3D printing for architecture

3D printing for architecture: the applications

There are two main applications of 3D printing for architecture: building low-cost architectural models and creating realistic, detailed architectural models.

Low-cost scale models for architecture are generally used as study models during the creation or design process. Realistic, detailed architectural models are usually kept for the final phase of an architectural project to promote it or for contractors to have the result/scope in mind.

What are the benefits of 3D printing in architecture?

Tangible scale models are essential to many architectural projects as a complement to computer simulations and virtual 3D models. Additive manufacturing makes it quite easy to build cost-effective architectural models with a 3D printer.

Here are some of the main benefits of 3D printing for architecture.

Cost-effectiveness

3D printing enables architects and designers to create low-cost 3D architectural models with a high level of precision. It is for example possible to 3D print several models for different versions of a project.

Having tangible 3D printed architectural models to present to clients can help them visualize the project at different phases of completion.

Faster production

Instead of building scale models by hand, you can 3D print them and work on something else while the 3D printer does all the work. Many architecture firms have 3D printers running 24/7 to efficiently produce 3D-printed versions of their projects.

Easy iteration

If you have a new idea or if your client changes their mind, you can modify the 3D model and reprint it quite easily. 3D printing is a great tool for iterative design, which can apply in architecture.

Accurate and vivid models

You can 3D print architectural models with a high level of detail and choose among a wide range of materials and finishes, depending of course on the 3D printer being used.

That said, 3D printed architectural models require post-processing before they are ready, from basic support removal and cleaning to more advanced finishing operations such as painting and coloring.

3D printing cost-effective architectural models

3D printing makes it possible to test an iterate on different architectural concepts and designs in a cost-effective manner.

It is, however, important to use a reliable 3D printer that offers a decent print resolution if the models have a lot of details. For some types of projects, in urban planning, for example, a 3D printer with a large build volume may be critical.

Fused Deposition Modeling (FDM, also known as FFF) technology is well adapted for 3D printing basic architectural models. Most desktop 3D printers are FDM/FFF and use plastic filament as consumable.

There are resin-based desktop 3D printers as well, which can be a better solution for projects that contain many intricate details. For large-scale and highly detailed projects, large resin 3D printers combine the best of both worlds.

Increased productivity

One of the main advantages of 3D printing in architecture: productivity gains. Indeed, 3D printing can save time in the early design and creation phases by reducing the lead-time for architectural model production and allowing quick tests of concepts and iterations.

While it can take several days to build an architectural model manually using wood or foam, 3D printing can deliver results in just hours. A 3D printer can operate overnight for the larger models, which take longer to print.

Lower production costs

3D printing allows to easily test many concepts early in the project, and quickly identify potential issues, which would be harder to spot on computer simulations.

For this type of 3D printed architectural models used to assess volumes and general structure of the building, no need to use a 3D printer with a very high print resolution or fancy materials. These architectural models need to be 3D printed using single plastic material and a small number of colors, thus keeping the production costs to a minimum.

The 3D printer manufacturer Stratasys claims that modeling costs can be reduced up to 75% by using 3D printing.

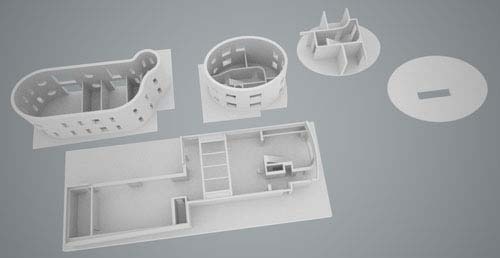

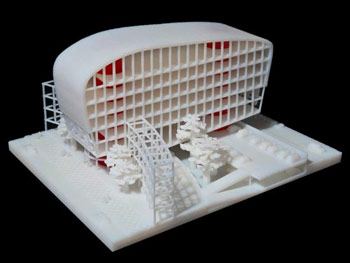

3D printing realistic architectural models

3D printing is often used to produce visually striking architectural models, with the end goal being to promote a project by showcasing a realistic, miniature version of the final result.

In real estate projects, such models can be used in the very early stages of construction to help potential buyers get a clear idea of what the final building will look like. Such architectural models require 3D printers with specific capacities:

- A high print resolution to produce detailed models

- A wide range of 3D printing materials with different properties and textures

- Full-color 3D printing capacity (although the coloring finish is most often done in post-processing)

Again, there is always some degree of post-processing before the 3D printed model is ready for use, especially in the case of durable and realistic 3D printed architectural models.

3D printers using resin-based 3D printing technologies such as SLA or DLP are also often used by architectural firms to produce complex models with a very high level of detail.

Aiding visualization to make a strong impression with 3D printing

3D printed architectural models can be great to visualize the final version of a building or any architectural project in 3D with many lifelike details.

Some advanced 3D printers can even print outdoor terrains and render various textures and colors, for awe-inspiring results.

Showing a beautiful architectural scale model of a building usually helps to promote a project and to attract new clients or investors by making a strong impression.

3D printing is a great new tool for architectural firms willing to improve the model production process but there are some elements to keep in mind:

- The 3D model must be optimized for 3D printing, keeping DfAM (Design for Additive Manufacturing) rules in mind

- The resulting prints often require some post-processing work (cleaning, support removal, assembly, etc.)

Creating architectural models of complex structures

With 3D printers, architects can create architectural models of complex structures such as domes with arches which are almost impossible to produce by hand with conventional fabrication techniques.

For example, MX3D 3D printed an actual metal bridge in Amsterdam in collaboration with Dutch construction company Heijmans.

Note: 3D printers are not intended to replace designers and model makers, but rather to empower them by adding a new powerful machine to their toolbox.

3D printing architectural models cost

3D printed architectural models can be produced in-house or outsourced to an architectural modeling company equipped with additive manufacturing systems. The price of the 3D print will depend on several factors, including:

- Size: The larger the 3D model is, the more expensive it will be to produce (longer print time, more material, …).

- Level of detail: 3D printing a highly complex architectural model takes longer than a basic one and may need to be printed on a specific 3D printer. The model is also likely to require more preparation before being sent for 3D printing.

- Materials: High-quality and/or exotic materials with specific properties are expensive (high resistance, flexibility, etc).

The best 3D printers for architects and the architecture industry

The best 3D printing technology to print architectural models

The best 3D printers for architecture can be either FFF/FDM (using plastic filament materials) or SLA/DLP (using resin materials):

- Extrusion 3D printing (FFF and FDM), using PLA or ABS filament as consumables, is used by most desktop 3D printers and is perfectly suitable for 3D printing architectural models.

- Resin 3D printing (SLA or DLP) is recommended to produce architectural models with a high level of detail.

Features to look out for

To select the best 3D printers for architects, it can be interesting to consider the following features:

- Large build volume: One of the most important things in 3D printing architectural models is the build size. See our selection of the best desktop 3D printers with a large build volume.

- Ability to 3D print fine details: Architectural 3D models often have a high level of detail and thus the 3D printer used to build them should have a sufficient print resolution.

- Wide choice of materials: If you use an FFF 3D printer, you may want it to be compatible with third-party filaments for a wider choice of colors, exotic materials, physical properties, and more.

- Intuitive software: This is particularly important if you’re new to 3D printing. The 3D software you use to prepare your files can make a big difference in terms of quality and time spent.

3D printers for architectural models: prices

An entry-level FFF 3D printer with a large build size can cost several hundred dollars, while large, professional-grade desktop 3D printers generally cost several thousand dollars.

There is also a wide choice of cheap resin 3D printers, professional desktop resin 3D printers, and large-format resin 3D printers.

For even more complex models, benchtop SLS 3D printers (which print with plastic powder) are now emerging in office-friendly formats.

3D printing materials for architecture

To make 3D architectural models, you can choose among a wide range of materials.

- ABS: This is the most popular material for the creation of architectural 3D models. ABS filaments are very common and are affordable.

- Polyamide (Nylon): The 3D models are made from plastic powder and the final surface has a sandy, granular look, and is slightly porous.

- Prime Gray: Also known as Gray Resin, this material can be used to 3D print precise scale 3D models that can easily be painted afterwards. It offers a very smooth final touch.

- Full-color: While this isn’t a material per se, full-color 3D printing enables you to replicate photorealistic colors.

- Transparent resin: This material is generally used to 3D print parts of a final 3D model, such as windows.

3D scanners and 3D software for architects and the architecture industry

3D scanners for architecture

3D scanners are an important part of the 3D printing ecosystem.

Terrestrial laser 3D scanners can be used to capture a whole building before working on a renovation project, for example, or to see the evolution of a construction site over different periods of time. Indoor mobile mapping systems can be used to map a room for re-design or tailor-fit installations.

Virtual 3D models of rooms, homes or commercial buildings can be edited using specific 3D software to simulate the addition of a new piece of furniture for example.

Also, real-estate agencies are increasingly resorting to interior 3D scanning to provide virtual visits of buildings to potential buyers.

3D software for architecture

No matter what type of architectural model you want to 3D print, the first step will be to have a 3D model of the building on your computer.

Some architecture software already offer 3D printing capacities.

For instance, 3D models made with Autocad (Autodesk), SketchUp (Trimble), or HomebyMe (Dassault Systèmes) are compatible with 3D printing.

Some architects the boundaries of 3D design even further by creating their own 3D software. As an example, architect Frank Gehry developed Digital Project, an ambitious architecture 3D software tailored to create highly complex structures that would be impossible to design with traditional 3D software.

Case studies : The Sagrada Familia & HLA

The Sagrada Familia

According to the BBC, 3D printing could allow the Sagrada Familia in Barcelona, Spain, one of the most ambitious buildings in modern architecture, to finally be completed more than a century after the beginning of the project.

“Given the complexity of surfaces and shapes of Gaudi’s original project, working in 2D makes no sense from an architectural point of view.”

Jodi Coll, Chief Architect

Thus, architectural 3D models are quickly and accurately being created thanks to 3D printing.

Henning Larsen Architects

Henning Larsen Architects (HLA) is an architectural firm from Copenhagen which created projects such as the Danish Embassy in Riyadh.

To push the boundaries of architectural design, HLA invested in 3D prototyping technologies.

“This machine has created a much closer link between the physical world and the digital world by allowing us to print color elements and build 3D models of buildings from the beginning of the process.”

Morten Steffensen, HLA engineer

English

English  Français

Français