Ceramic 3D printing 2024: guide and ceramic 3D printer selection

What is ceramic 3D printing?

Today, ceramic 3D printers are mostly expensive industrial additive manufacturing systems. These systems vary in the 3D printing technologies they use to 3D print ceramic material: extrusion, binder jetting, photopolymerization, and powder sintering.

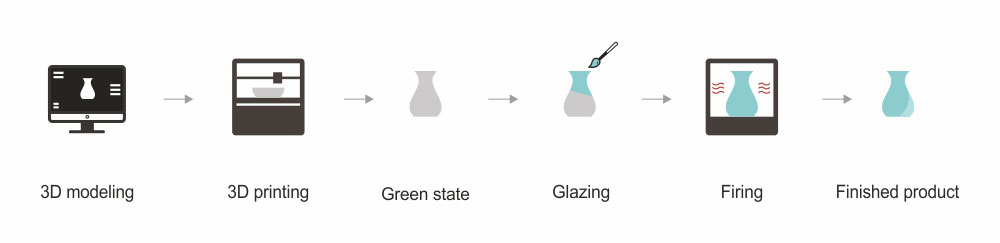

However, 3D printing is only part of a longer manufacturing process. Ceramic 3D printers generate green parts, meaning that they must go through heavy post-processing steps in order to reach their final form. One of these steps, for instance, is firing the ceramic part or prototype in a high-temperature kiln.

Ceramic material is widely used in a number of industries. Of course, some of the first applications that come to mind are pottery or kitchenware – but ceramics are literally everywhere and in many different forms. They can be used for industrial use in automobiles or aerospace, for example, and some ceramics are frequently used in healthcare for medical devices and tools.

This guide includes a comprehensive selection of ceramic additive manufacturing solutions and clay 3D printers for professionals.

The best ceramic 3D printers in 2024

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| WASP

Product data validated by the manufacturer.

| DeltaWASP 2040 Clay | ⌀ 200 x 400 mm | Italy | $ 3,500 | Quote |

| StoneFlower | 4.0 Multimaterial 3D printer | 500 × 500 × 800 mm | Germany | $ 4,000 | Quote |

| 3DPOTTER | 3D PotterBot 10 Pro | 415 × 405 × 500 mm | – | $ 6,105 | Quote |

| VormVrij | LUTUM 5 | 430 × 450 × 500 mm | Netherlands | $ 9,900 | Quote |

| Tethon 3D | Bison 1000 | 110 × 60 × 130 mm | United States | $ 16,900 | Quote |

| Lynxter

Product data validated by the manufacturer.

| S600D | ⌀ 390 x 600 mm | France | $ 57,000 | Quote |

| Rapidia

Product data validated by the manufacturer.

| Conflux 1 | 200 × 280 × 200 mm | Canada | $ 99,000 | Quote |

| Pollen AM

Product data validated by the manufacturer.

| Pam Series MC | ⌀ 300 x 300 mm | France | $ 140,000 | Quote |

| Admatec | ADMAFLEX 130 | 160 × 100 × 400 mm | Netherlands | $ 150,000 | Quote |

| Lithoz | CeraFab 7500 | 76 × 43 × 170 mm | Austria | $ 250,000 | Quote |

| XJet | Carmel 700C | 500 × 140 × 200 mm | Israel | $ 599,000 | Quote |

| 3DCeram

Product data validated by the manufacturer.

| C1000 FLEXMATIC | 320 × 320 × 200 mm | France | upon request | Quote |

| Desktop Metal | X160Pro | 500 × 800 × 400 mm | United States | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|---|

| WASP

Product data validated by the manufacturer.

| DeltaWASP 2040 Clay | Paste deposition | ⌀ 200 x 400 mm | Italy | $ 3,500 | Get a quote |

| StoneFlower | 4.0 Multimaterial 3D printer | Paste deposition | 500 × 500 × 800 mm | Germany | $ 4,000 | Get a quote |

| 3DPOTTER | 3D PotterBot 10 Pro | Paste deposition | 415 × 405 × 500 mm | – | $ 6,105 | Get a quote |

| VormVrij | LUTUM 5 | Paste deposition | 430 × 450 × 500 mm | Netherlands | $ 9,900 | Get a quote |

| Tethon 3D | Bison 1000 | DLP | 110 × 60 × 130 mm | United States | $ 16,900 | Get a quote |

| Lynxter

Product data validated by the manufacturer.

| S600D | Material Extrusion | ⌀ 390 x 600 mm | France | $ 57,000 | Get a quote |

| Rapidia

Product data validated by the manufacturer.

| Conflux 1 | Paste deposition | 200 × 280 × 200 mm | Canada | $ 99,000 | Get a quote |

| Pollen AM

Product data validated by the manufacturer.

| Pam Series MC | Material Extrusion | ⌀ 300 x 300 mm | France | $ 140,000 | Get a quote |

| Admatec | ADMAFLEX 130 | DLP | 160 × 100 × 400 mm | Netherlands | $ 150,000 | Get a quote |

| Lithoz | CeraFab 7500 | DLP | 76 × 43 × 170 mm | Austria | $ 250,000 | Get a quote |

| XJet | Carmel 700C | NPJ | 500 × 140 × 200 mm | Israel | $ 599,000 | Get a quote |

| 3DCeram

Product data validated by the manufacturer.

| C1000 FLEXMATIC | SLA | 320 × 320 × 200 mm | France | upon request | Get a quote |

| Desktop Metal | X160Pro | Binder Jetting | 500 × 800 × 400 mm | United States | upon request | Get a quote |

Industrial ceramic additive manufacturing systems

This ceramic additive manufacturing system uses DLP 3D printing technology.

Compatible materials include aluminum oxide, zirconium oxide, silicon oxide, a combination of aluminum and zirconium, hydroxyapatite and silica based materials for investment casting.

Canada-based Rapidia offers an interesting and unique way to 3D print ceramics (and metal). They use a water-based ceramic paste, which eliminates the need for chemical debinding.

The water evaporates during the 3D printing process, so the part only needs to go through the furnace in order to completely solidify and attain its final form.

The Lithoz CeraFab 7500 is an industrial-grade 3D printer featuring Lithography-based Ceramic Manufacturing (LCM) technology. This technology uses photosensitive resin to 3D print ceramic parts.

According to Lithoz, this ceramic additive manufacturing system is plug-and-play.

This industrial 3D printer from Israel breaks ceramic and metal material down into nanoparticles, in a patented process called NanoParticle Jetting. These particles are then mixed to XJet’s proprietary liquid, which is then jetted layer by layer through thousands of nozzles.

XJet’s technology produces parts of with an outstanding level of detail and accuracy.

The C1000 FLEXMATIC is a 3D printer produced by 3DCeram, a manufacturer based in France.

It uses the Stereolithography technology to produce alumina, aluminum nitride, hydroxyapatite, silica-based, silicon nitride, tricalcium phosphate, zirconia and ceramics parts using resin feedstock.

It offers a build volume of 320 × 320 × 200 mm.

Desktop Metal X160Pro overview

The X160Pro is a 3D printer produced by Desktop Metal, a manufacturer based in the United States.

It uses the Binder jetting (single-step) and Binder jetting (multi-step) technologies to produce aluminum nitride, sand, ceramics, bronze, gold, aluminum, cobalt chrome, copper, inconel, nickel, silver, steel, titanium, tungsten and glass parts using powder and sand feedstocks.

It offers a build volume of 500 × 800 × 400 mm.

Professional desktop ceramic 3D printers

German-based StoneFlower manufactures print heads dedicated for suspensions and pastes, clay printing add-ons for desktop 3D printers, and the user-friendly Multimaterial 3D printer.

The StoneFlower 3D printer comes with a touchscreen, WiFi/Ethernet, precise mechanical feed system, and optional dual extruder.

Custom build sizes are available upon request as well as closed casings.

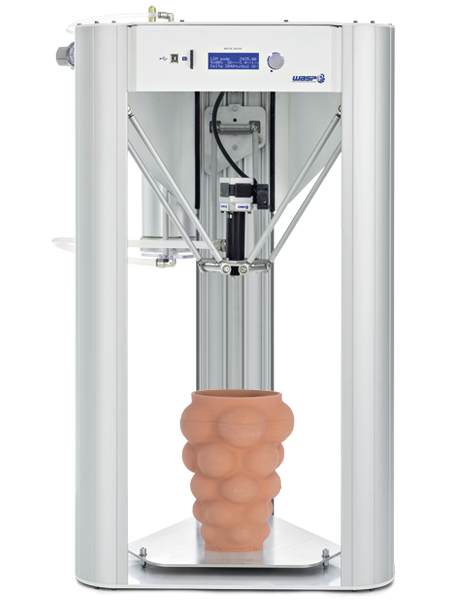

WASP is an Italian manufacturer specializing in delta 3D printers and clay 3D printing materials (and even concrete 3D printing). Their Delta WASP 2040 Clay is a compact and affordable solution for professionals.

A clay printing kit is also available for users that already own a 3D printer.

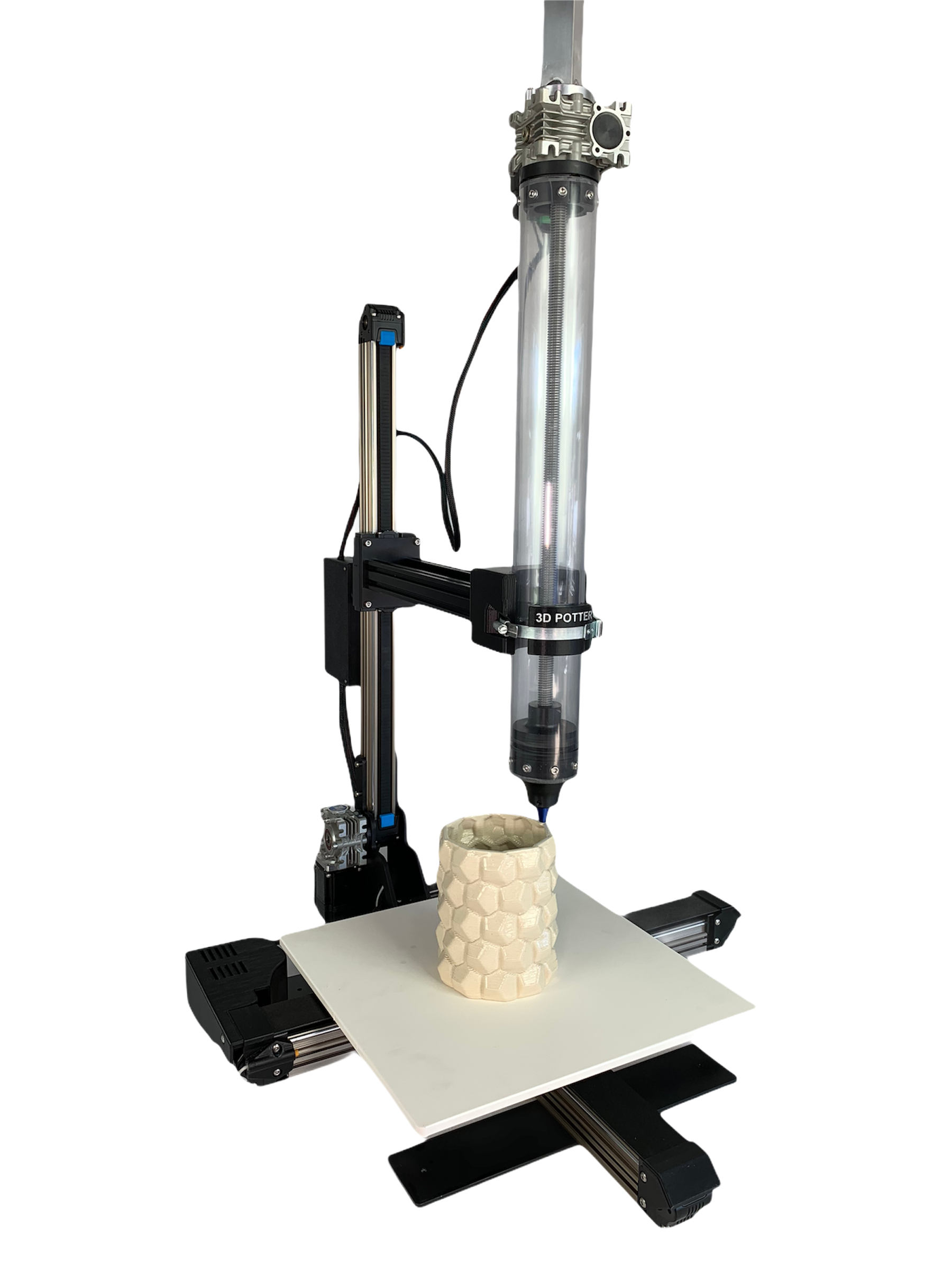

This ceramic 3D printer uses a stationary paste extruder, meaning that clay comes directly out of the nozzle without the need for air compressors or hoses.

The syringe-like extruder is able to contain a maximum of 2000 mL of material.

The VormVrij LUTUM 5 is one of the many clay 3D printers manufactured by Dutch brand VormVrij. This model is equipped with a large intuitive touchscreen, Wi-Fi connectivity, and high-quality components.

Its 316 grade Stainless Steel extruder uses moisture-free 6Bar compressed air to push clay through its nozzle.

The Bison 1000 is a desktop ceramic resin 3D printer from the US. Tethon 3D, the manufacturer, has been developing professional resins for a few years already and this is their first commercialized 3D printer.

Proprietary resins include materials such as porcelain, earthenware, alumina, and others.

The S600D by French manufacturer Lynxter is an all-in-one 3D printer that is packed with features. Its main characteristic is its ability to 3D print high-performance materials such as PEEK or PEI, with a high-temperature extruder, print bed, and chamber.

Its special paste-material print head enables it to 3D print ceramic materials as well.

Pollen AM is a French manufacturer that has been producing pellet 3D printers since 2013. Their Pam Series MC is a delta-style 3D printer (cylindrical build volume) that can print both ceramics and metals, and even thermoplastics.

It extrudes injection-molding pellets instead of ceramic 3D printing filament, which is a more affordable material format than powder or filament, for example.

Special mentions

Nanoe Zetamix

Nanoe produces several ceramic-infused filaments that can be printed by almost any desktop FFF 3D printer. These filaments are part of Nanoe’s Zetamix line and materials include Zirconia, black Zirconia, and Alumina, and even a metal-based filament (Stainless Steel).

After parts are printed, debinded, and sintered, they are 99% dense.

Voxeljet

Voxeljet specializes in industrial AM systems for sand molds, though the majority of their printers are capable of printing ceramic materials.

The most compact Voxeljet system is the VX200, which already boasts very large dimensions: 1,700 x 900 x 1,500 mm. Pricing starts at around $150,000.

Kwambio

For those looking for Kwambio, the company is in a delicate financial position. Kwambio is an additive manufacturing company from Ukraine with headquarters in New York. Their online ceramic 3D printing service enables users to choose from glossy, matte, opaque, or unglazed finishes.

The Kwambio Ceramo Zero ceramic 3D printer never officially made it to market.

Ceramic 3D printing process

There are several 3D printing technologies available to 3D print ceramic material:

- Paste extrusion: a paste extruder deposits layers of ceramic onto a build plate.

- Powder sintering: the ceramic is in a powdered form and is sintered layer by layer.

- Binder jetting: the 3D printer deposits layers of binding agent upon layers of powder.

- Photopolymerization: a light source solidifies a mix of resin and ceramic powder layer after layer.

Most industrial ceramic 3D printers use either binder jetting or powder sintering technologies.

More on ceramic AM technologies:

Choosing a ceramic AM technology: an application-centered approach

As mentioned earlier, ceramic 3D printers create green parts. These green parts must go through different steps to reach their final form:

- Firing: in some cases, this step must be repeated more than once.

- Glazing (optional): professionals may choose to cover the object with glaze to give it a special color or finish, such as matte or glossy.

Applications for ceramic 3D printing

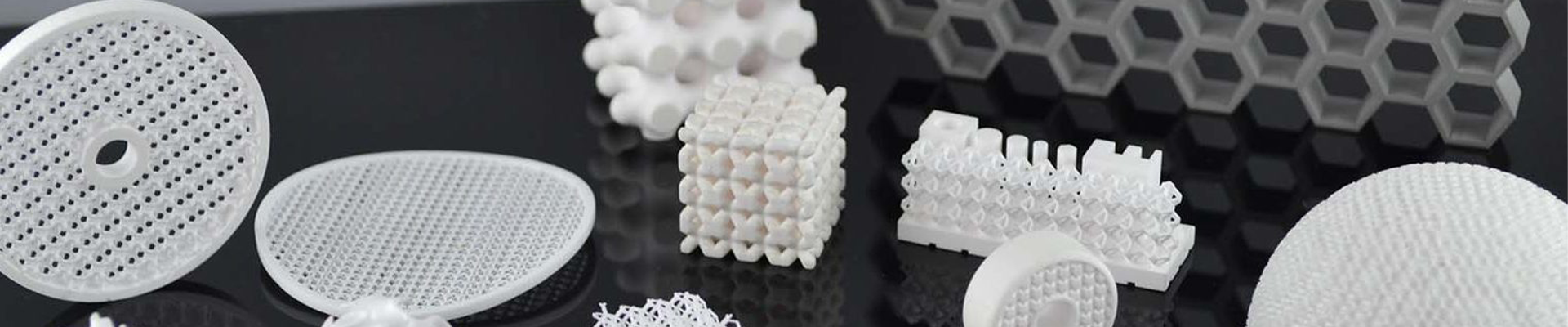

In general, ceramic materials provide a number of properties:

- high strength and dimensional stability

- low density

- chemical stability

- high electrical insulating capacity

- high resistance to abrasion and corrosion

Therefore, ceramic 3D printing suits a wide variety of applications. These applications include engineering in industries such as aerospace, automotive, chemical, electrical, environmental, medical, and more.

Of course, artists can also benefit from ceramic 3D printing (clay printing) for pottery and sculptures.

Here, we are highlighting two industries where ceramic 3D printing seems to be gaining prominence:

Ceramic art, pottery, and sculptures

For hundreds of years, we have been using clay to create beautiful and/or functional objects. Dutch designer Olivier van Herpt, for example, uses his ceramic 3D printer to create impressive vases. Ceramic material is also used in the luxury industry for watches and jewelry.

Biomedical

There are a number of applications with 3D printing ceramics when it comes to the medical industry. For instance, patients can benefit from custom implants made of calcium phosphates, a material that is very close to human bone composition. Furthermore, it’s possible to control the implant’s porosity.

This means 3D printed bone substitutes will have a low chance of rejection from a body’s immune system. 3DCeram illustrates this in their medical case study.

Professional ceramic 3D printing services

Industrial ceramic additive manufacturing systems are very expensive, and it may not always make sense for a business to invest in one. Some ceramic printer manufacturers give professionals the opportunity to use their machines through ceramic 3D printing services.

Users just have to send their 3D model to the service, choose the material, and wait until they receive the final product. Ceramic 3D printer manufacturers such as 3DCeram, Admatec, DDM Systems, Kwambio, Lithoz, Prodways, and Voxeljet provide this type of service.

A few 3D printing service bureaus offer ceramic printing options, too:

- Shapeways

- iMaterialise

- OsseoMatrix

- WZR CerPrint

English

English  Français

Français