to-scan objects, such as reflective and/or transparent surfaces.

Testing the RangeVision Spectrum

Connecting everything takes about 5 minutes. This includes fixing the 3D scanner head onto the tripod and plugging the cables as well as launching the ScanCenter software. Note that the RangeVision software suite is still two separate programs: ScanCenter, to generate 3D scans, and ScanMerge, to align and merge 3D scans to create a unique mesh.

In the 2017.2 version of ScanCenter and ScanMerge used for the demo, several features were added:

- Users can indicate the ambient temperature to improve calibration accuracy

- Option to repair the model in the MeshFix

- Undo/redo actions added in ScanMerge

- New .rv3d format for ScanMerge

- Model export in .ptx format

Furthermore, the calibration process, program performance, and overall user experience have been improved.

Once the 3D scanner RangeVision Spectrum is on the tripod, the next step is the calibration process. For our specific use case, the 3D scan of a dental imprint, the cameras need to be close together and centered near the video projector’s lens. For this configuration, we used the smallest of the three calibration plates included.

The calibration process is mostly automated, the software telling the user what to do with the calibration plate. It takes a dozen steps consisting of slightly moving the calibration plate in different orientations. Users must focus on the cameras manually. Then, the system automatically adjusts and is ready to 3D scan.

Conclusion

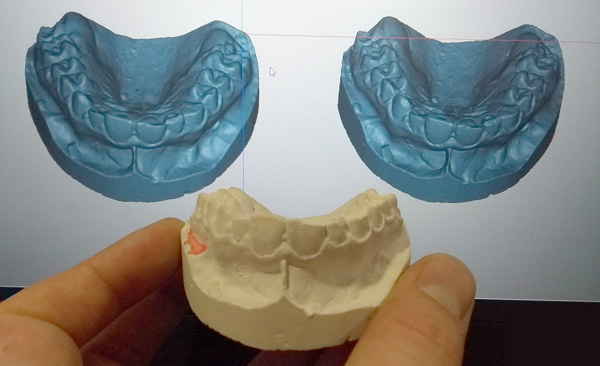

For this hands-on demo, the test object is a plaster dental cast. Even if this white dental impression is easy to capture for structured light 3D scanners, the results we obtained were highly detailed and accurate thanks to its white, uniform texture.

The fixing tools available in the ScanMerge toolbox are also a nice addition to the Spectrum capabilities. They were used to fill up holes and clean geometrical artifacts (small triangles unconnected to the main body of the object).

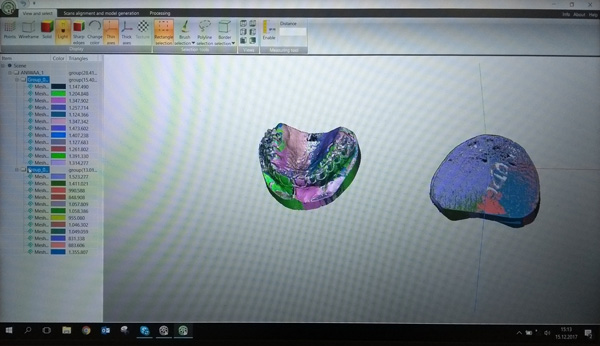

In a few minutes, we obtained the 3D scan in ScanCenter, ready for visualization. We used ScanMerge’s auto-alignment (called registration) feature to assemble the two sets of dot clouds obtained from the dental model into a single orientated group. Then, it was possible to generate the closed mesh. We generated two meshes of the same 3D scan in two resolutions.

The bigger file with the highest resolution is a 1 Gb STL, while the smaller one is 142 Mb. We used the free Meshlab decimation tool to reduce it to 28 Mb so that we could upload it on Sketchfab. ScanCenter also has a built-in feature to reduce model sizes.

by aniwaa

on Sketchfab

The processing speed was approximately 10 times longer for the more detailed mesh, taking approximately 3 minutes. For the small file, it took less than 20 seconds.

In the picture below, we can see the difference between the two models, the high-resolution one being on the right. It has more details and less smoothing.

Aniwaa’s opinion

After some mixed impressions on the RangeVision Smart (very good hardware but unfinished software) we had the chance to perform some more testing after a major software upgrade which took our previous feedback into account.

Since Spectrum uses the same software suite, we were in the known territory and had a good overall experience. Furthermore, a completely new version of ScanCenter and ScanMerge will be available in mid-2018. This version will completely integrate both applications into one.

RangeVision also announced that this major update, free for all users, will have extra features for an easier calibration process. Smoother 3D scan cleaning and preparation will also be available.

In conclusion, we strongly recommend this 3D scanner to all types of users, from enthusiasts to professionals. The performance is on par with the best products of this category, and the price remains affordable for SMEs.

The few competitors of the RangeVision Spectrum on the same price level are the DAVID SLS-3 and the Open Technologies SIAB-FX.

English

English  Français

Français