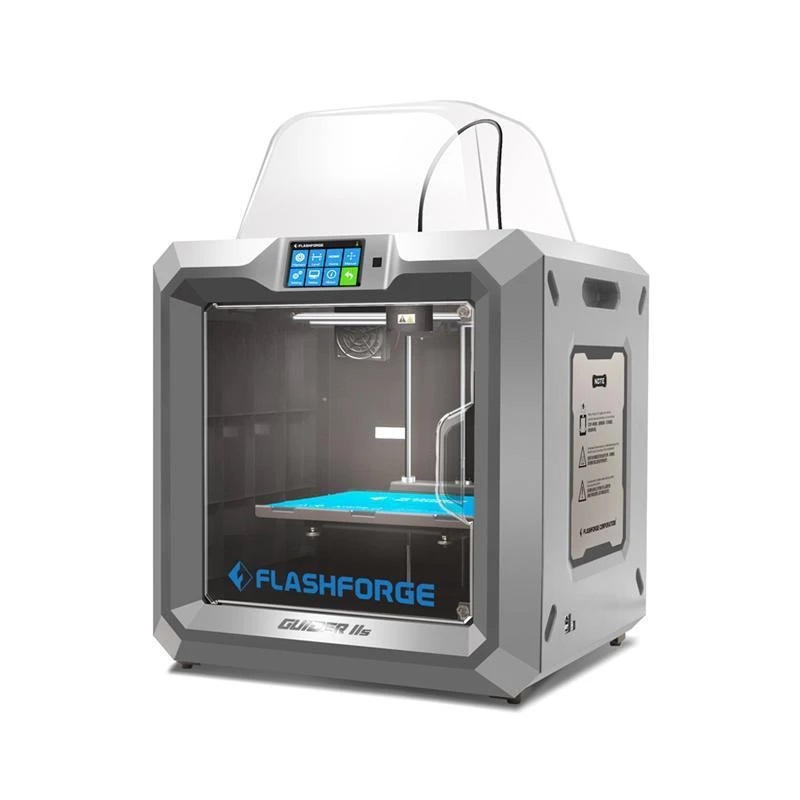

Flashforge Guider IIS: A large desktop 3D printer for low-volume production

Introduction

FlashForge offers quite a wide choice of 3D printers, from entry-level 3D printers like the Adventurer 3 to more professional solutions such as the Guider series.

Today, we’re taking a closer look at the latter after FlashForge recently upgraded the Guider II to the Guider IIS, a reliable large-volume 3D printer for the office.

This desktop 3D printer is equipped with a wide range of professional-grade features to produce high-quality custom parts and prototypes. Thanks to its large build volume, it is even possible to launch small production series.

Exploring the Guider IIS and its features

Large build volume with air filtration

As mentioned above, the Guider IIS boasts a build volume large enough for low-volume production of customized parts.

At 280 x 280 x 300 mm, the build chamber offers plenty of space, and it boasts a HEPA air filtration system to make 3D printing more office-friendly. A HEPA 13 filter is available as well for added filtration.

300°C extruder and hardened nozzle

Certain materials require higher temperatures than standard thermoplastics such as PLA and ABS, and can sometimes be too abrasive for regular nozzles.

Heating up to 300°C, the Guider IIS’ extruder can print more challenging materials– such as PC (Polycarbonate)– than a basic desktop 3D printer. Its toughened nozzle also enables users to print harsher materials like carbon-fiber-filled plastics and other exotic filaments.

Compatible materials include but are not limited to PLA, ABS, PETG, PC, ASA, and HIPS.

Power failure recovery

Have you ever lost several hours of 3D printing time (and filament) to a power outage? If so, you know how frustrating it can be to return to an 80-percent finished part and have to start all over again.

If not, thankfully, you may never have to experience such an exasperating process with the Guider IIS. It saves the 3D printing progress from the very first layer so that when or if there is a sudden power failure, you can simply resume the print from where it left off.

Cloud connectivity

The Guider IIS hosts a range of connectivity options, including USB, Ethernet, and Wi-Fi. Users can therefore access cloud 3D printing functionalities via FlashForge’s bespoke FlashCloud app or popular educational platform PolarCloud.

You can find 3D files, slice them, and launch the 3D printing process remotely while keeping an eye on their progress with the Guider IIS’ onboard HD camera.

Wi-Fi connectivity can also help you ensure your firmware is always up to date with the latest upgrades and features.

You can find out more about the Guider IIS’ features in the FlashForge video below:

Who can use the Guider IIS?

Its professional-grade features and ease of use enable almost anyone to use the Guider IIS, though it is targeted towards schools and professionals, and can even be used for industrial applications.

Below are some real-life examples of how the Guider IIS has been useful to students, professionals, and businesses around the world.

Guider IIS for educational purposes

The Shanghai Jiao Tong University has made 3D printing widely available to its students by establishing what they call a “Student Innovation Center”. Students are each given 1kg of filament each year, which can be used on any of the dozen FlashForge 3D printers available at the center.

According to the university, over 3,000 objects were 3D printed at the Student Innovation Center during a three-month period by more than 800 students. Examples of such objects include cranial repair designs, surgical training models, osteotomy guide plates, and much more.

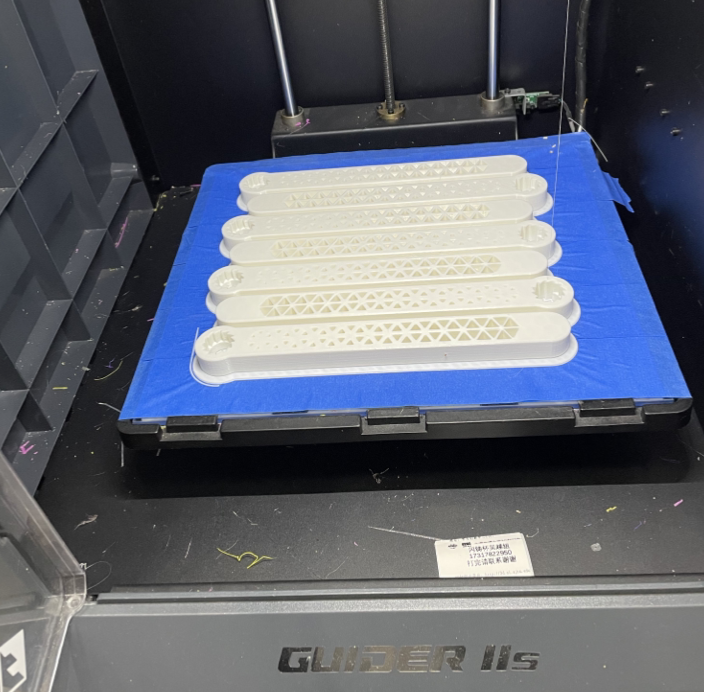

Rapid prototyping and model proofing with the Guider IIS

Akribis Systems designs and manufactures direct-drive motors, positioning systems, and other components across numerous industries. They have been using their FlashForge Guider IIS for rapid prototyping and model proofing to speed up their processes.

Some examples include a hinge for a military communication system, a cover plate for a wind turbine controller, and a turntable cable adapter.

Once their teams validate the designs, Akribis can confidently launch large production series with their heavy industrial machines.

Low-volume manufacturing

After observing a serious shortage of protective medical equipment during the first COVID outbreak in China, the Hunan Yunjian Group (HYG) decided to speed up its production by leveraging 3D printers.

They installed over 200 FlashForge Guider II Series 3D printers and were able to increase their output from 600 to 2,000 goggles a day– equalling a +230% production boost.

Find out more about the Guider IIS

For more information on the Guider IIS, please visit the official FlashForge website.

English

English  Français

Français